Sorting and conveying unit with improved outlet

A technology for conveying devices and outlet troughs, applied to conveyors, conveyor objects, vibrating conveyors, etc., can solve problems such as storage container troubles and accidents, and achieve the effects of simplified structure, simple cost, and simplified overall process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

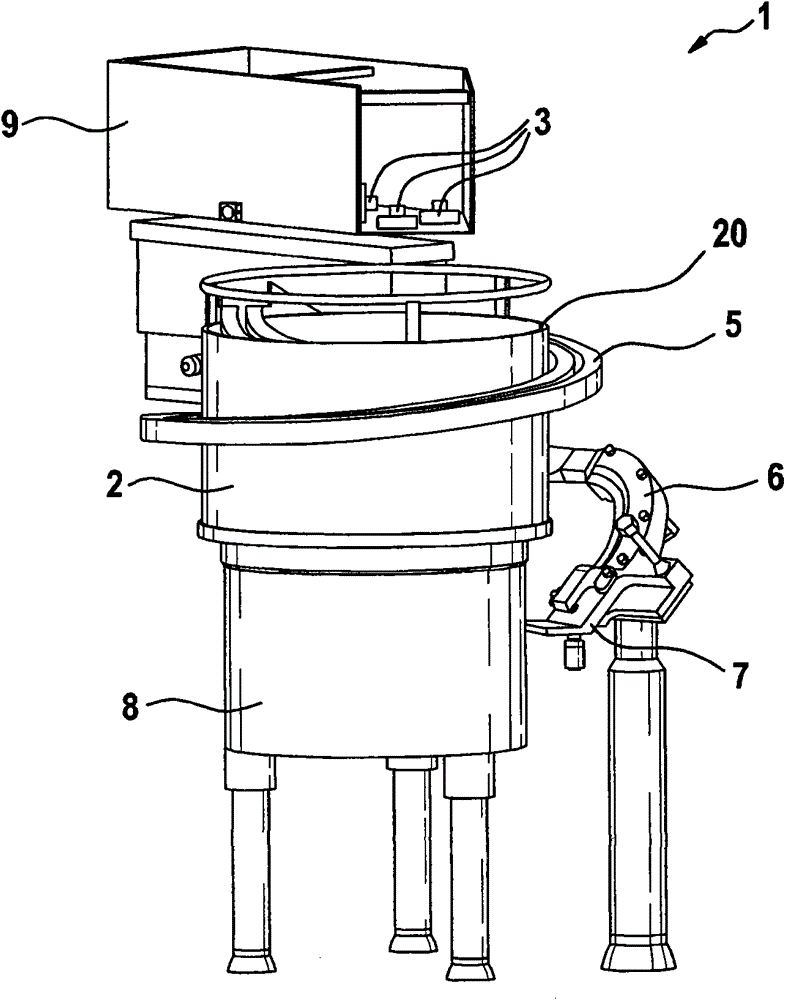

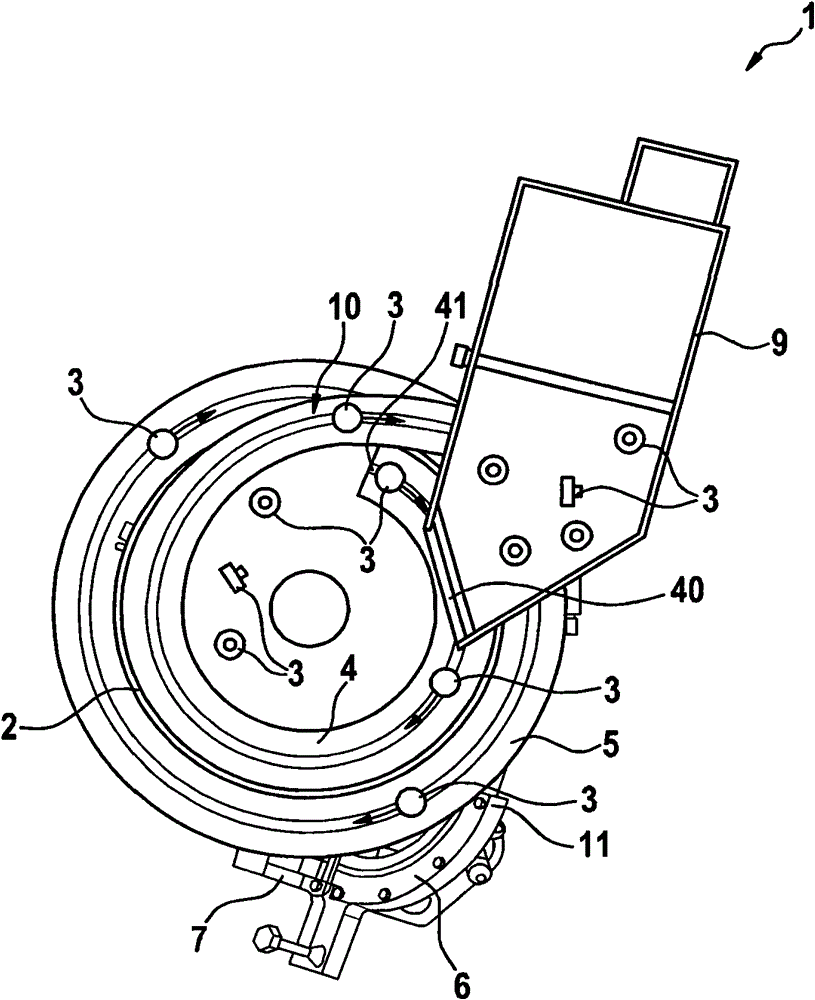

[0016] Refer below figure 1 and 2 The sorting and conveying device 1 according to a preferred embodiment of the present invention is described in detail.

[0017] especially from figure 1 As can be seen in the figure, the sorting and conveying device 1 comprises a sorting tank 2 in which the closures 3 are arranged in a random manner. The sorting tank 2 comprises an inlet slot 4 in which the cover 3 is oriented. Furthermore, said sorting tank 2 comprises an outlet chute 5 starting at an upper opening 20 of said sorting tank 2 . The inlet groove 4 here transitions directly at the upper opening 20 in the transition region 10 into the outlet groove 5 .

[0018] The sorting and conveying device 1 also includes a storage container 9 for storing unordered closures and which is arranged above the sorting tank 2 . especially from figure 2 As can be seen in FIG. 2 , the storage container 9 is arranged above the sorting tank 2 in such a way that the outlet opening 40 protrudes in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com