Connecting pieces for overall installation of solar panels of large-span hemispherical roof and installation method thereof

A technology of solar panels and connectors, which is applied to roofing, roof cladding, and building materials, can solve problems such as poor resistance to external forces, long construction time, and high cost, and achieve good resistance to external forces and reduce construction time. , The effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1, such as Figure 8 to Figure 10 As shown, the solar panel butt joint 3 is a solar panel 4 with 90° flanging 31 at both ends, and several thorn-shaped protrusions 32 are provided on the outside of the flanging 31 , the said solar panel sheet butt joint 3 is a clamping piece that can clamp the flanging 31 of two opposite solar panels, and the clamping piece is a bottomless frame 33, in the clamping piece The inner side is provided with inverted teeth 34 that can engage with the protrusions, and there is also a connecting bracket 36 connecting the steel frame 35 at the middle position of the flanges 31 of the two sun panels clamped by the clamping parts. The upper end of the group is provided with an end cap 37, and the lower end of each connected solar panel group 5 is provided with a water diversion plate 38, and the upper end of the connecting bracket 36 is provided with a connecting rod 39 arranged horizontally, and the lower end of the connecting bracket 36 ...

Embodiment 2

[0035] Example 2, such as Figure 5 to Figure 7As shown, the upper and lower solar panel connectors 2 are composed of an end connector 21 of a whole solar panel and a middle connector 22 of a whole solar panel, and the end connector 21 further includes: Connector main body 212 on the main purlin 211 of the steel grid frame, the two sides of the lower part of the connector body 212 are provided with L-shaped connecting plates 213; On the purlin 211, the middle part of the connector main body 212 is provided with a slot 216 for inserting the lower solar panel 215, and the top of the connector main body 212 is provided with a connection hole for fixing the lower solar panel 215, and the top of the connector main body 212 is also Lap the upper solar panel 217, set the fastening bolt 214 in the connecting hole, the lower part of the middle connector 22 is a rectangular frame 221; The lower part of the lower part is sleeved on the middle and secondary beams 223 and fastened to the ...

Embodiment 3

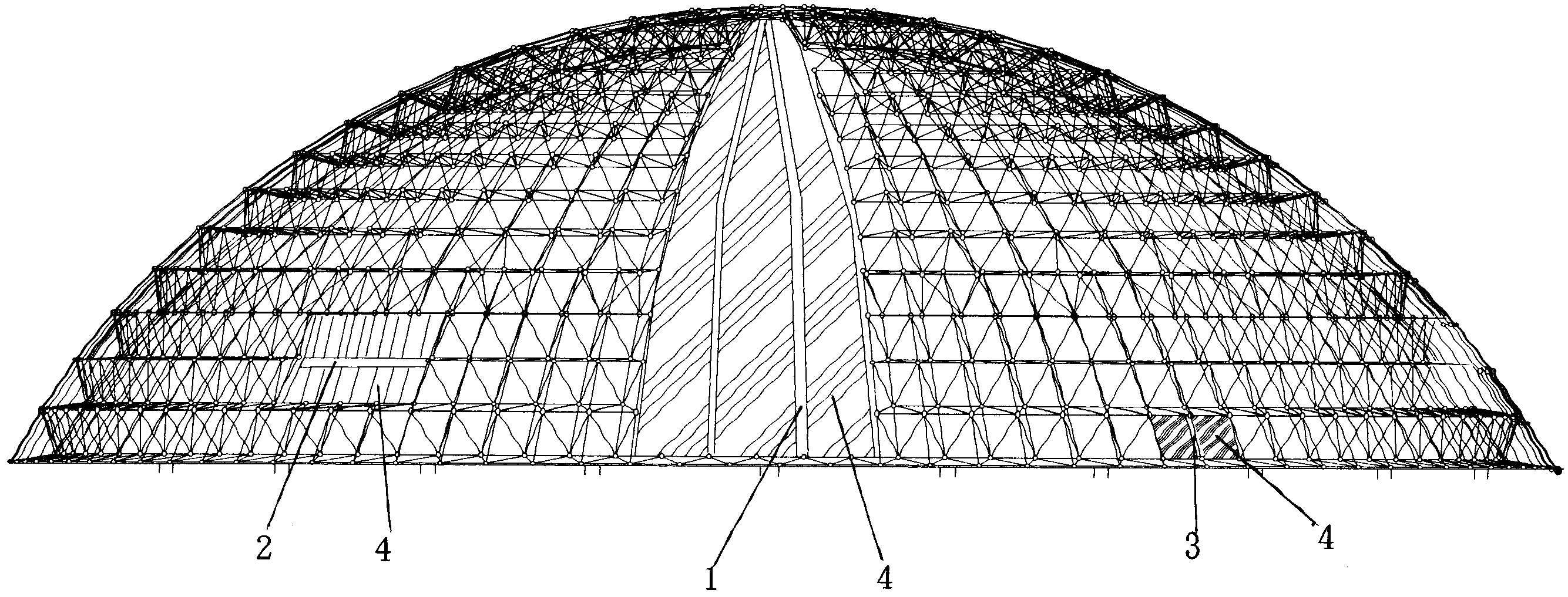

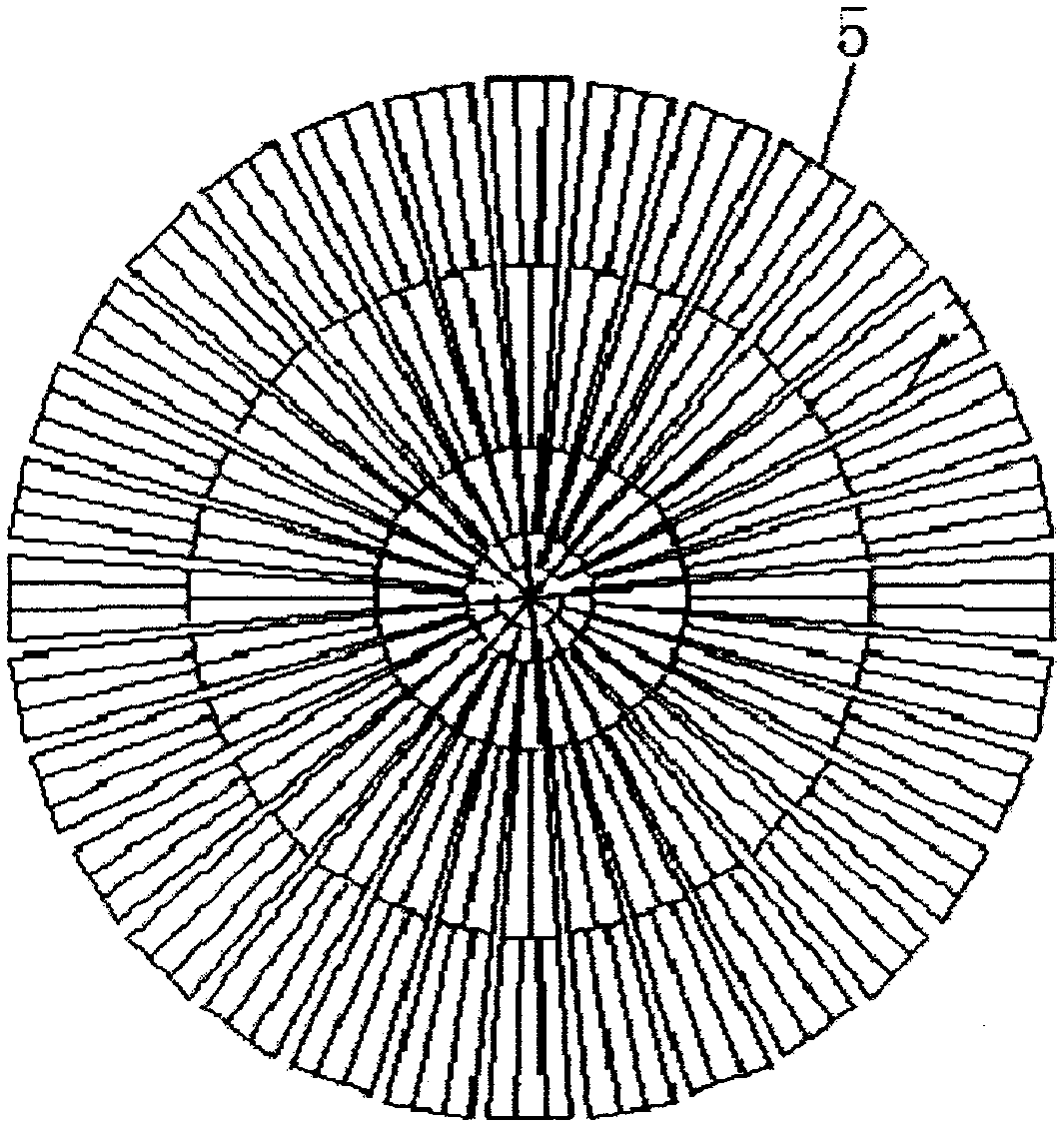

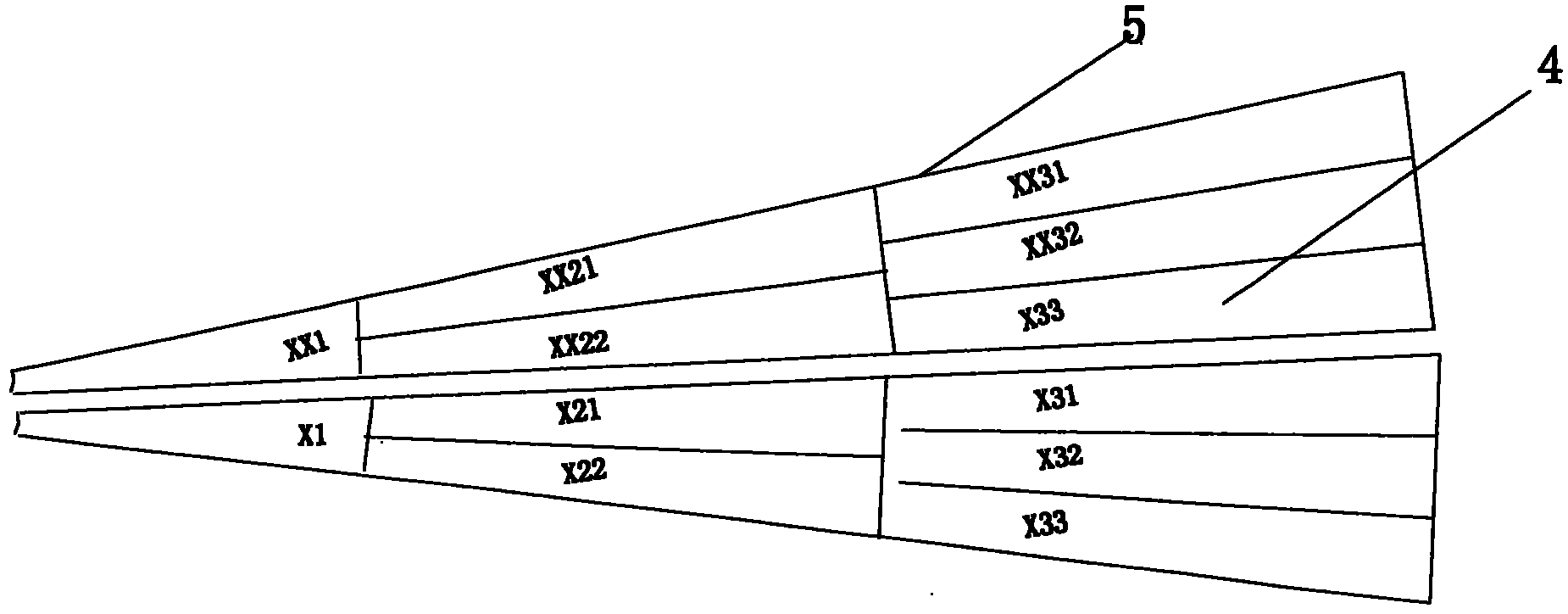

[0037] Example 3, such as Figure 1 to Figure 2 As shown, the connecting piece for the connection of the roof sunlight plate is divided into several block-shaped fan-shaped areas on the large-span hemispherical roof, the sun panels are set in the fan-shaped areas, and the connecting pieces are set between the sun panels in the fan-shaped areas connection, such as Figure 3 to Figure 4 As shown, the piece connection includes an integrally designed upper connector 11 and an integrally designed lower connector 12, the lower connector 11 is fixed on the steel roof secondary beam 121, the upper connector 11, the lower connector 12 Clamp the sun panel groups 5 in the fan-shaped areas on both sides, the top cover 112 is set in the middle of the upper connecting piece 11, the lower connecting piece 12 includes a bottom bearing surface 122, and the two sides on the bottom bearing surface 122 are set One or more sets of upper ejector rods 123, the middle part of the bottom bearing surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com