Combustion engine without crank shaft connection rod

An internal combustion engine and no crankshaft technology, which is applied in the direction of mechanical equipment, machines/engines, etc., can solve the problems of not considering reciprocating inertial force vibration, low mechanical transmission efficiency, and unfavorable overall machine layout, etc., achieving significant weight reduction effect and saving layout space , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

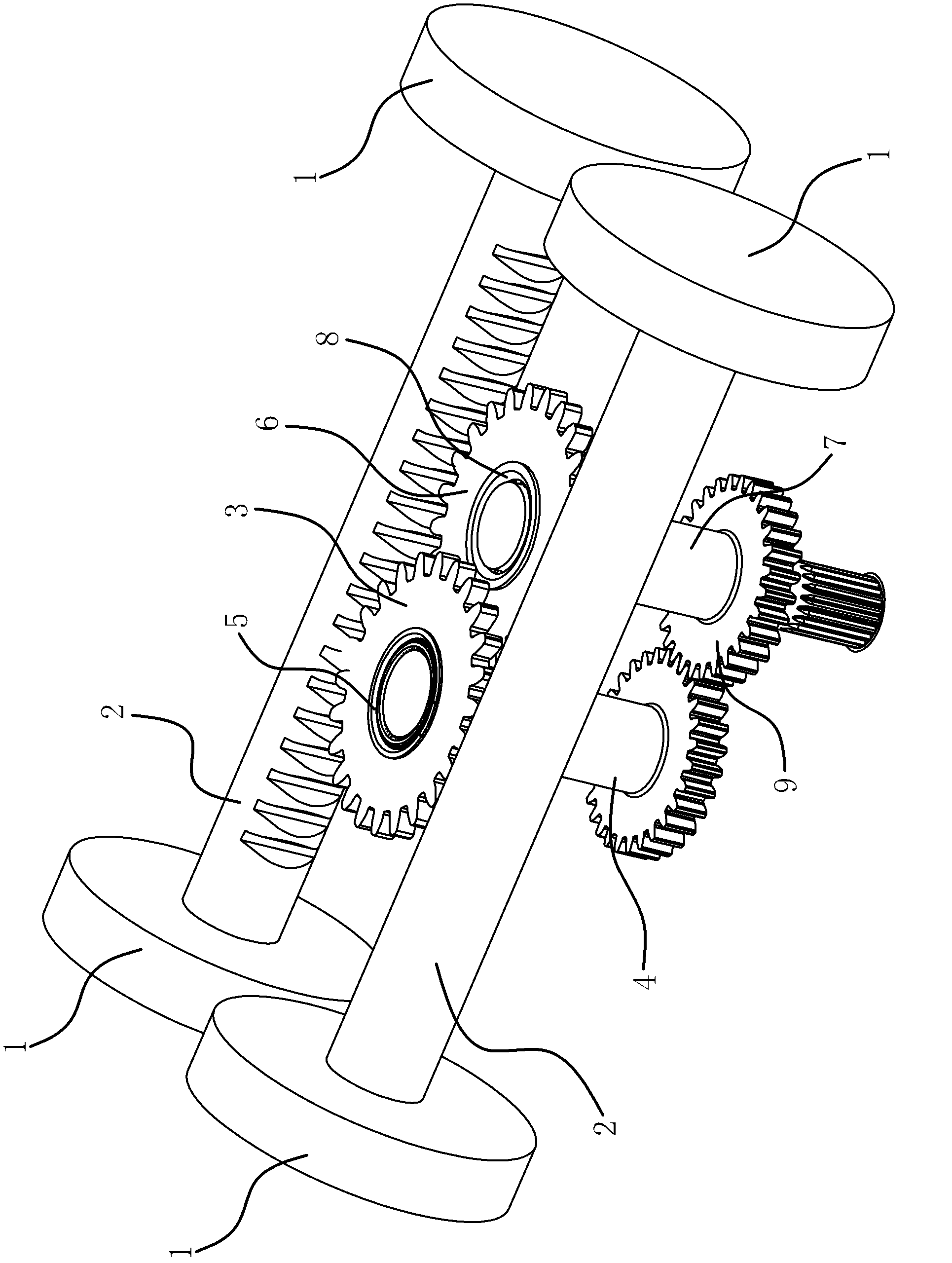

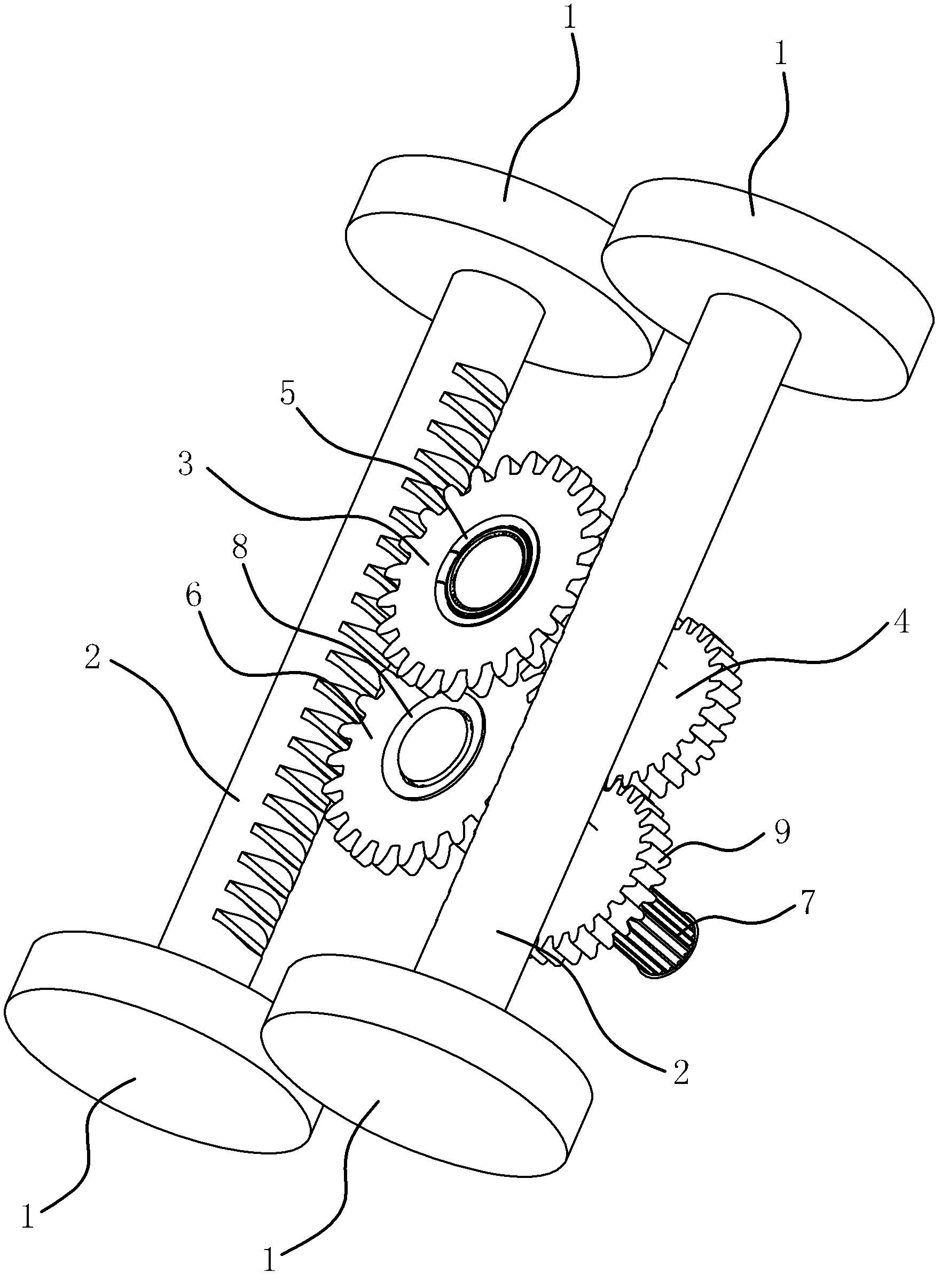

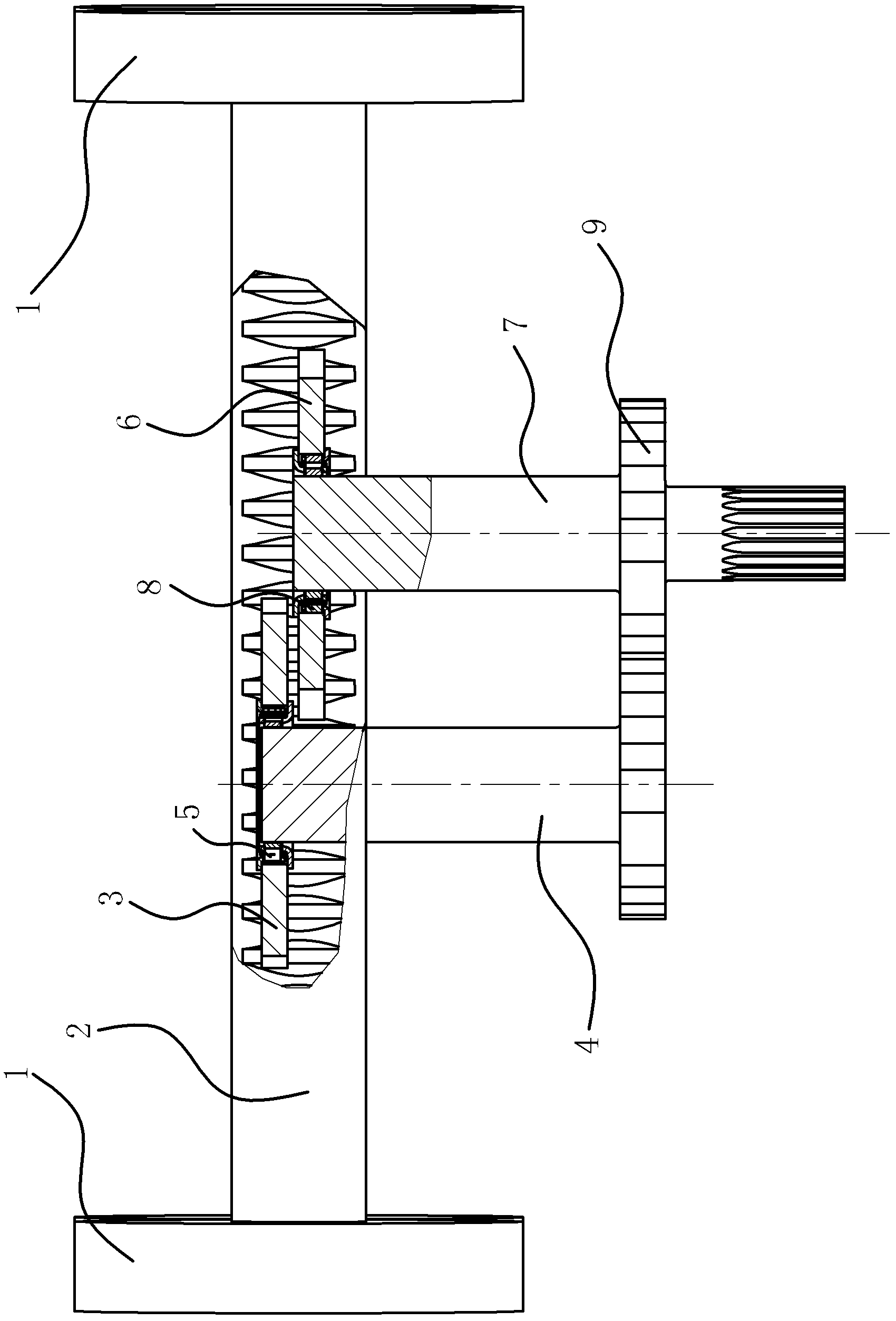

[0035] Such as Figure 1 to Figure 6 As shown, this internal combustion engine without crankshaft and connecting rod includes components such as a cylinder block 10, a rack 2, an output shaft 7, a piston 1 and a gear transmission mechanism.

[0036]Specifically, there are two racks 2, the two racks 2 are parallel and the teeth are opposite to each other. Both ends of each rack 2 are fixedly connected with a piston 1 , so it can be seen that the number of pistons 1 is four. According to the actual situation, the piston 1 is connected with the rack 2 to improve the mechanical strength. The connection between the rack 2 and the piston 1 is located at the center of the end surface and is opposite to the top surface 1e of the piston 1 connected to the same rack 2 .

[0037] There is a combustion chamber in the cylinder 10 that corresponds to the position and direction of movement of the piston 1; therefore, the piston 1 and the rack 2 are positioned on the cylinder 10. When the f...

Embodiment 2

[0052] The structure and principle of this embodiment are basically the same as that of Embodiment 1, except that the gear transmission mechanism includes an input gear 3 meshing with one rack 2 and an input gear meshing with another rack 2 Two 6 and the intermediate gear shaft 4 positioned on the cylinder block 10; between the input gear one 3 and the intermediate gear shaft 4, the one-way clutch one that makes the input gear one 3 only drive the intermediate gear shaft 4 to rotate in one direction 5 are connected; the output shaft 7 is fixedly connected with the transmission gear 9 meshed with the tooth portion of the intermediate gear shaft 4; the input gear two 6 and the output shaft 7 are connected by making the input gear two 6 only along the relative Drive the one-way clutch two 8 that output shaft 7 rotates in the opposite direction of input gear one 3 driving intermediate gear shaft 4 rotation direction to link to each other.

[0053] Simply put, the input gear one 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com