Novel valveless material self-absorbing conveying device

A conveying device and valveless technology, which is applied to liquid variable displacement machinery, piston pumps, machines/engines, etc., can solve problems such as aggravating the difficulty and cost of oil spill recovery and environmental restoration, and increasing the degree and scope of leakage pollution. , to achieve the effect of simple structure, reliable structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

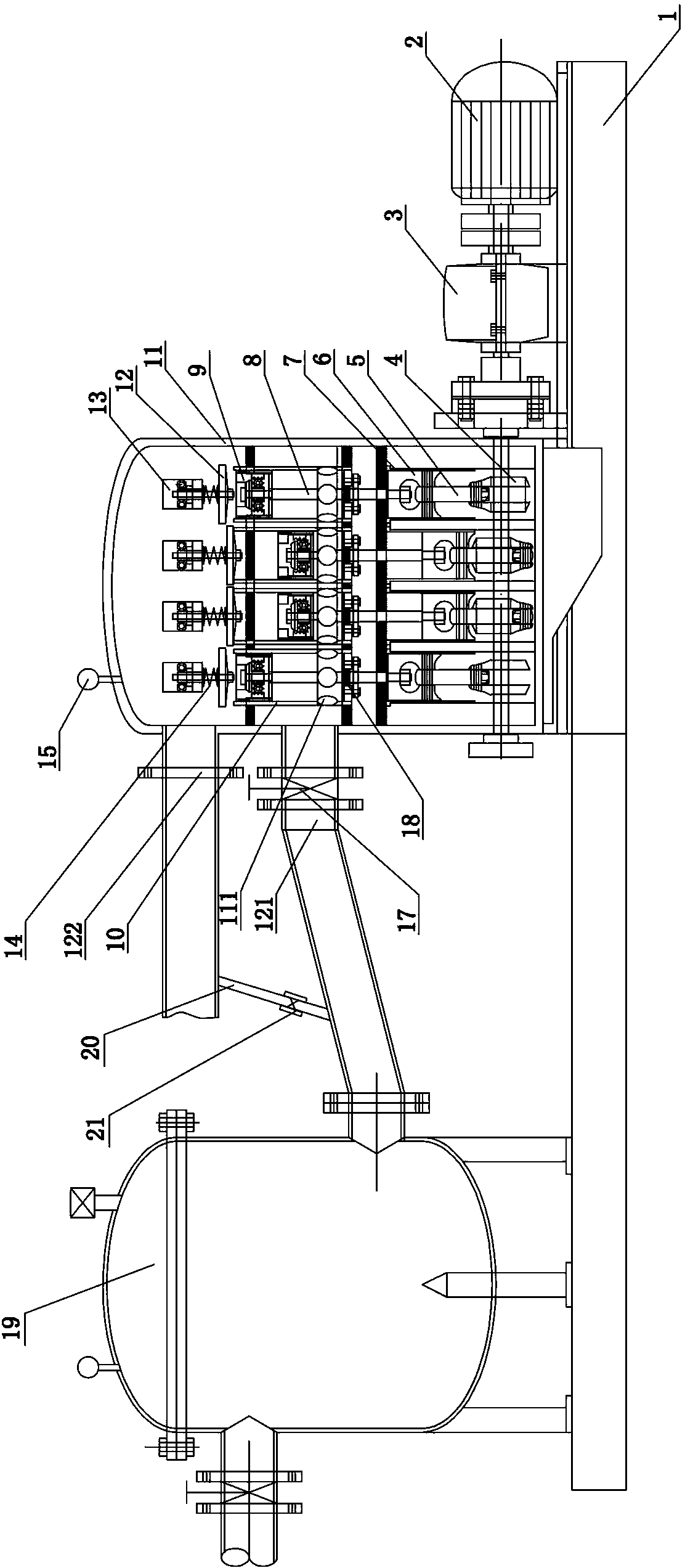

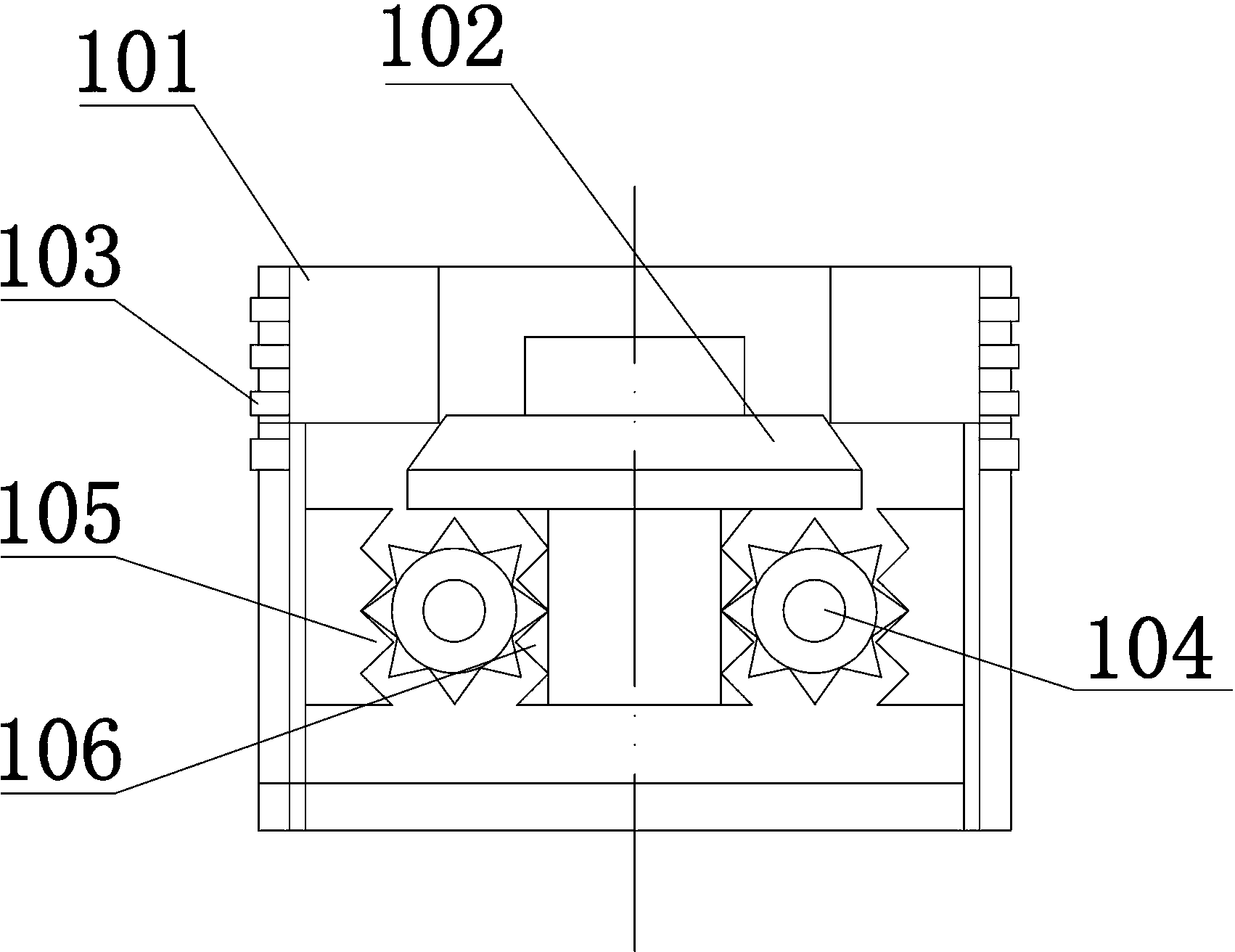

[0020] like figure 1 , figure 2 Shown: a new type of valveless self-priming material conveying device, characterized in that it includes a pressurized storage tank 19, a transmission mechanism, a linkage mechanism, and a fixing mechanism; the transmission mechanism is connected with the linkage mechanism; The mechanism is connected to the fixed mechanism; the pressurized storage tank 19 is connected to the transmission mechanism.

[0021] Described transmission mechanism comprises support 1, explosion-proof motor 2, speed changer 3, crankshaft 4, crankcase 11; Explosion-proof motor 2 is fixedly connected on the support 1; Speed changer 3 is fixedly connected on the support 1, and with explosion-proof motor 2 are connected; the crankshaft 4 is connected with the rotating shaft of the explosion-proof motor 2, and is located in the crankcase 11; the crankcase 11 is connected to the base 1; the crankcase 11 is provided with an inlet pipe 121 and an outlet pipe 122, the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com