Dual-shell small-flow centrifugal pump

A low-flow, double-shell technology, used in special fluid pumps, pumps, components of pumping devices for elastic fluids, etc. , easy sticking and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

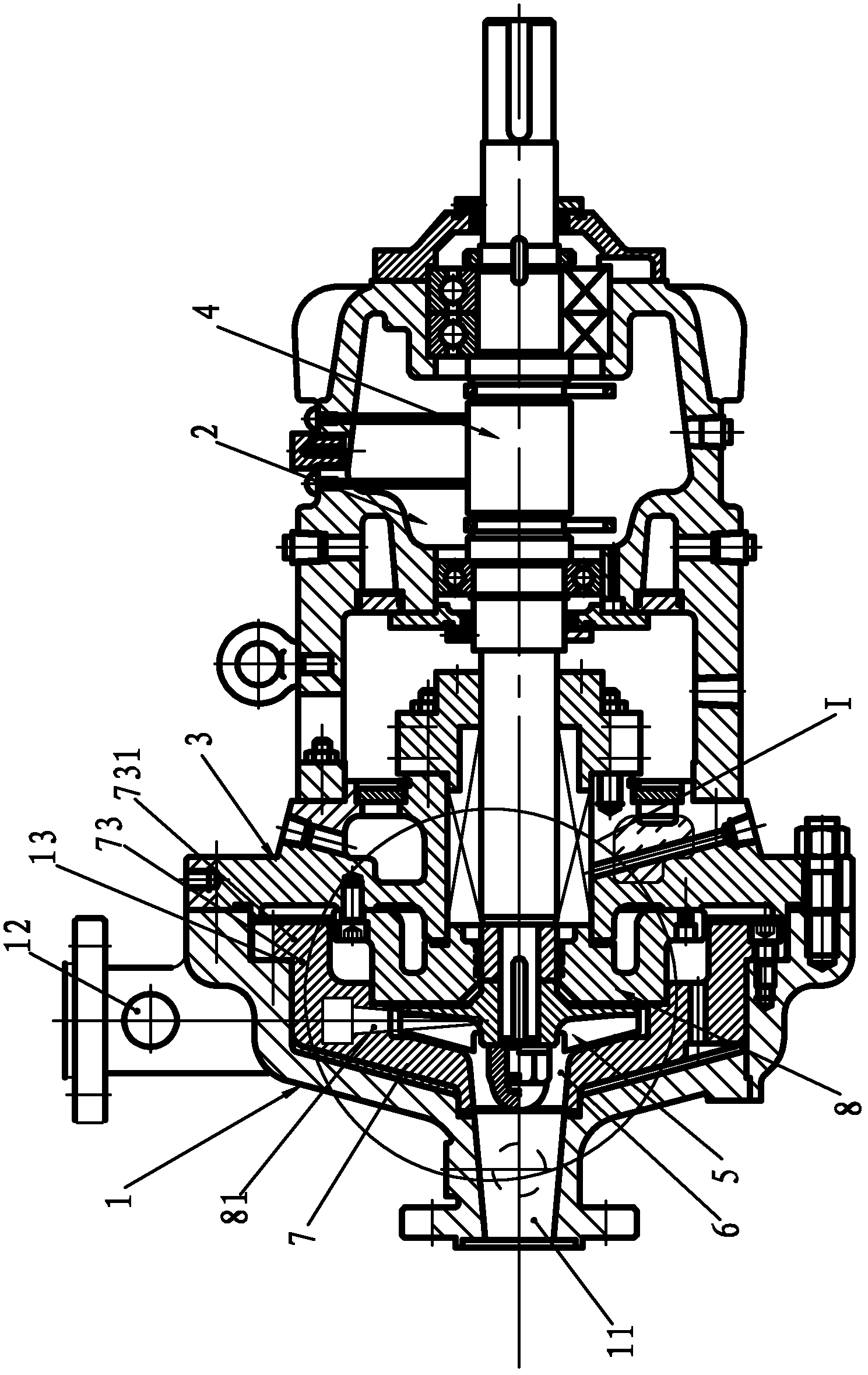

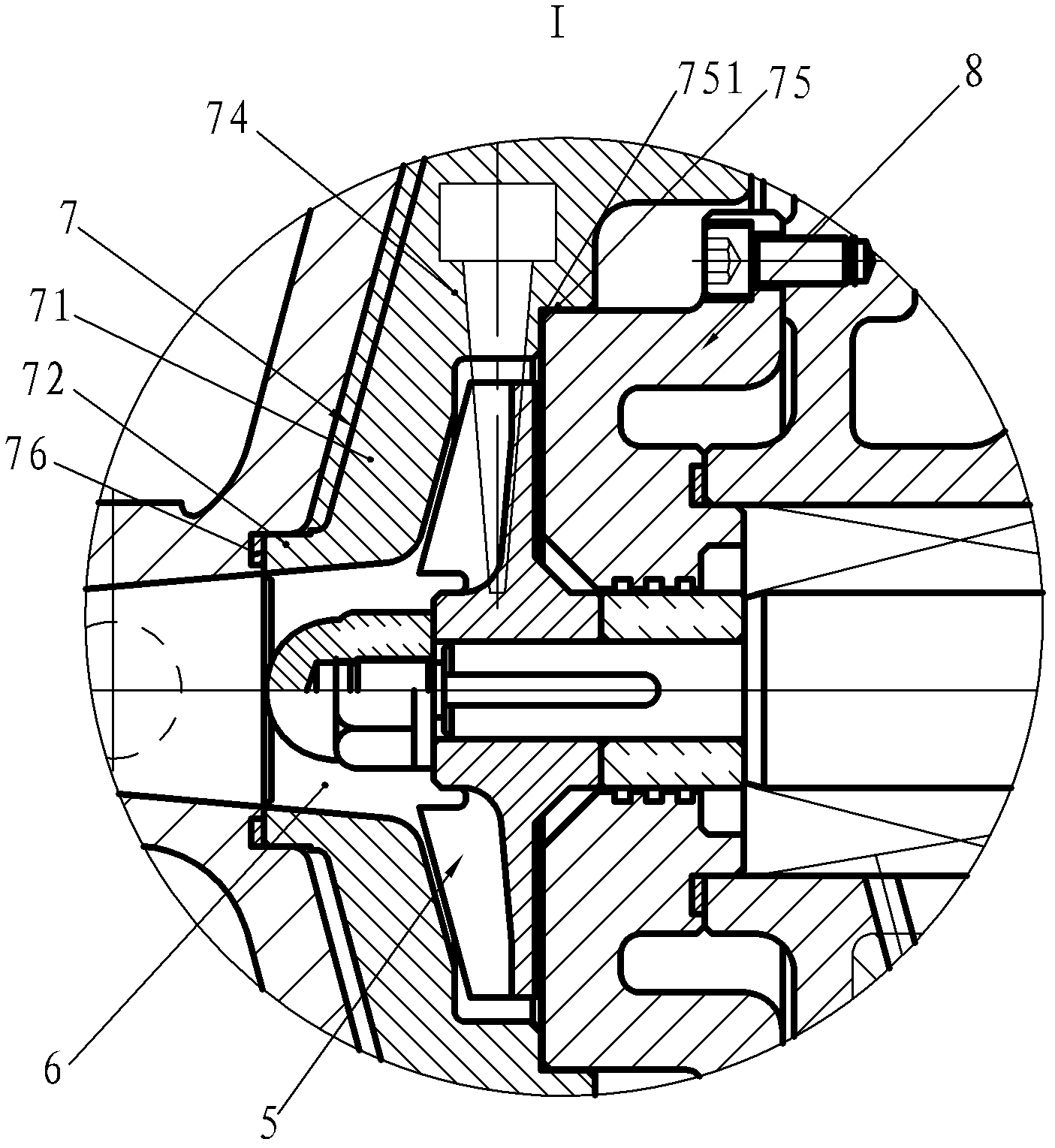

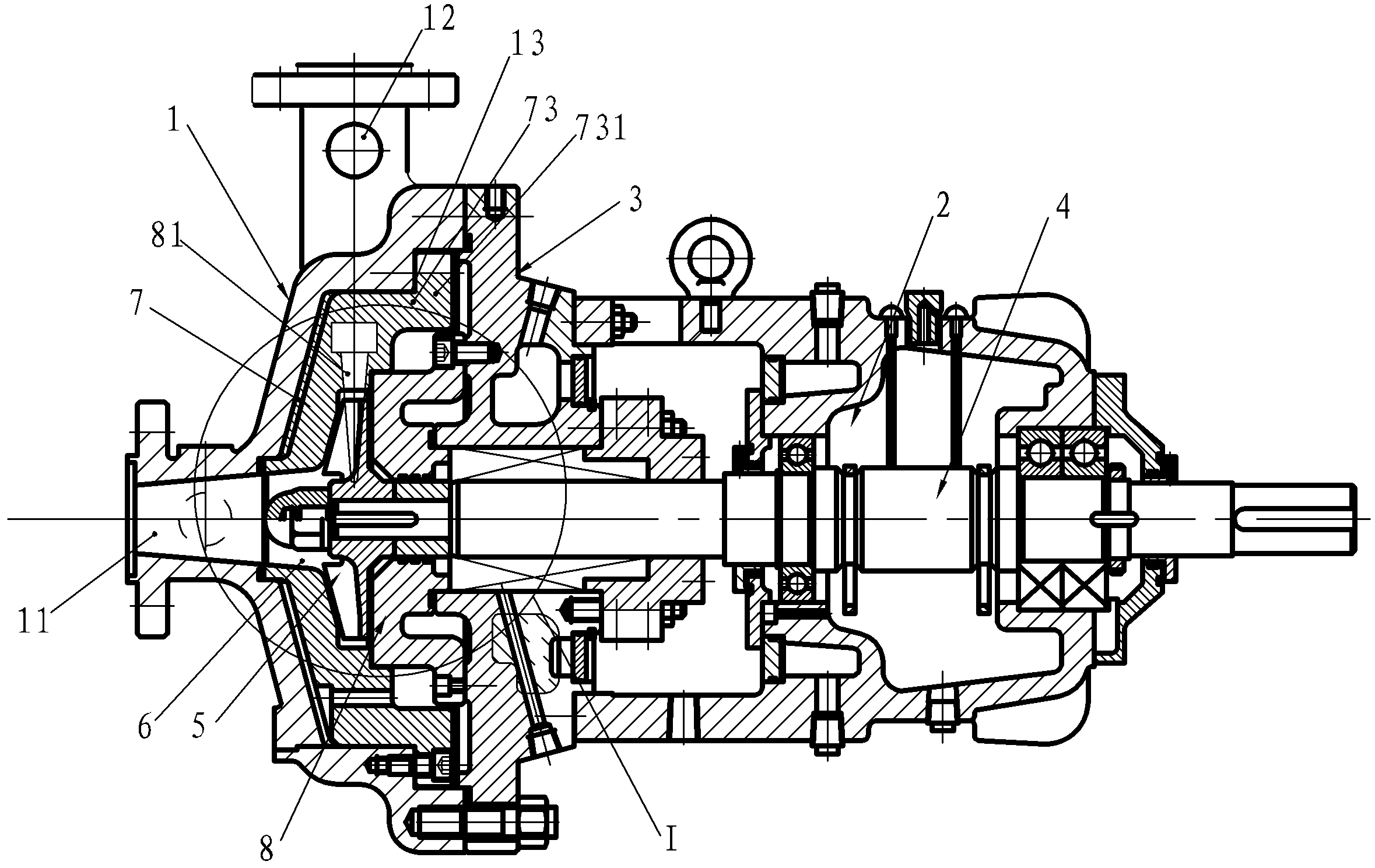

[0013] Such as figure 1 , figure 2 A double-casing small-flow centrifugal pump shown includes a pump body 1,

[0014] The shaft seal device 2, the pump cover 3, the rotating shaft 4 and the impeller 5 are arranged between the pump body 1 and the shaft seal device 2, a flow channel 6 is provided between the pump body 1 and the pump cover 3, and a passage The medium inlet 11 and the medium outflow 12 connected by the flow channel 6 , the impeller 5 is linked with the rotating shaft 4 and extends into the flow channel 6 . In the embodiment of the present invention, the impeller 5 is selected as an open impeller. After setting in this way, the impeller 5 can be directly processed into shape, and the machining accuracy is easy to ensure, avoiding that the flow path of the closed impeller is too narrow to be cast, and the open impeller The blades are not closed, and when conveying the medium with particles, the particles in the medium will not accumulate in the impeller 5 to caus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com