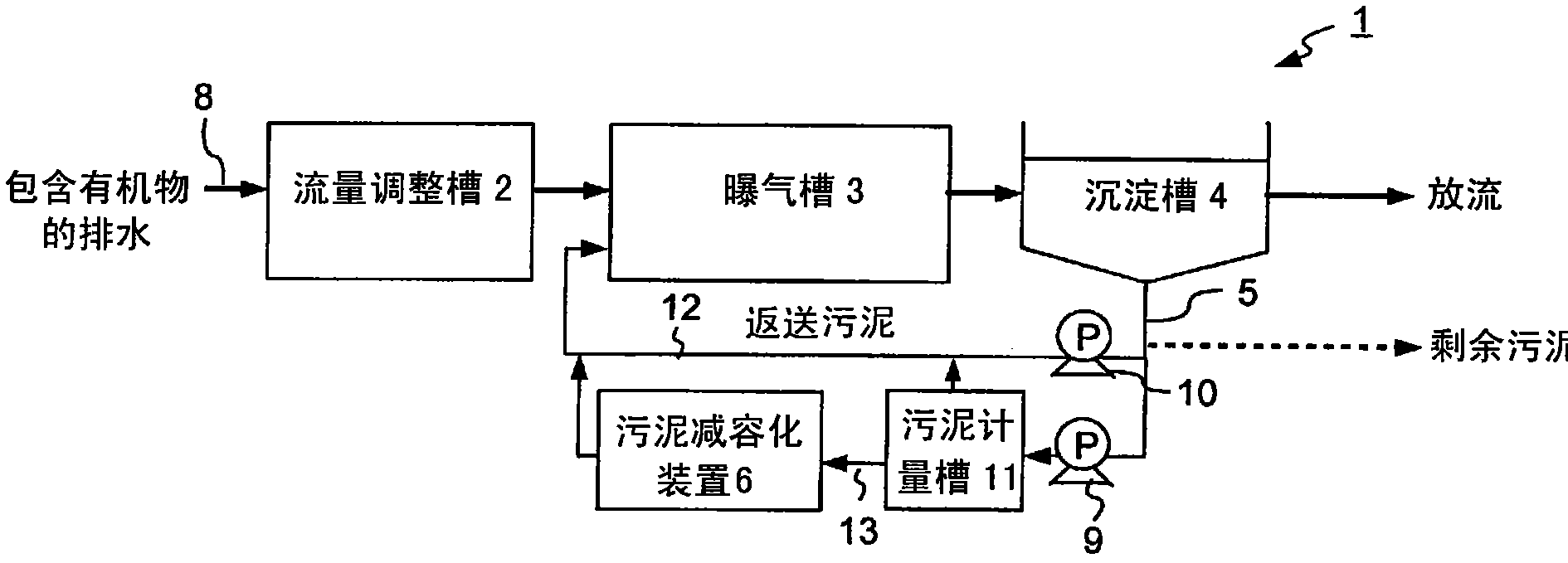

Method and apparatus for reducing sludge amount

A technology of sludge and activated sludge, which is applied in the direction of sludge treatment, oxidation treatment sludge, chemical instruments and methods, etc., can solve the problems of reduced bactericidal power, etc., and achieve the goals of reducing pH value, increasing available chlorine concentration, and load suppression Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

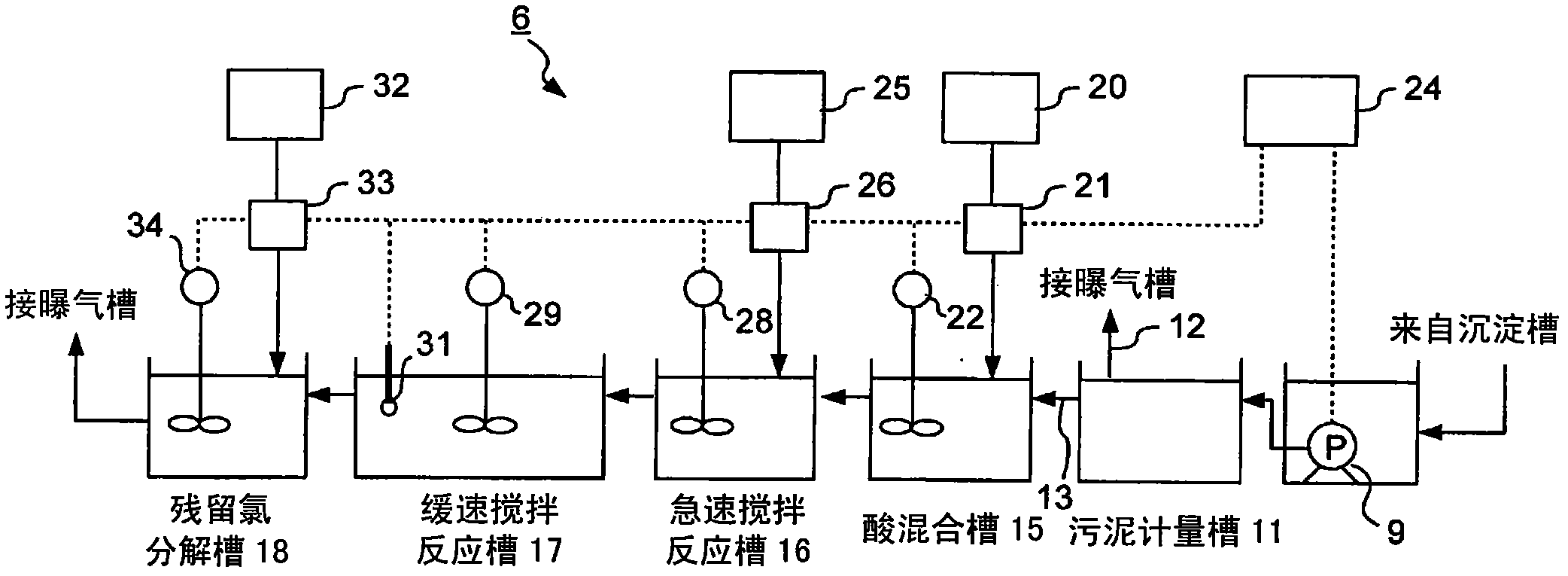

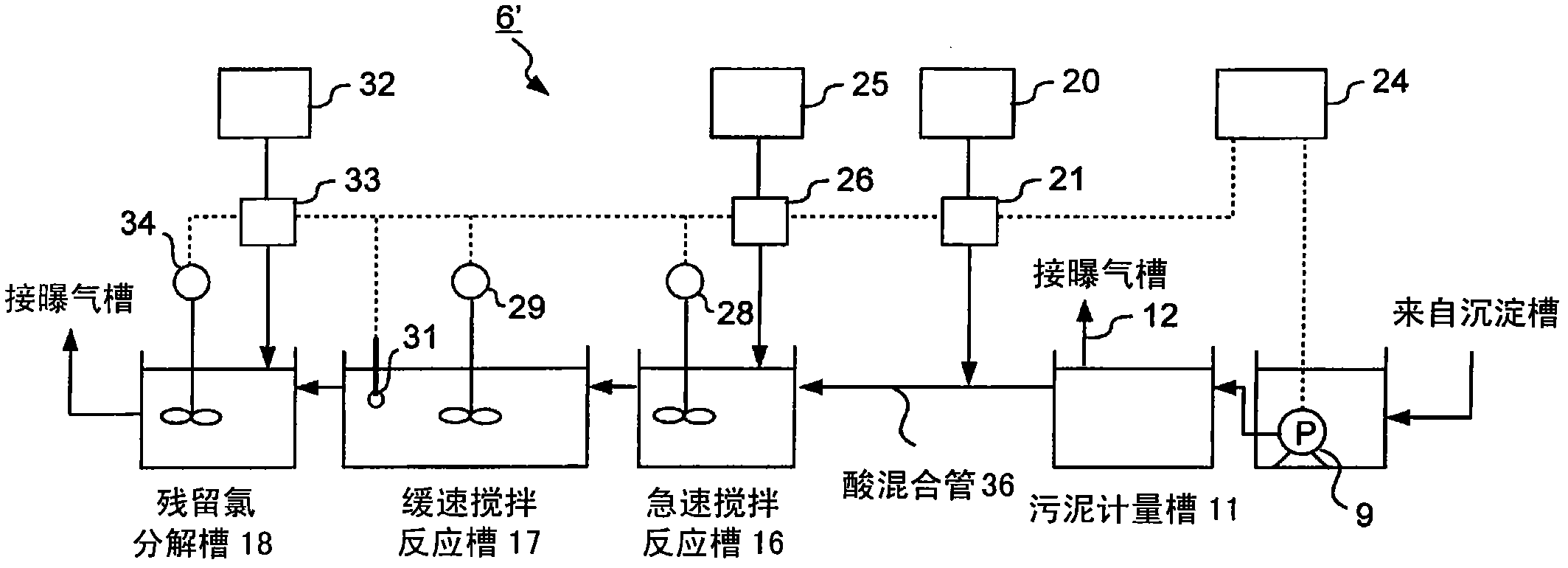

Method used

Image

Examples

Embodiment 1

[0061] Whether the aqueous solution formed by premixing dilute hydrochloric acid and sodium hypochlorite aqueous solution, that is, the biological mother solution (biomaster) is injected into the sludge, and the dilute hydrochloric acid and sodium hypochlorite aqueous solution are respectively injected, and whether the effect of matrixing of the sludge is confirmed. Experiments with differences.

[0062] Biological mother liquor is prepared according to the following method, the method is: a specified amount of 8.5% dilute hydrochloric acid is mixed with a specified amount of 12% sodium hypochlorite aqueous solution, and then diluted with water, the pH value is 6, and the concentration of available chlorine is 4000mg / L.

[0063] Add the activated sludge with a sludge concentration of 15300mg / L to the four containers A1, A2, A3, and A4 according to the specified amount. Next, into the sludge in the container A1 and the container A2, the biological mother liquors whose availab...

Embodiment 2

[0067] For the case of injecting biological mother liquid into the sludge, and the corresponding occasion of injecting dilute hydrochloric acid and sodium hypochlorite aqueous solution respectively, conduct a batch test of treating raw water collected from the sewer to investigate whether the sludge reduction rate has an effect Experiment with differences.

[0068] Equipped with 3 aeration tanks ×1, ×2, ×3, add the same amount of activated sludge respectively, and add raw water taken from the sewer according to the method of 180L respectively. After performing aeration in each of the aeration tanks ×1, ×2, and ×3 for 21 hours, the aeration was stopped, and the sludge was allowed to settle. After settling, the supernatants were removed from the aeration tanks ×1, ×2, ×3, ie, the water was not treated, leaving only 50 L of sludge in each tank. Take out 10L of sludge from the aeration tank × 2, take it into the container Y2, add the biological mother solution with an available c...

Embodiment 3

[0072] An experiment was conducted to investigate whether chlorine gas was generated when an aqueous solution of sodium hypochlorite was injected into sludge adjusted to acidity.

[0073] Sludge with a sludge concentration of 17100mg / L was taken into a 500mL beaker, and while being stirred by a stirring device, 0.9mL of 8.5% dilute hydrochloric acid was injected, and the pH value was 3.5. Next, the 12% sodium hypochlorite aqueous solution was titrated 1 mL at a time to confirm whether or not chlorine gas was generated, and the pH value at that time was also measured. The experimental results are given in the table.

[0074] (Table 1)

[0075] Chlorine gas production experiment of high-concentration sludge (SS 17100mg / L added to 500mL, starting pH3.5)

[0076] Titration, mL

[0077] As shown in Table 1, chlorine gas was not generated even when the sodium hypochlorite aqueous solution was injected into the sludge of pH 3.5. In addition, when dilute hydrochloric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com