Filler dust eliminating apparatus used in baking tunnel during baking process of graphite manufacturing process

A manufacturing process and roasting technology, applied in the field of dust devices, can solve the problems of dust and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

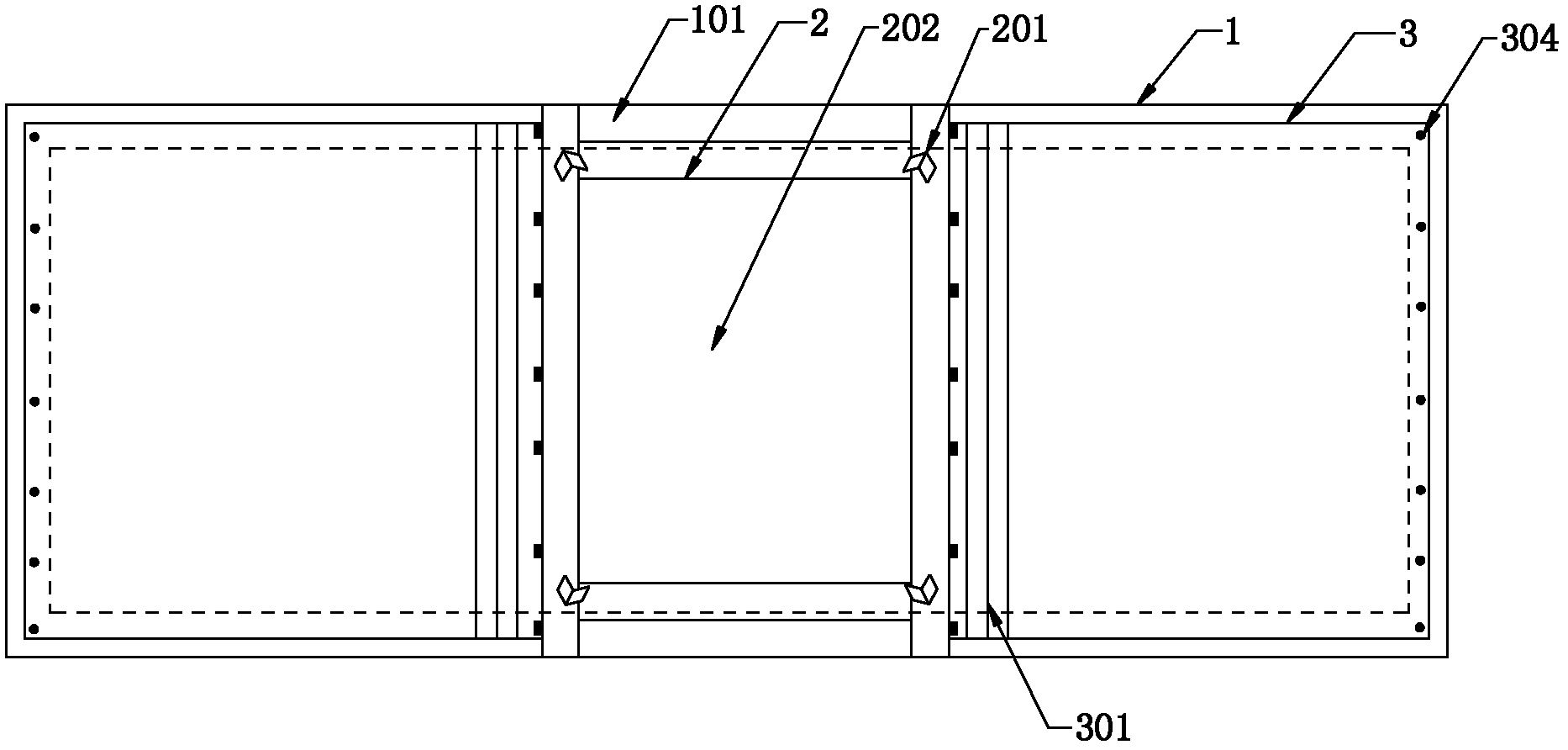

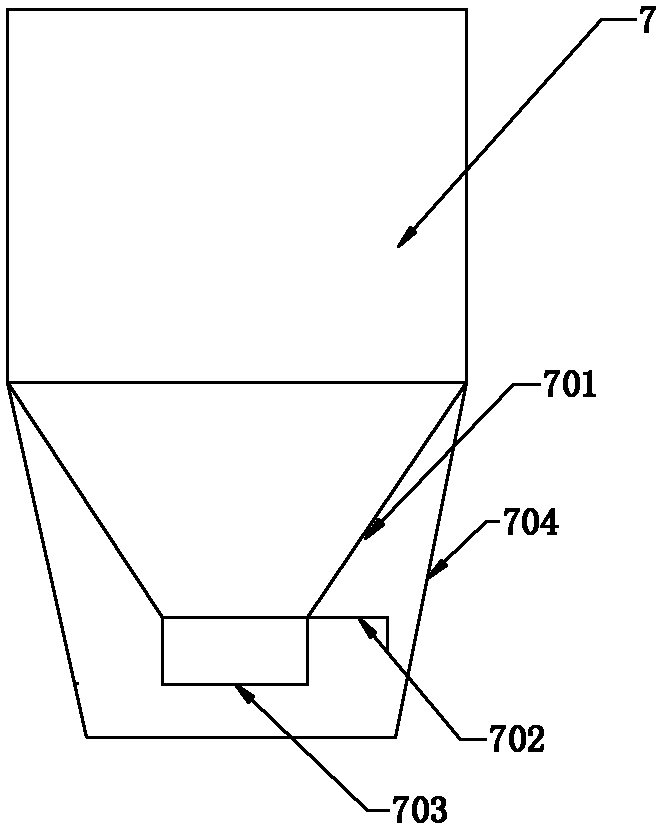

[0025] Such as figure 1 , 2 , shown in 3, the present invention is set a rectangular base frame 1 that shape is identical with the pit mouth of the roasting tunnel but the area is greater than the pit area by the pit mouth area of a single roasting tunnel, the base frame 1 is placed on the pit mouth of the roasting tunnel, the base Axial slide rails 101 are installed on both sides of the long axis of the frame, and a hopper frame 2 is movably placed on the base frame. The hopper frame is composed of four sides. The hopper 7 for filling materials, the bottom of the hopper is a protruding conical bottom 701, the top of the conical bottom is a discharge port 703, a movable insert 702 is set on the discharge port, and the hopper frame is set on the side in contact with the axial slide rail There is a sliding device 4, and the sliding device can use pulleys, balls or wire ropes to pull the movement mechanism, so that the hopper frame can move back and forth above the roasting tu...

Embodiment 2

[0030] Such as figure 1 , 2 , 4, 5, and 6, on the basis of the aforementioned embodiments, since the closed cover 3 is only fixed at both ends, and the middle is not fixed, both sides of the closed cover are supported on the axial slide rail 101 or the base frame 1 On both sides of the closed cover, when the hardness of the closed cover itself cannot support its own weight, the middle of the closed cover will fall into the roasting tunnel and lose the effect of blocking dust. A support rod 302 is provided, and the two ends of the support rod are supported on both sides of the axial slide rail or the base frame, and the support rod can be a rod, strip or plate with a certain supporting strength such as steel bar or plastic. Support bar can utilize ropes such as iron wire to be fixed on the closure cover, and the distance of support bar interval is set according to the hardness of closure cover.

Embodiment 3

[0032] Such as Figure 7 As shown, on the basis of the second embodiment, a slot 102 is provided on both sides of the base frame 1. The opening diameter of the slot is smaller than the inner diameter of the slot. Blocks 303 are provided on both sides of the closure cover 3. The shape of the block is The cross-sectional shape is the same as that of the card slot. After the card block is inserted into the card slot, the card block cannot come out from the opening of the card slot but can slide in the card slot. The blocks are also arranged at intervals, so that when the hopper frame is moving, the blocks on both sides will contact or separate from each other, and the connected closing cover will be folded or unfolded to ensure the sealing of the pit mouth.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com