Elastic alignment pipe component for perforation of oil and gas wells

A technology of oil and gas wells and elastic parts, applied in the field of alignment pipes, can solve the problems of poor control of system cumulative errors, achieve good alignment, ensure alignment and righting effects, and ensure smooth explosion transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following examples further illustrate the invention, but do not limit it in any way.

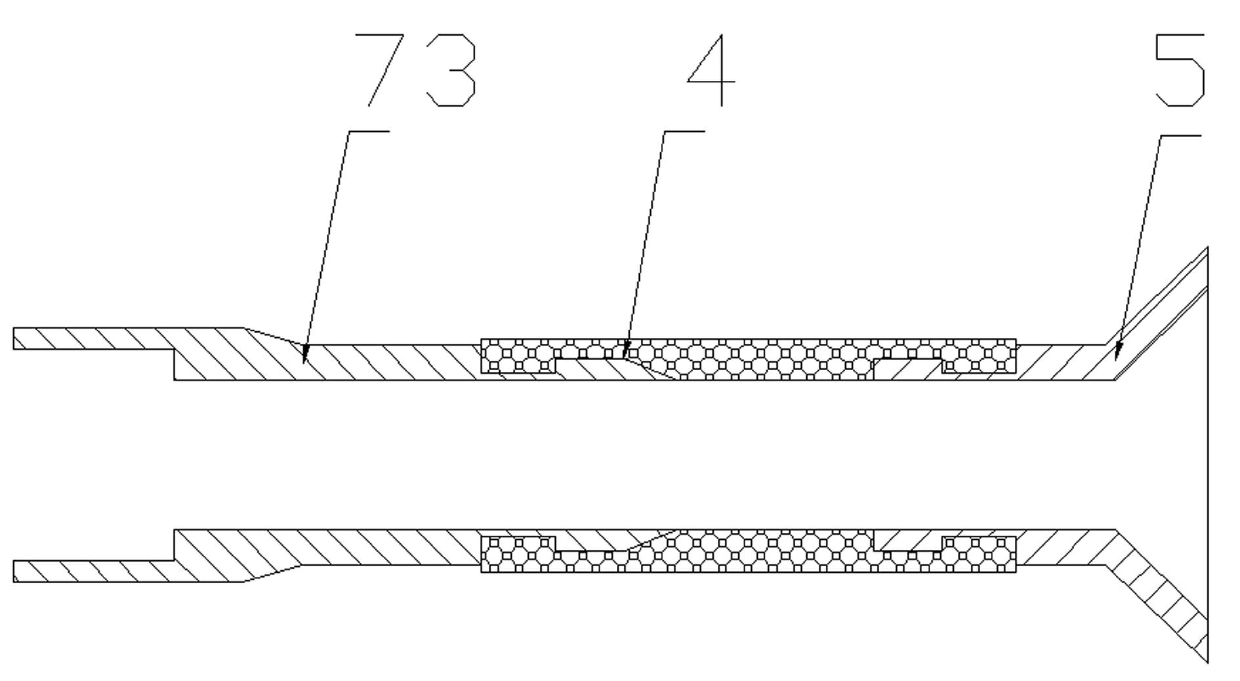

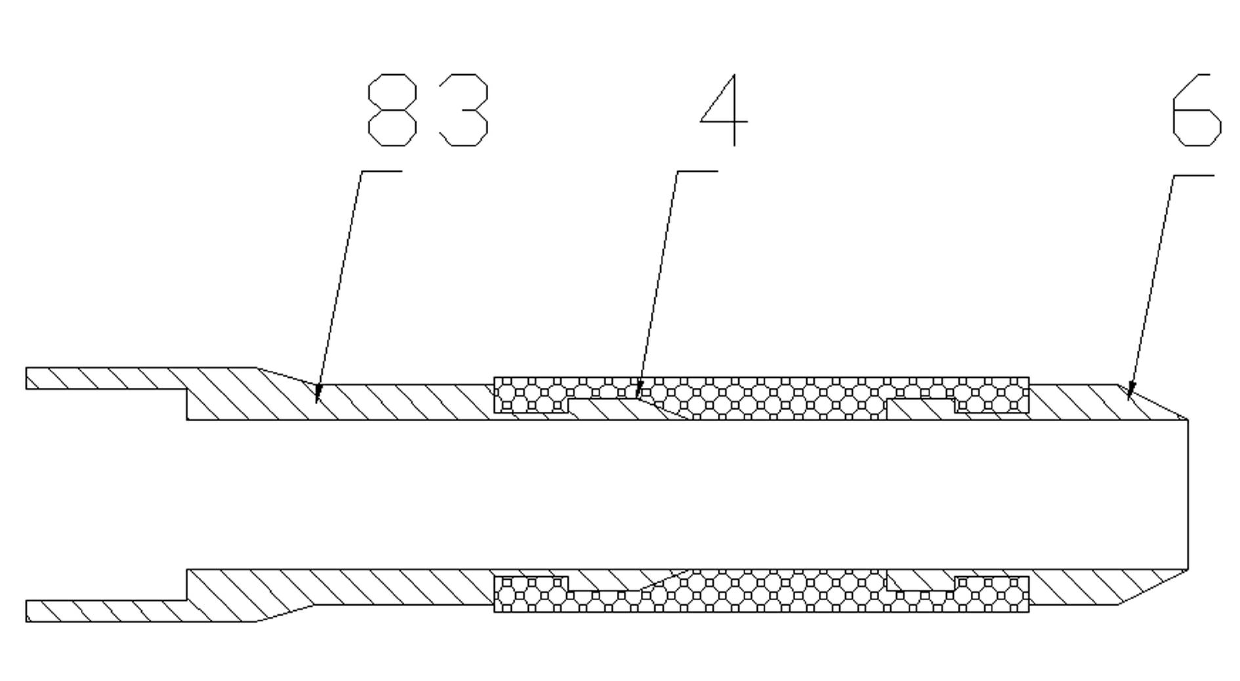

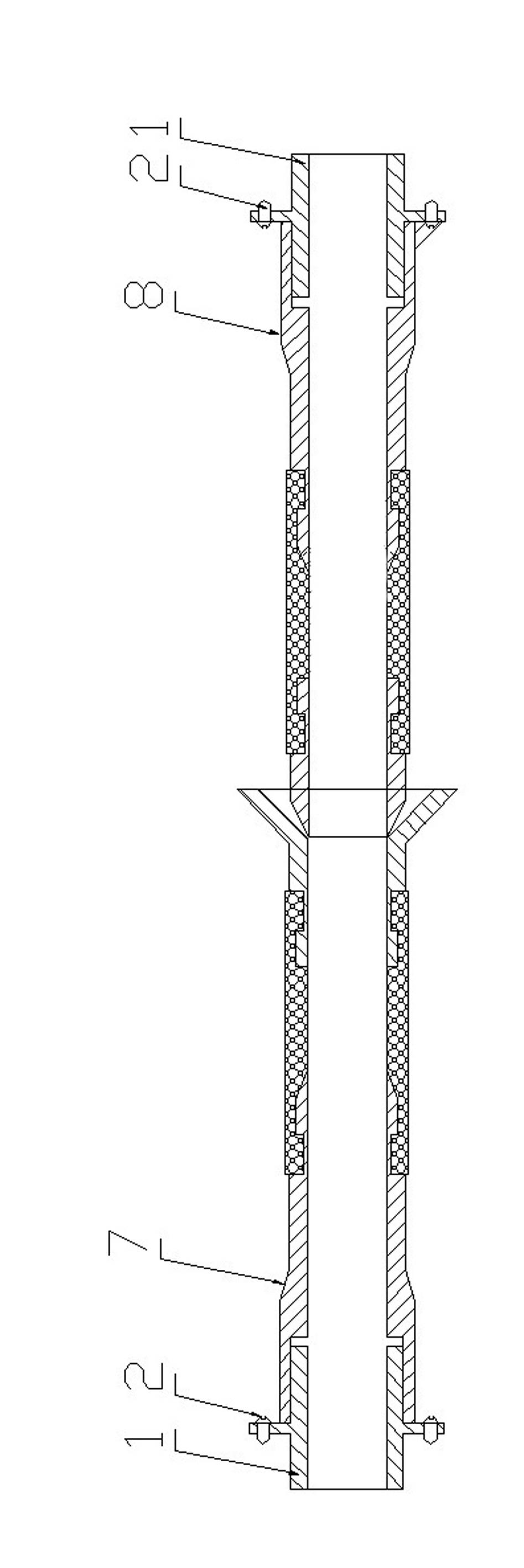

[0026] An elastic alignment tube assembly for oil and gas well perforation is formed by inserting a first alignment tube 7 and a second alignment tube 8, and the inner diameters of the first alignment tube 7 and the second alignment tube 8 are the same , the first alignment tube 7 includes a first alignment tube seat 73 and an alignment tube joint 5, the second alignment tube 8 includes a second alignment tube seat 83 and an alignment tube plug 6, and the pair The alignment pipe plug 6 is inserted into the alignment pipe joint 5, the first alignment pipe seat 73 and the alignment pipe joint 5 are connected by the elastic member 4, and the second alignment pipe seat 83 and the alignment pipe plug 6 are connected by the elastic piece 4 is connected.

[0027] The nozzle of the alignment pipe joint 5 is in the shape of a bell mouth.

[0028] The end of the alignment pipe plug 6 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com