Adjustable two-stage supercharging sequential system applied to V-shaped diesel engine

A two-stage supercharging and diesel engine technology, which is applied to mechanical equipment, combustion engines, machines/engines, etc., can solve problems such as inability to adjust, limited adjustment range, and limited boost ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The embodiments of the present invention are described in detail below. Based on the premise of the technical solution of the present invention, the present embodiment provides detailed implementation and specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

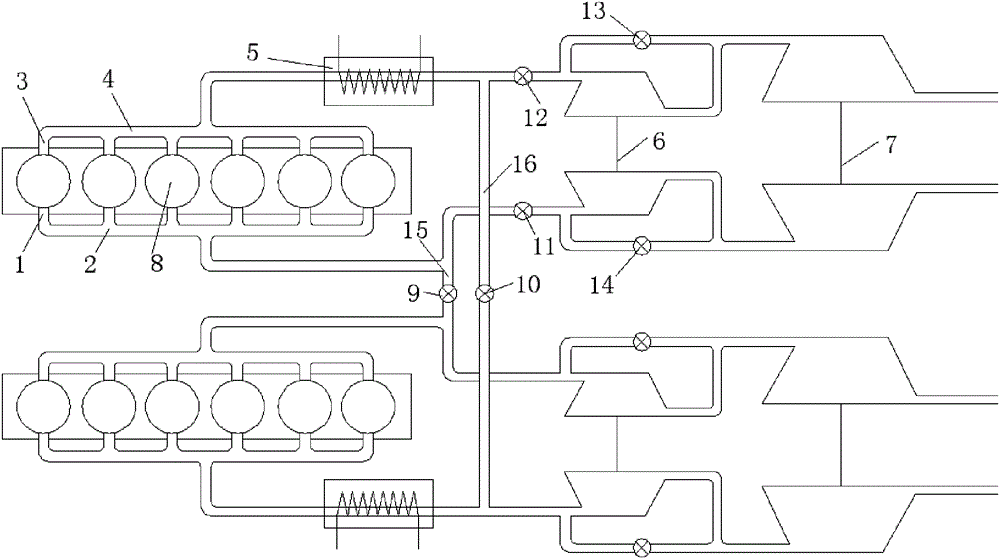

[0015] like figure 1 As shown, this embodiment provides an adjustable two-stage supercharging sequence system applied to a V-type diesel engine, including an exhaust branch pipe 1, an exhaust main pipe 2, an intake branch pipe 3, an intake main pipe 4, an intercooler 5, High-pressure turbocharger 6, low-pressure turbocharger 7, turbine control unit, compressor control unit, intake control unit, exhaust control unit, the inlet of the exhaust branch pipe is connected to the exhaust port of the cylinder head 8, The outlet of the exhaust branch pipe 1 is connected to the exhaust manifold 2, and the high-pressure stage turbocharger 6 is connected in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com