All-welded plate shell type stainless steel condenser and application thereof

A stainless steel, condenser technology, applied in steam/steam condensers, steam engine installations, machines/engines, etc., can solve problems such as unsatisfactory and unattainable, achieve small fluid pressure drop, reduce equipment investment, and heat exchange area. zoom out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention can be further understood through the following examples, but the present invention is not limited in any way.

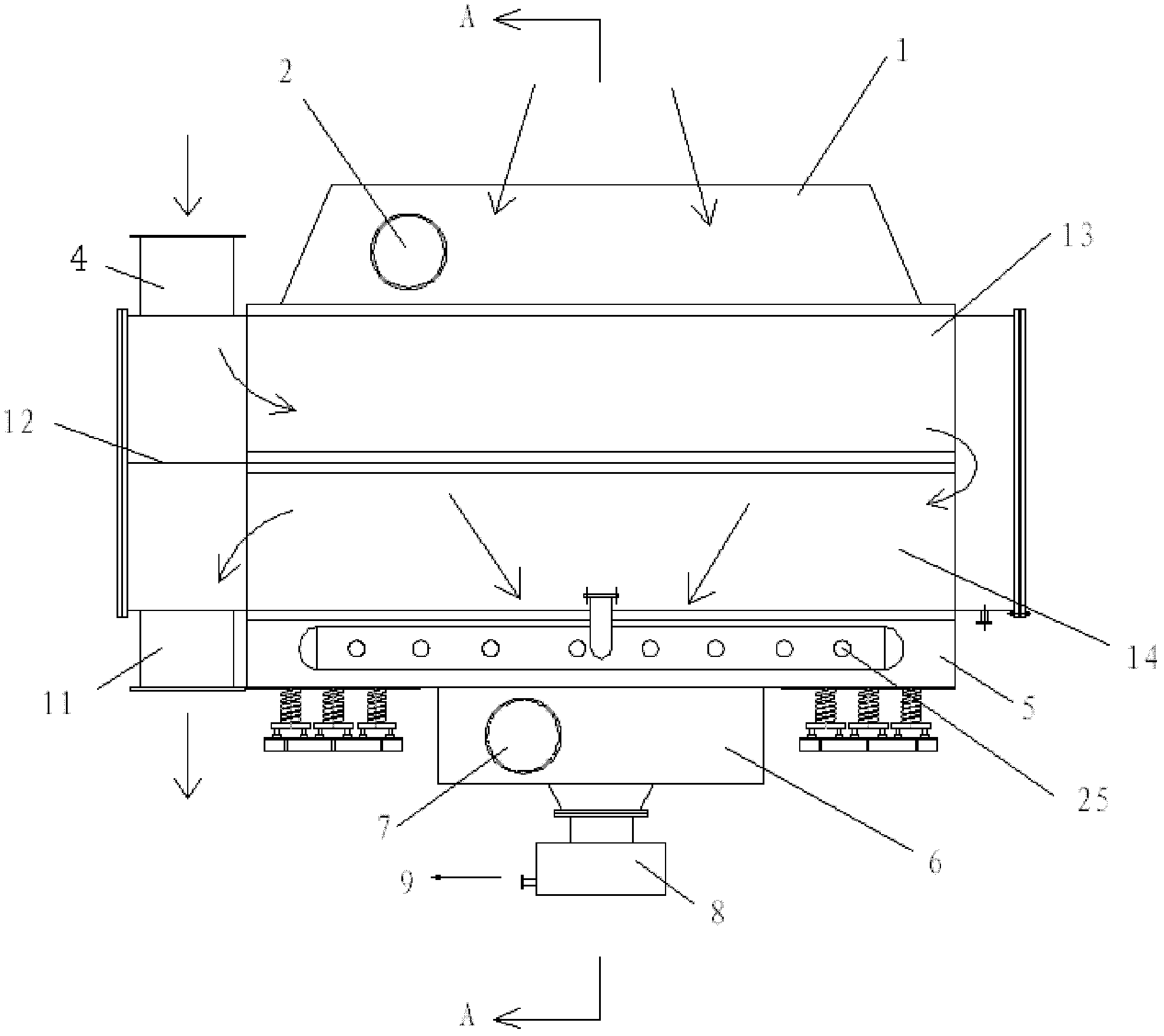

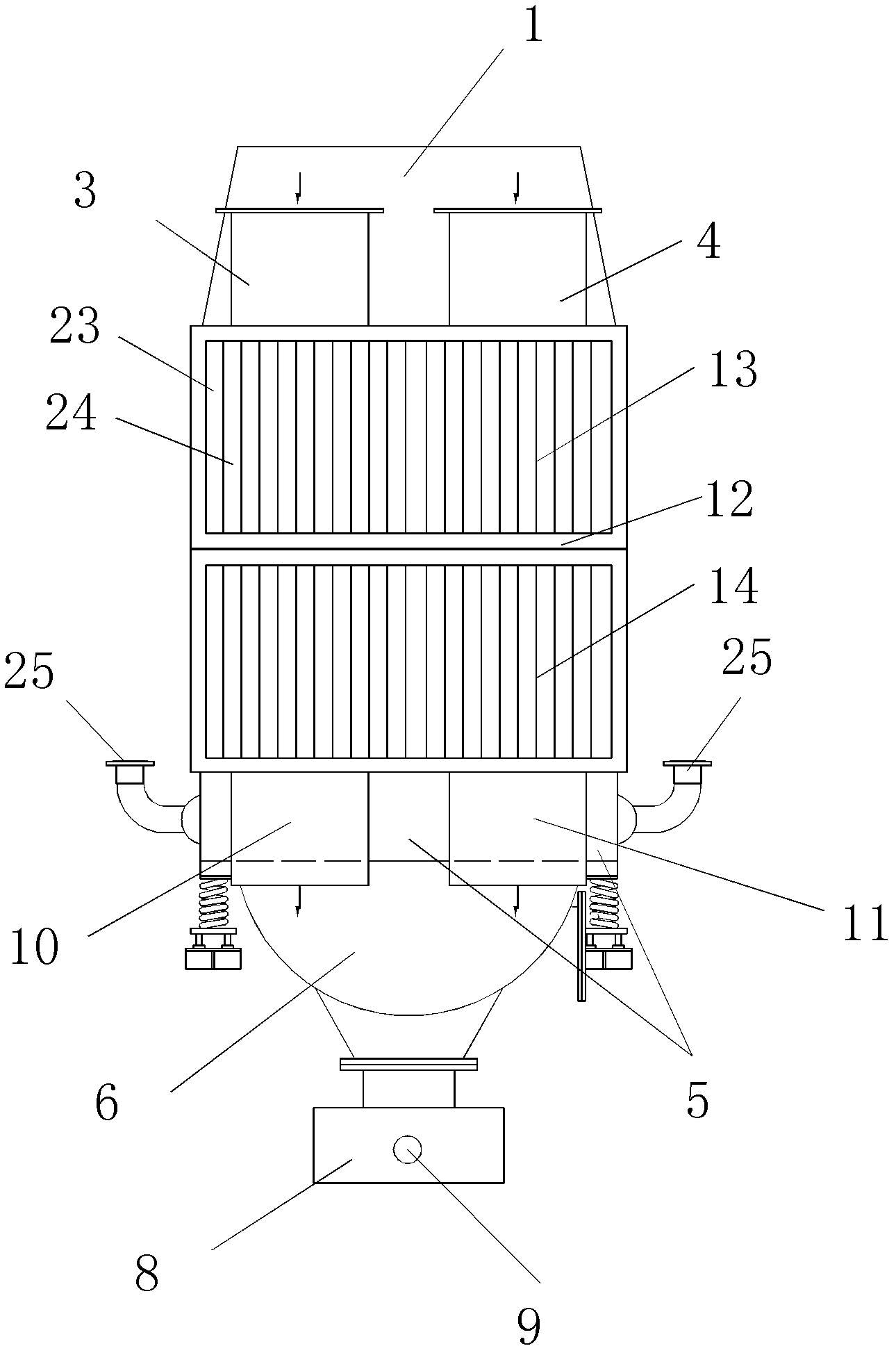

[0029] Such as figure 1 and figure 2 shown.

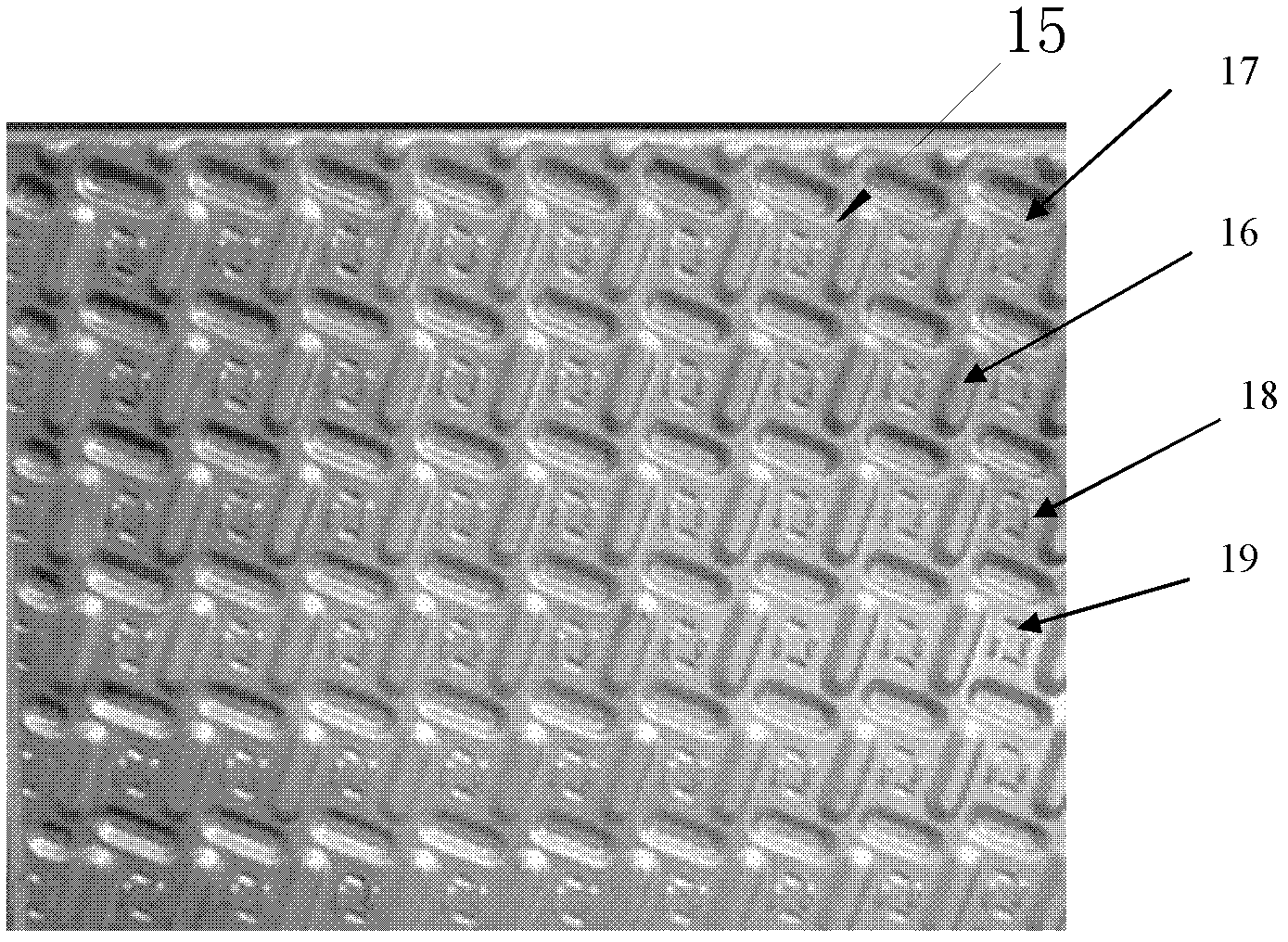

[0030]The overall structure of the all-welded plate and shell stainless steel condenser has a high-vacuum, negative-pressure rectangular box for the steam exhausted part; the top of the rectangular box is equipped with a condenser throat corresponding to the diameter of the exhaust port of the steam turbine exhaust cylinder. Part 1, the left side of the throat 1 is provided with a manhole 2, and the upper left end of the rectangular box is connected to the circulating cooling water inlet 3 and the circulating cooling water inlet 4; the bottom of the rectangular box corresponding to the throat of the condenser is connected to the steam gathering chamber 5 The air outlets 25 are set on both sides of the steam gathering chamber 5; the bottom of the steam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com