Method and system to detect and measure piping fuel leak

A technology of fuel pipeline and fuel delivery, which is applied in the direction of turbine/propulsion fuel delivery system, charging system, combustion method, etc., and can solve problems such as leakage and failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

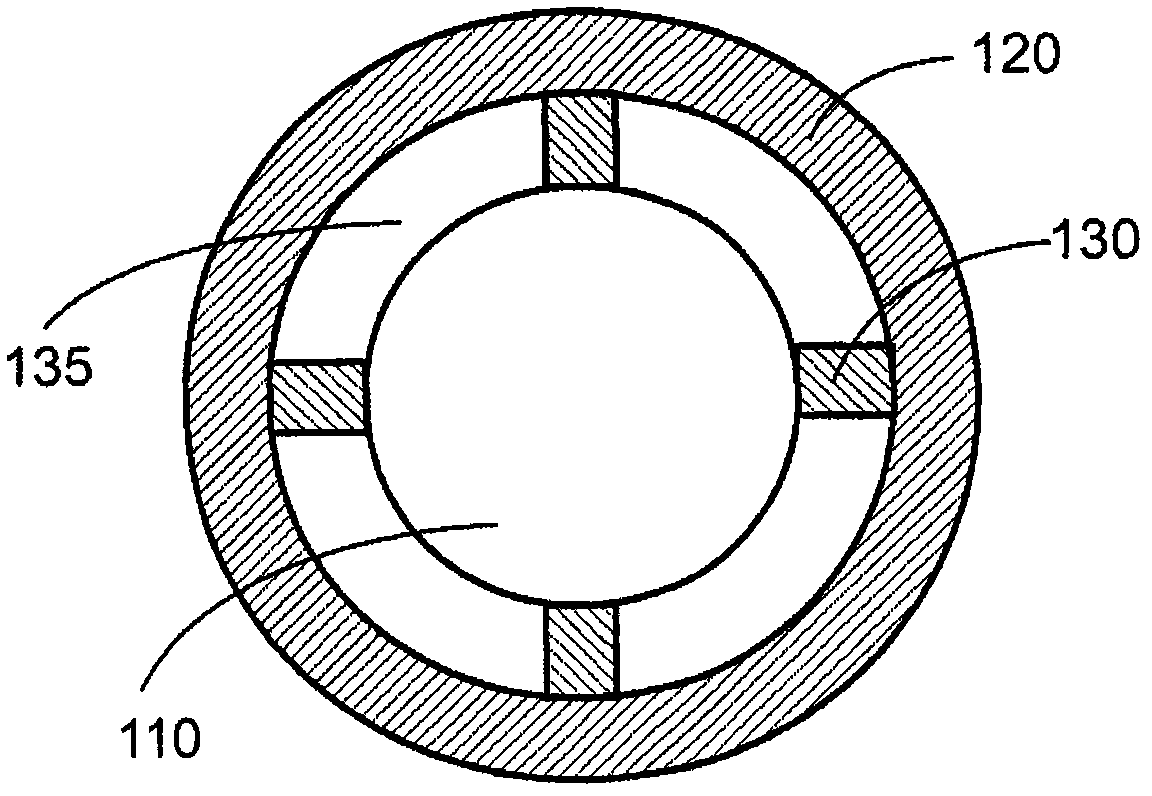

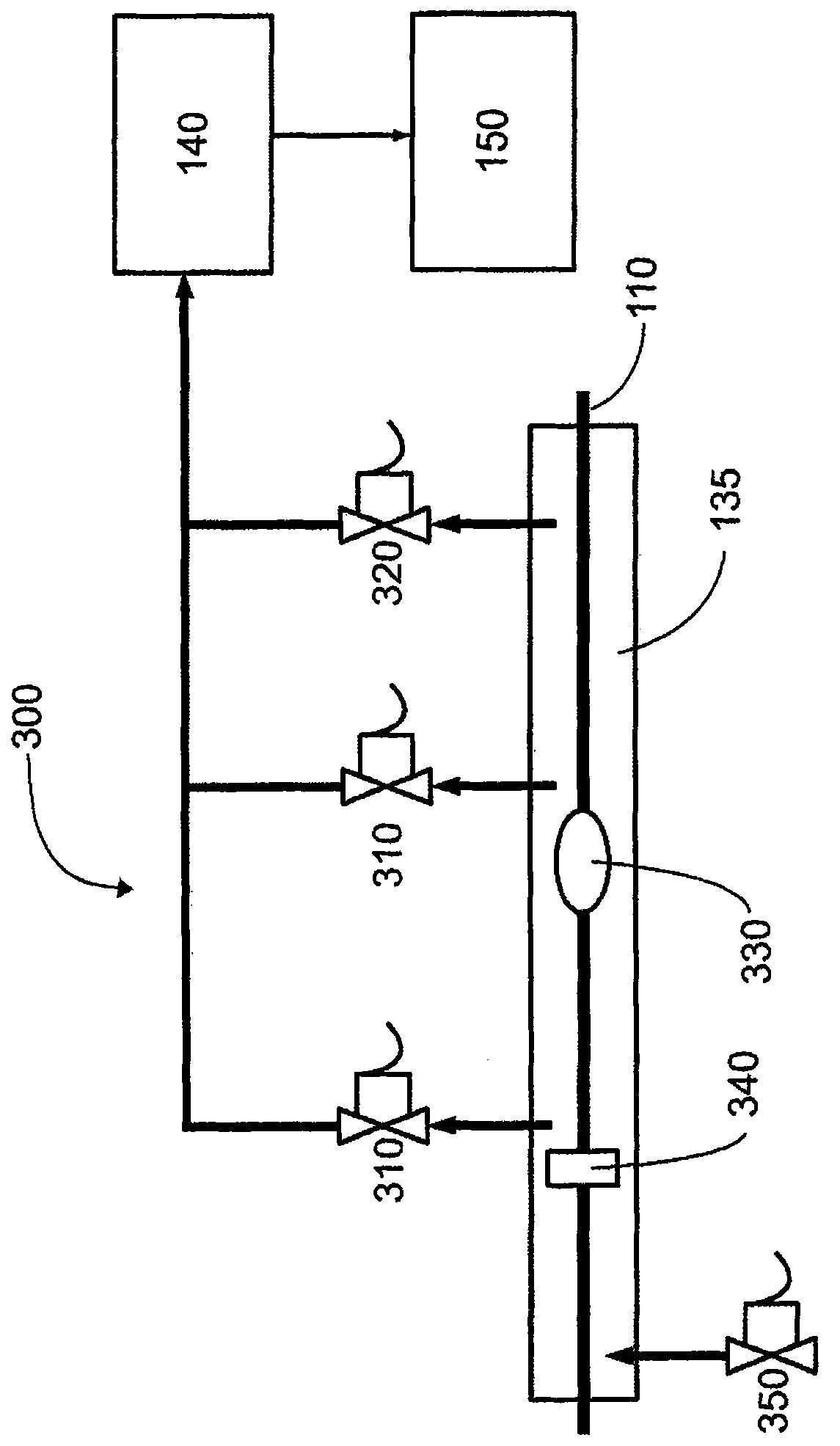

[0038] Novel methods and systems for measuring and detecting fuel pipeline leaks are described. The methods and systems utilize continuous and / or periodic measurements of fuel pipelines to detect leaks of fuel, such as liquid and / or gaseous hydrocarbons, hydrogen, and carbon oxides. Typically, the fuel conduit is enclosed in an airtight seal such that a passage is formed through the fuel conduit and the seal. Measurements can be made using known industrial analyzers for hydrocarbons and other combustible gases and leak detectors. The pressure drop in the channel is compensated by controlling the feed flow into the channel to match the pumping rate of the analyzer. The temperature and motion of the gas sample can be controlled by heating the incoming air. The system may include a control valve for leak source location.

[0039] figure 1 shows one embodiment of a fuel line arrangement for detecting fuel line leaks according to a non-limiting aspect of the invention, and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com