Flexible control loop of hydraulic cylinder and engineering mechanical equipment

A telescopic control, hydraulic cylinder technology, applied in mechanical equipment, fluid pressure actuating devices, servo motor components, etc., can solve problems such as pin hole position failure, system reliability reduction, and inability to latch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

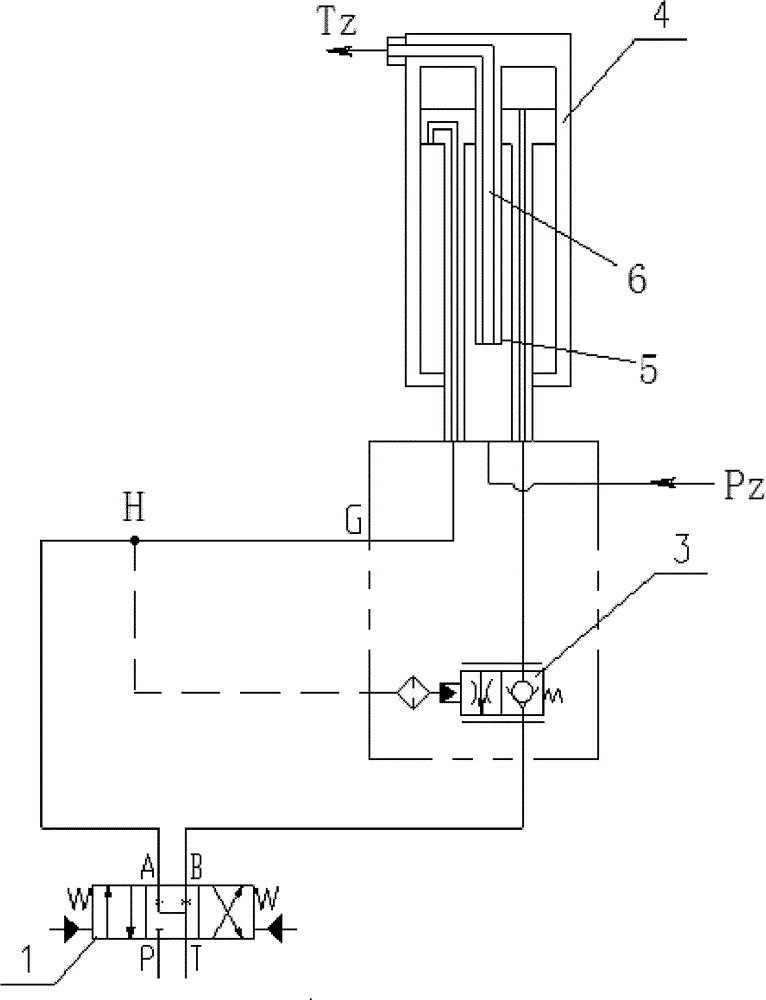

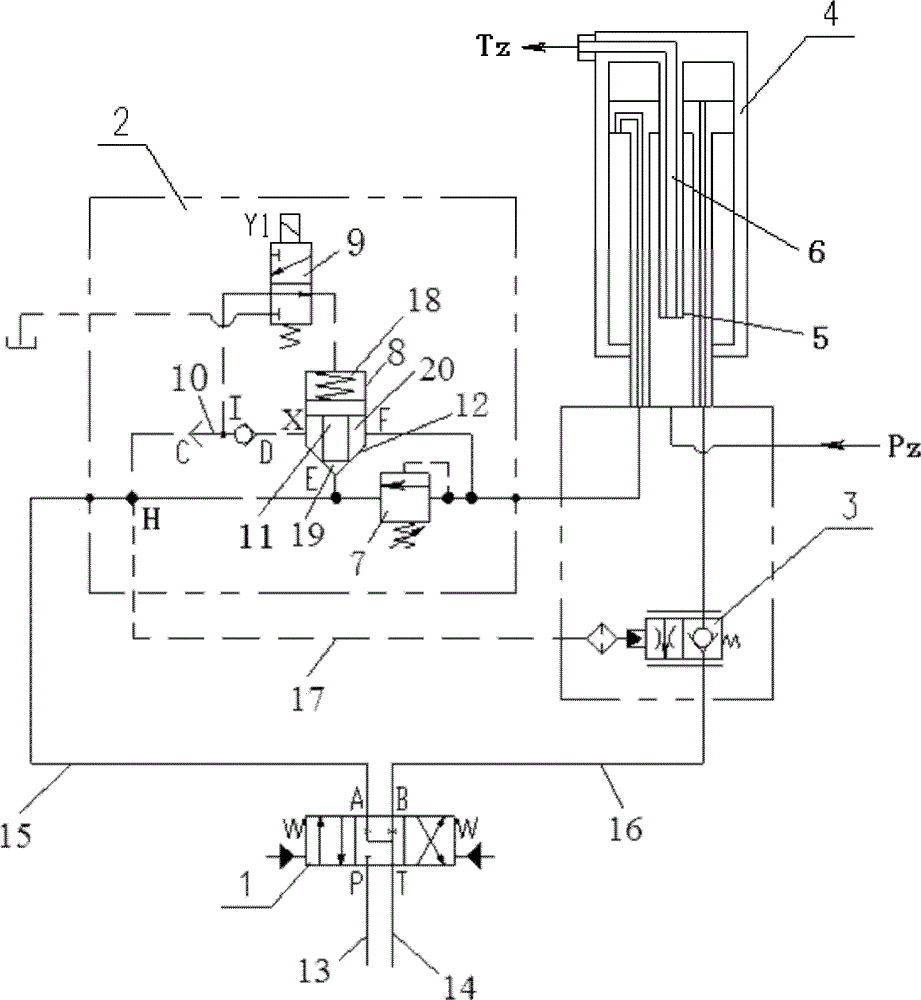

[0045] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0046] First of all, it needs to be explained that the telescoping control circuit of the hydraulic cylinder of the present invention belongs to the field of hydraulic pressure, and its substantive technical idea lies in the hydraulic connection relationship, not in the specific mechanical structure. For example, as far as the stroke lock valve used in the hydraulic cylinder expansion and contraction control circuit of the present invention is concerned, its composition should be understood from a broad hydraulic principle, and should not be limited to the specific form shown in the accompanying drawings, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com