Film peeling method

A film and pitch technology, used in household appliances, metal processing, adhesives, etc., to achieve the best efficiency and less waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

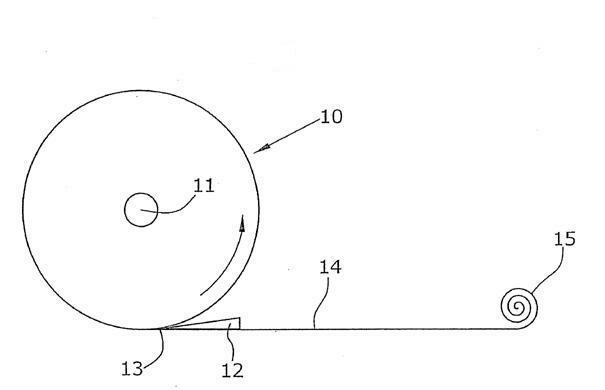

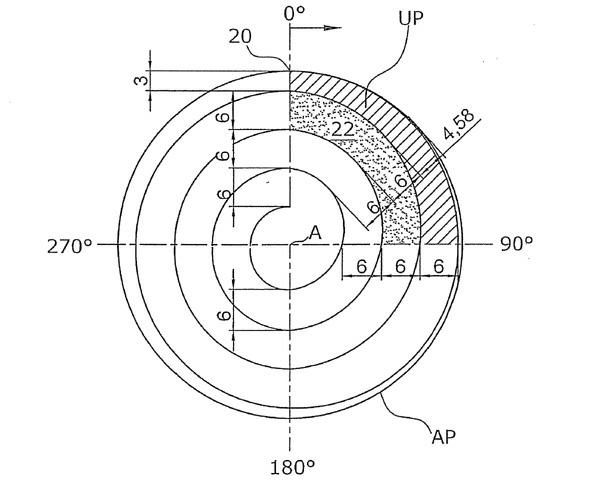

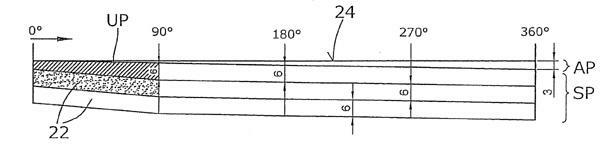

[0020] figure 1 A block 10 of foam material to be processed into a foam film is shown. The block of material 10 is substantially cylindrical. It sits on a shaft 11 which passes through the block of material along its axis. A blade 12 is disposed against the block of material, the blade being disposed on an adjustable knife bar substantially tangential to the block of material and having a cutting edge 13 . The blade may be an endless knife band. The position of the blade relative to the block of material 10 is controlled by control means such that as the block of material 10 rotates, the blade moves radially towards the axis A at a constant speed so that the blade follows a general helical shape relative to the block axis. track. The blade peels the film 14 from the block of material, and the film 14 is wound into a roll 15 . The withdrawal device ensures that the film 14 moves at a constant transport speed, ie independent of the different radii of the material blocks.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com