Marsh gas collection and storage floater and marsh gas compression conveyor using same

A biogas collection and biogas technology, applied in the field of biogas, can solve the problems of scooping biogas liquid, inconvenient feeding, complicated manufacturing process, long working hours, etc., and achieve the effect of convenient and economical transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

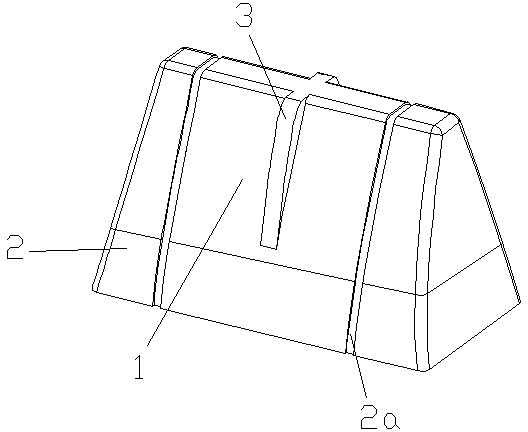

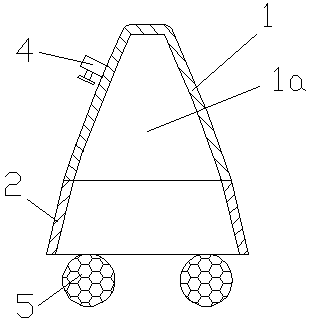

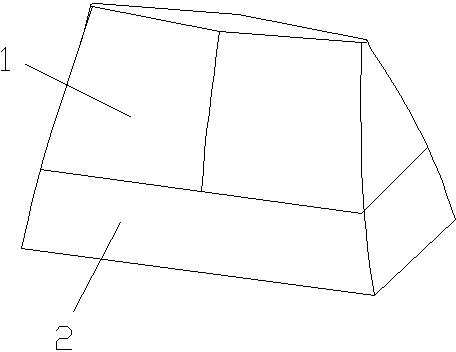

[0029] Embodiment 1: As shown in the figure, the biogas collection and storage buoyant device of this embodiment includes a cover body 1, which is provided with a biogas collection and storage chamber 1a that gradually shrinks from the mouth to the top, and the inner and outer walls of the cover body 1 The shapes are the same, the ratio of the length of the top of the cover to the length of the mouth of the cover is 0.997, and the ratio of the width of the top of the cover to the width of the mouth of the cover is 0.15. Of course, in specific implementation, the ratio of the length of the top of the lid to the length of the mouth of the lid can be other values in the range of 0.65-0.997, and the ratio of the width of the top of the lid to the width of the mouth of the lid can be other values in the range of 0.15-0.4. The shape of the cover body 1 with values within this range presents an obvious upper-smaller-lower-large shape, which is conducive to making the biogas in t...

Embodiment 2

[0037] Embodiment 2. The difference between the methane storage buoyant device of this embodiment and Embodiment 1 is that the ratio of the length of the top of the cover to the length of the mouth of the cover is 0.65, and the ratio of the width of the top of the cover to the width of the mouth of the cover is 0.4; Other structures of the methane storage buoyant are the same as those in Embodiment 1.

Embodiment 3

[0038] Embodiment 3, the difference between the biogas storage and storage lifter of this embodiment and Embodiment 1 is that the ratio of the length of the top of the cover to the length of the mouth of the cover is 0.75, and the ratio of the width of the top of the cover to the width of the mouth of the cover is 0.25; Other structures of the methane storage buoyant are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com