Filling device of suction nanometer fiber solid phase extraction column and application thereof

A solid-phase extraction column and nanofiber technology, applied in the field of separation, can solve the problems of inconvenient and unstable filling process, and the effect of filling and filling of solid-phase extraction column is difficult, so as to achieve easy automation, reduce filling time, and realize batch processing. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

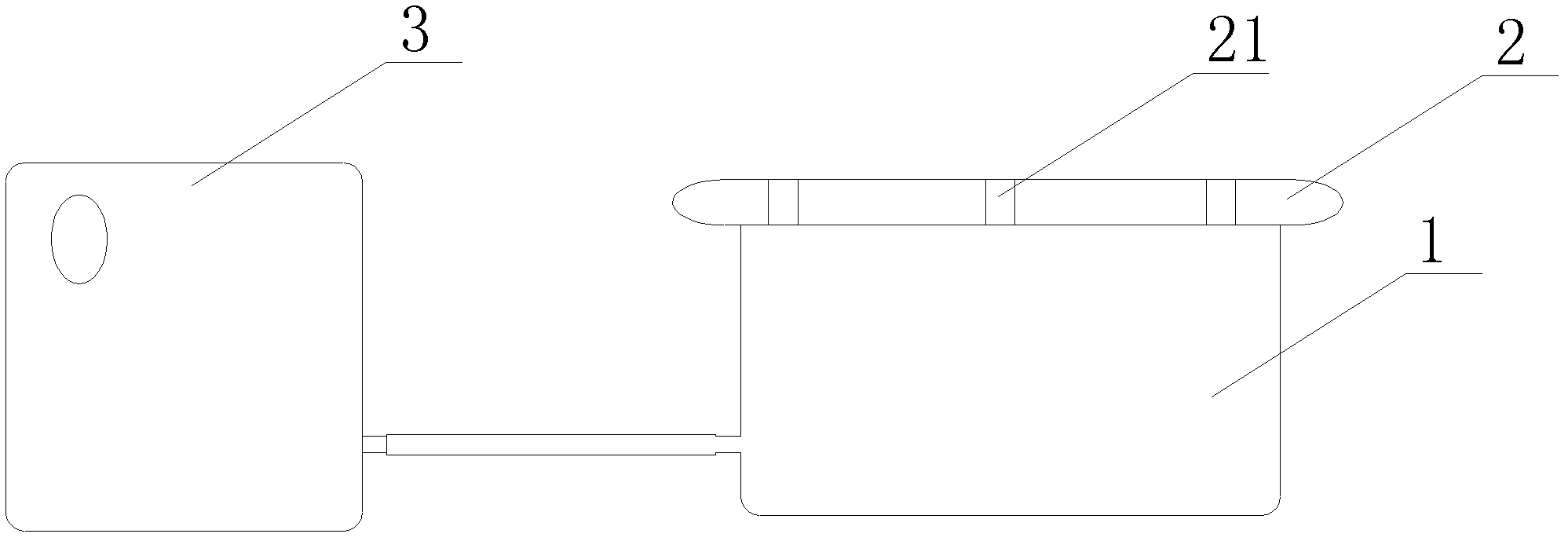

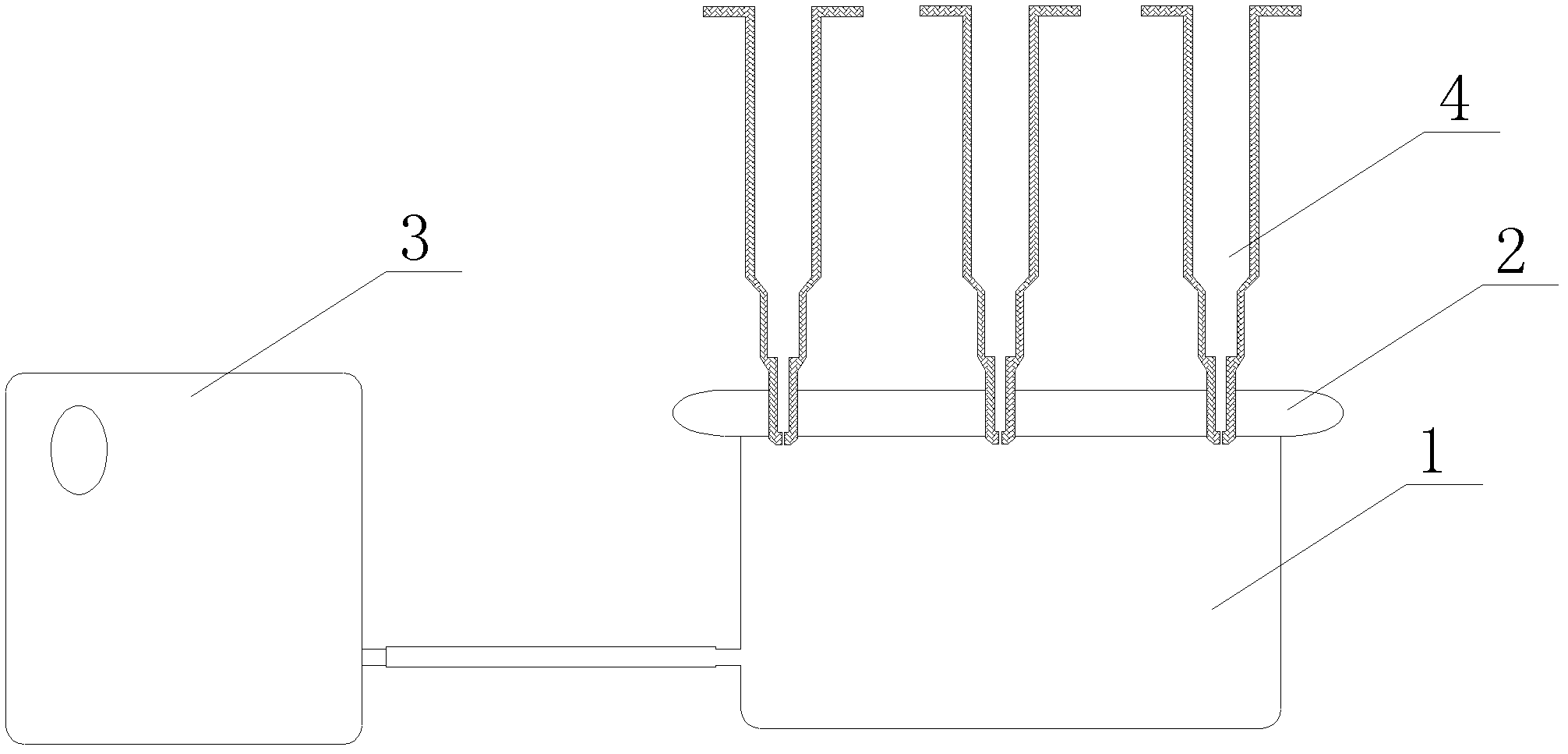

[0025] like figure 1 As shown, the suction nanofiber solid-phase extraction column filling device includes a pressure tank 1 that is sealed, and the notch of the pressure tank 1 is provided with a sealing block 2 for fixing the solid-phase extraction column 4, and a negative pressure tank 1 is arranged outside the pressure tank 1. Pressure extraction device 3, the negative pressure extraction device 3 communicates with the pressure tank 1 for negative pressure suction.

[0026] The sealing block 2 is provided with several fixing holes 21, the solid phase extraction column 4 is fixed with the fixing holes 21, and the extraction channel in the solid phase extraction column 4 communicates with the pressure tank. The negative pressure extraction device 3 is an air pump.

[0027] like figure 2 As shown, when filling the suction nanofiber SPE column, first fix the SPE column on the suction nanofiber SPE column filling device; immerse the nanofibers in the filling liquid; then fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com