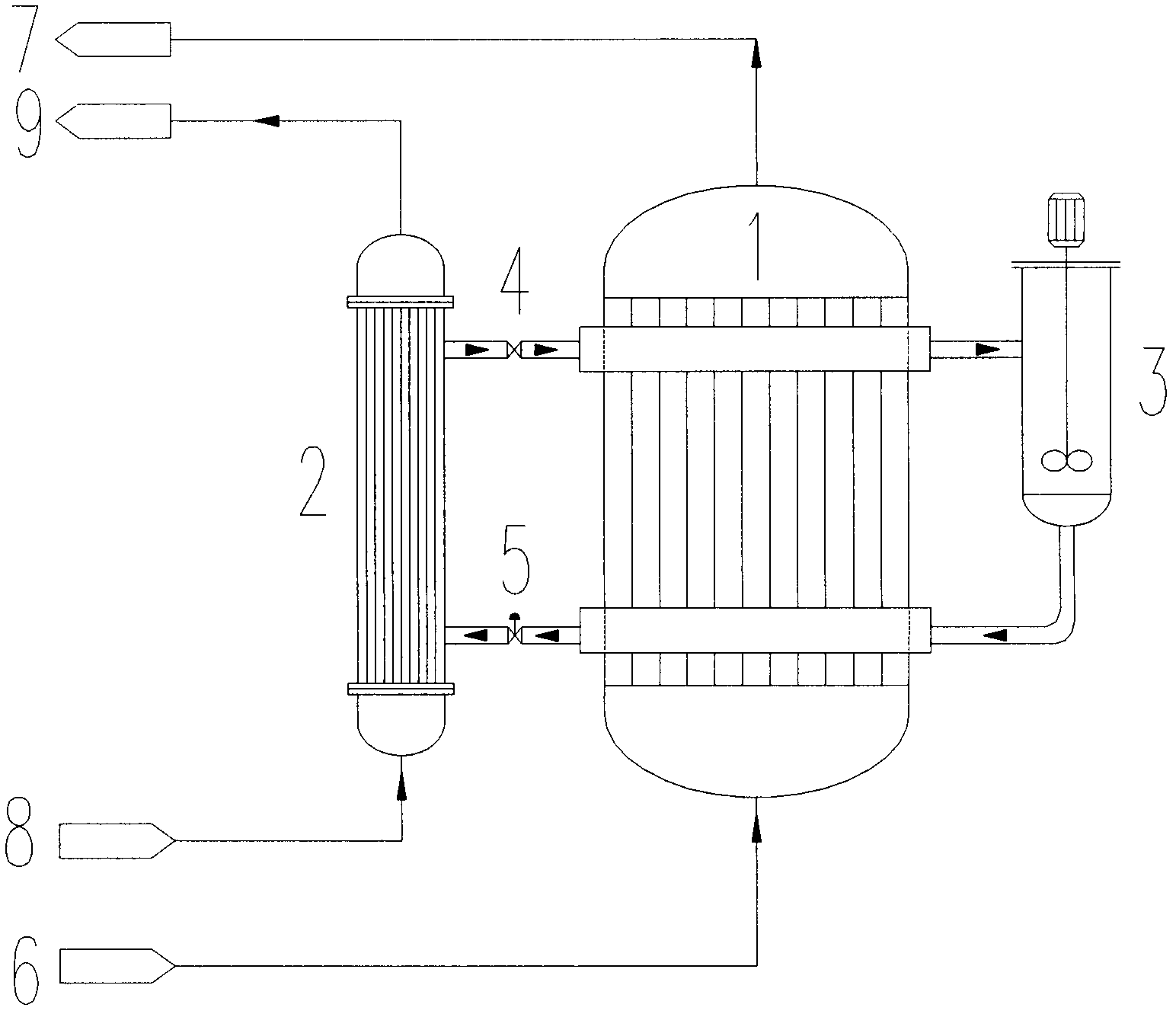

Oxidation reaction temperature regulation control device and method in fixed bed maleic anhydride production with normal butane method

A technology for oxidation reaction and temperature adjustment, which is applied in chemical instruments and methods, valve devices, organic chemistry, etc., and can solve problems affecting conversion rate and selectivity, maleic anhydride yield, reaction temperature changes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The working condition is the same as that of the comparative example:

[0048] When the molten salt temperature in the reactor (shell side) deviates from the process parameter control value (high or low), the control signal is output to the electric actuator 10 of the slide valve through the DCS (distributed control system), and the valve core is controlled through the connecting rod 19 18. Adjust the stroke opening of the slide valve spool 18 to move the spool up or down, and change the flow rate of the high-temperature molten salt outlet 13 by changing the overlapping flow area with the flow hole on the valve seat 17, so as to control the flow through the molten salt cooling The molten salt flow rate of the reactor is controlled to achieve the purpose of controlling the molten salt temperature on the shell side of the reactor.

[0049] Part of the high-temperature molten salt flowing through the shell side in the reactor controls the flow rate of the molten salt flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com