Printing method capable of quickly aligning glass substrate with screen

A technology of glass substrate and alignment printing, which is applied in printing, printing devices, etc., can solve the problem of slow alignment and achieve the effect of fast alignment speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

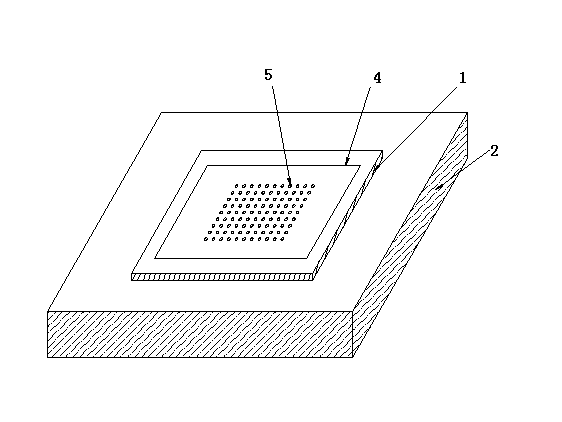

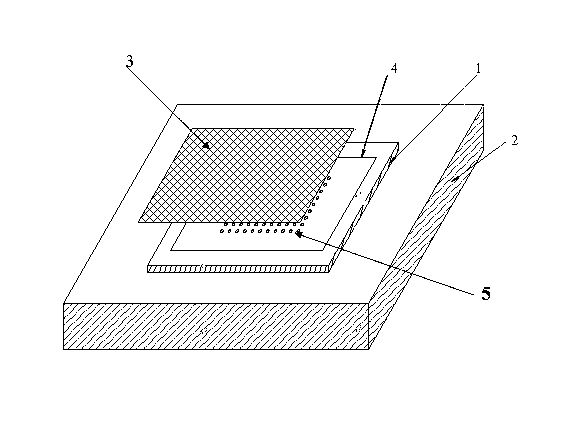

[0021] Such as figure 1 , 2 , 3 shown.

[0022] A method for rapid alignment printing of a glass substrate and a screen, comprising the following steps:

[0023] a. Slurry preparation, put the slurry to be printed into a clean mixing box, stir, and defoam to obtain the slurry for use;

[0024] b. Clean the glass substrate 1 with a washing machine;

[0025] c. Set the printing parameters of the screen printing machine;

[0026] d. Use an oil-based pen to draw the frame figure 4 on the central part of the table top 2 of the screen printing machine, so that the drawn frame figure 4 matches the frame of the screen figure 3 and is slightly smaller; the drawn frame figure 4 is not only clear but also difficult be wiped away; as figure 1 , in order that the frame graphics 4 will not affect the official printing, the raised height of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com