Plate type heat exchanger for granular solid materials

A granular solid, material plate technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of plate failure, reduce output, unrealistic cleaning operation, etc., and achieve convenient disassembly operation. , The effect of prolonging the service life and avoiding repeated alternating loads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

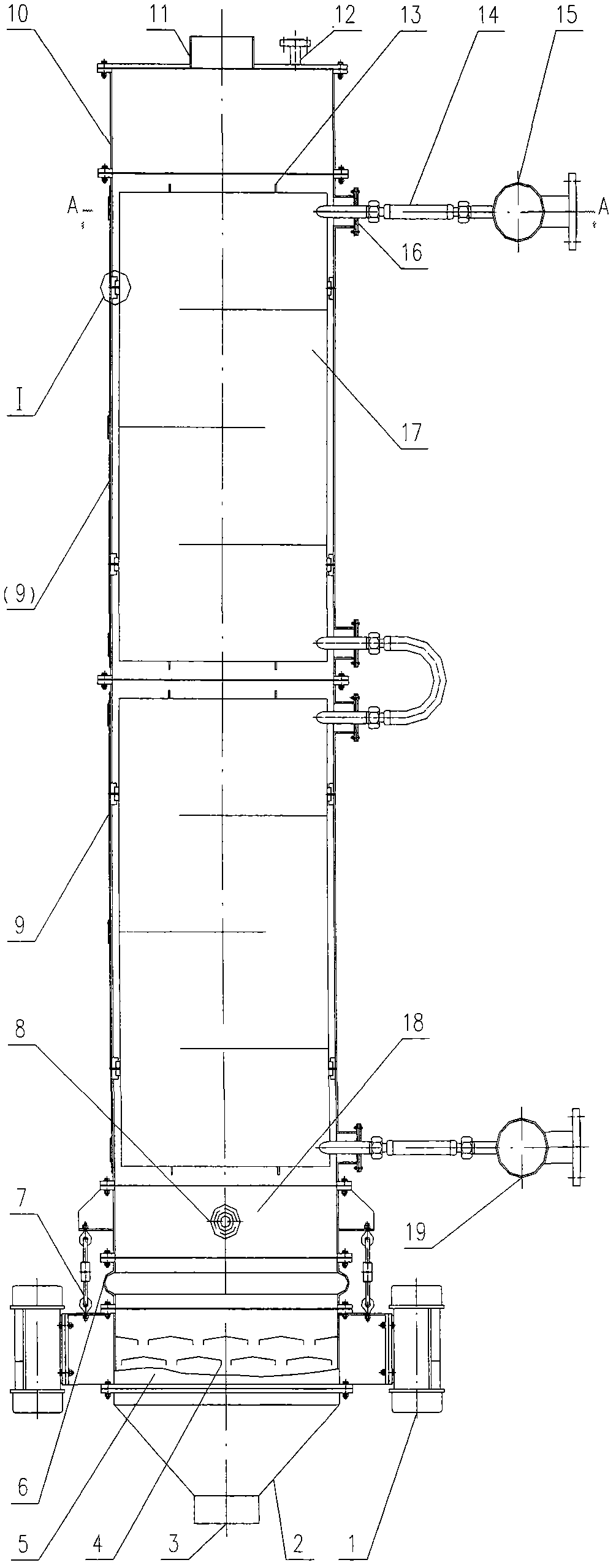

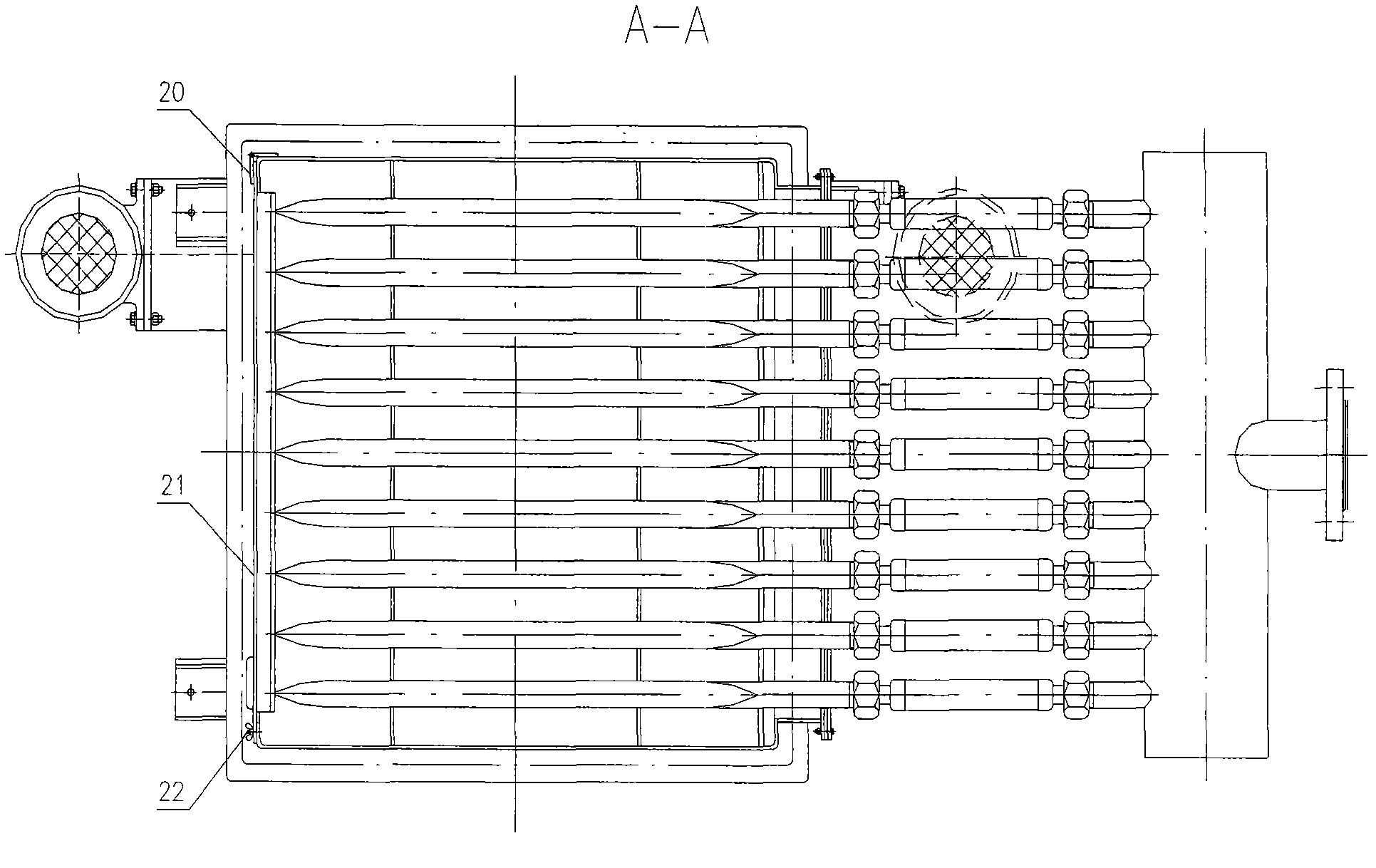

[0025] The whole device of the present invention will be explained below with reference to the embodiment of the accompanying drawings. In this embodiment, the structure of two heat exchange main bodies is adopted.

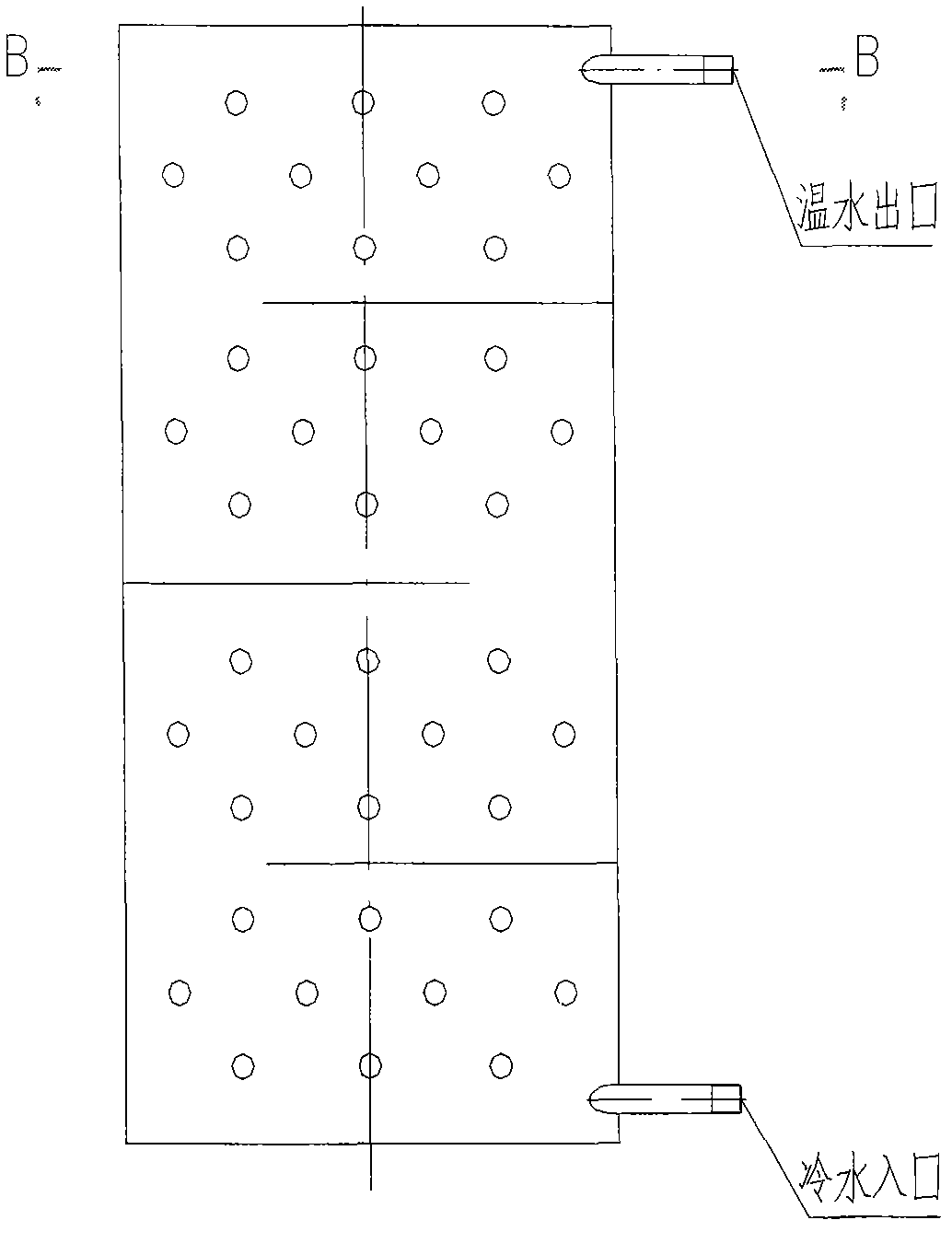

[0026] Depend on figure 1 It can be seen that the powdery solid material plate heat exchanger of the present invention consists of a feed bin 10, an upper and a lower heat exchanger main body 9 assembled in series from top to bottom, and an outlet disposed under the lower heat exchange main body 9. Silo composition. Among them, the heat exchange main body and the feeding bin, as well as the upper and lower heat exchange main bodies are connected and fixed by flanges. The heat exchange main body 9 is fixed with the discharge bin collection box 5 by adjusting the hook chain fixing mechanism 7. The discharge bin collection box 5 is provided with a measuring chamber 18, and the lower end of the silicone bellows 6 is connected to the vibration discharge bin. 2. Conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com