Resin catcher used in industrial water processing system

A technology of industrial water treatment and resin traps, which is applied in chemical instruments and methods, fixed cartridge filters, filtration separation, etc., can solve the inconvenience of manufacturing and maintenance, the weight of a single device and the increase in floor area, and the thickness of the wall Problems such as increase in size and size, to achieve the effect of reducing workload, weight, size and floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

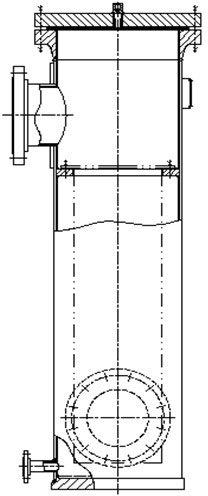

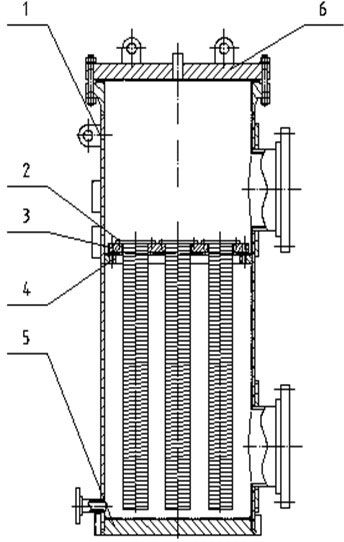

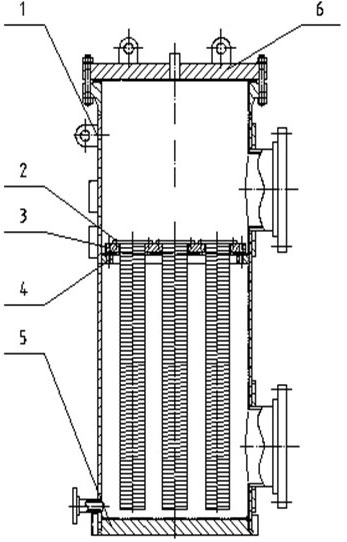

[0015] A specific embodiment of the present invention: a resin trap for an industrial water treatment system, mainly comprising a cylinder 1 , a filter element 2 , a filter element tube plate 3 , a filter element tube plate mounting ring 4 , a bottom plate 5 , and a cover plate 6 .

[0016] This resin trap is especially suitable for industrial water treatment systems with a flow rate of 500~4000m3 / h.

[0017] The cylinder body 1, the bottom plate 5, and the filter element tube plate mounting ring 4 in this resin trap form a whole by welding, the filter element 2 and the filter element tube plate 3 are connected watertightly, and the filter element 2 and the filter element tube plate 3 are connected and installed with the filter element tube plate Ring 4 is watertightly connected. Install the element through the mounting ring of the element tubesheet. The number and size of filter elements can be matched and adjusted according to the water treatment capacity of the system. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com