Control method of Casson model drilling fluid rheological parameters

A rheological parameter and control method technology, which is applied in earthwork drilling, wellbore flushing, wellbore/well components, etc., can solve problems such as complicated methods, unsuitable on-site real-time operation, and large amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

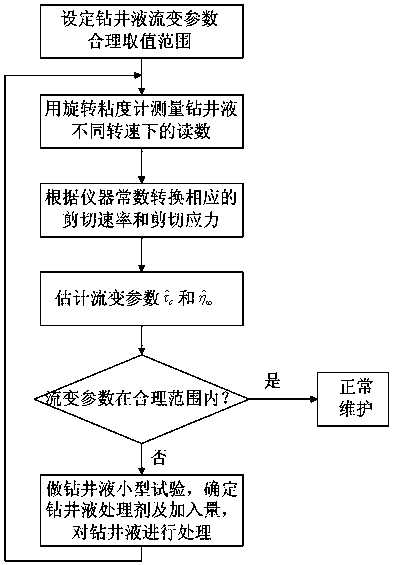

[0036] The control method of rheological parameters of drilling fluid in Carson mode, the specific steps are as follows:

[0037] Step 1: Determine the drilling fluid Casson yield value τ according to the borehole size, borehole expansion ratio, annular space, solid particles and mud pump displacement c and Carson viscosity η ∞ reasonable range of values;

[0038] Step 2: Collect drilling fluid samples in the mud tank in front of the vibrating screen, measure the readings θ at N different speeds Φ with a rotational viscometer, and record the N different speeds Φ and the corresponding readings θ;

[0039] Step 3: Convert the different rotational speeds Φ and corresponding readings θ obtained in step 2 into corresponding shear rate γ and shear stress τ according to the instrument constant of the rotational viscometer;

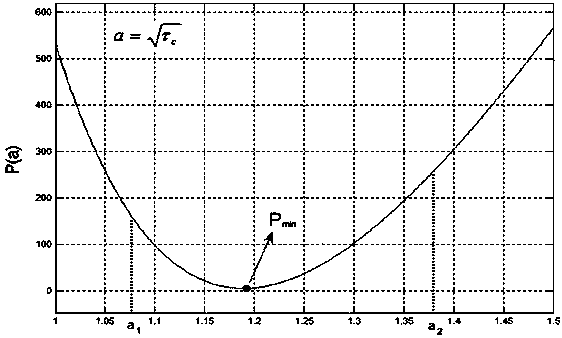

[0040] Step 4: Based on the data in Step 3, estimate the Carson yield value τ c and Carson viscosity number η ∞ , to get the Carson yield estimate and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com