Complex chemical process modeling method of hybrid DNA (Deoxyribose Nucleic Acid) genetic algorithm

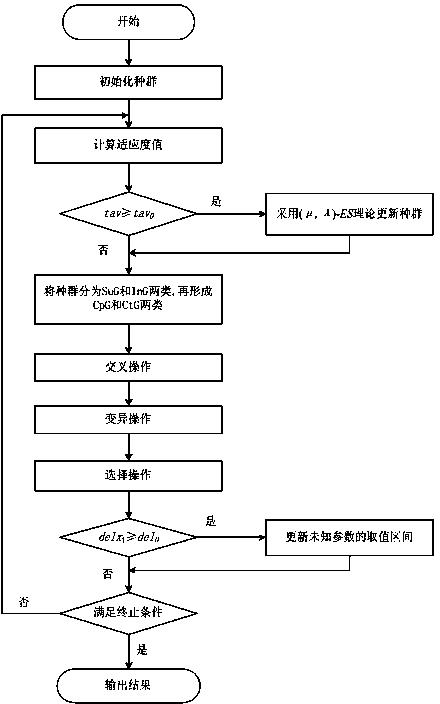

A chemical process and genetic algorithm technology, applied in the field of complex chemical process modeling, can solve the problems of low search efficiency, easy precociousness, poor local search ability, etc., to improve diversity, good application and development prospects, and enhance global search ability. and the effect of local optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] The method of the present invention is used in the five lumped combination reactor model parameter estimations of distillate oil catalytic cracking process, further detailed description is as follows:

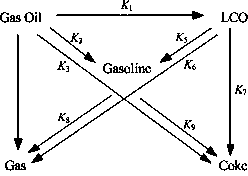

[0062] Residual oil catalytic cracking (RFCC) is a chemical process in which heavy oil is cracked in a riser reactor under a regenerated catalyst and a certain temperature and pressure. In its lumped kinetic reaction model, each lump can be considered as a virtual single component, and then the reaction network of these virtual lumped components can be developed, so that simplified lumped kinetics can be established A dynamic model of the network. According to the characteristics of the catalytic cracking reaction of distillate oil, the reaction system is divided into five types: raw material oil (Gas Oil), light cycle oil (LCO), gasoline (Gasoline), gas (Gas), and coke (Coke) by using the lumped method. virtual lumped components, reflecting networks such as image 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com