Polishing powder collecting device for processing rice

A collection device and rice processing technology, applied in applications, grain processing, agriculture, etc., can solve the problems of high moisture content of polishing powder, unsuitable for storage and processing, etc., and achieve the effects of prolonged hand feeling, reduced downtime cleaning time, and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

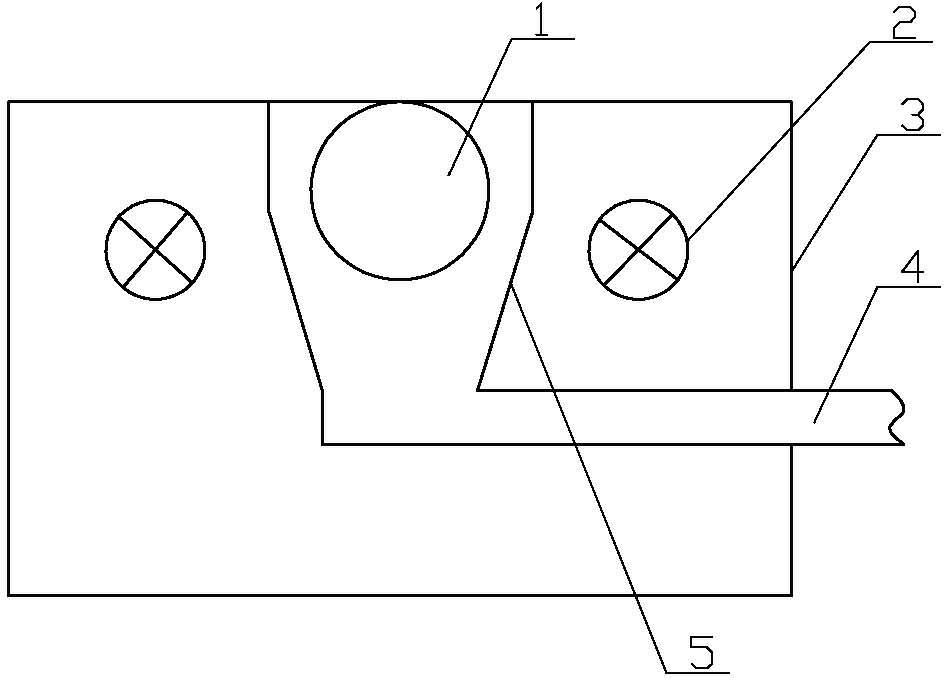

[0011] Depend on figure 1 It can be seen that when the rough rice is polished with a polishing machine, the polishing powder (rice bran powder) produced by it is collected by the collecting bucket 5, the air duct 4, the Shacron, and the air locker. Since the polishing powder contains a certain amount of water, During transportation, adhesion and clogging often occur in pipelines, shackles and air locks, which need to be cleaned regularly. Moreover, due to the high moisture content of polishing powder, it is not suitable for storage and treatment.

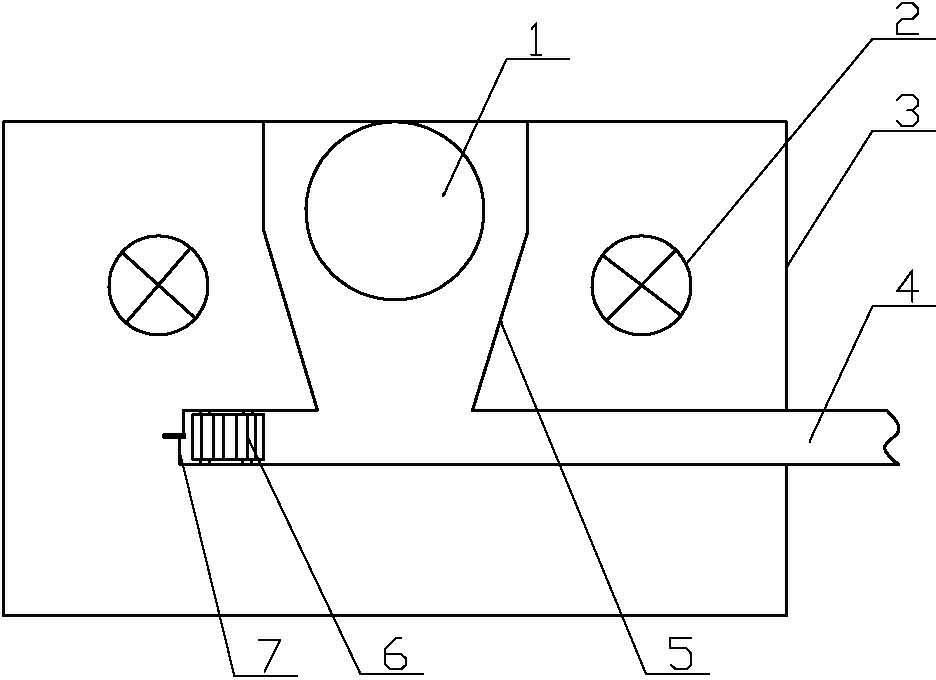

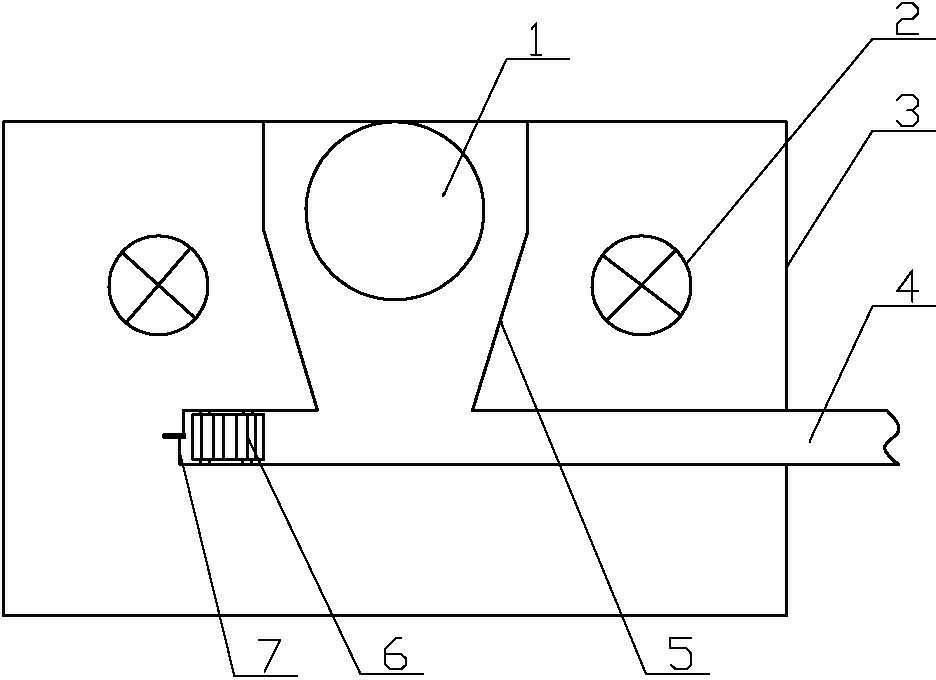

[0012] Depend on figure 2 It can be seen that a polishing powder collecting device for rice processing comprises a polishing machine body 3, a polishing machine 1 is arranged in the polishing machine body 3, a collecting bucket 5 is provided at the bottom of the polishing machine 1, and a collection bucket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com