Method for determining gelatinization temperature and gelatinization degree of starch

A technology of starch gelatinization and determination method, which is applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problem that starch gelatinization cannot be characterized, and achieve the effect of reducing experimental workload and high statistical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

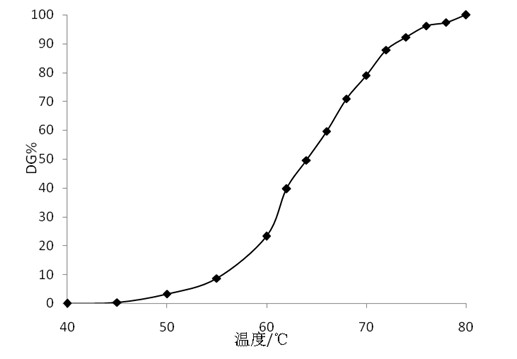

[0059] Example 1: Used to measure the gelatinization temperature and crystal characteristic gelatinization curve of corn starch

[0060] The corn starch emulsion system with a mass concentration (dry basis) of 5% was simulated, and the change of starch gelatinization degree during the continuous heating process was detected.

[0061] 1. Taking digital photos. Including the following steps and process conditions:

[0062] (1) Prepare a corn starch emulsion with a mass concentration (dry basis) of 5%, and equilibrate it at room temperature for 2 hours. Stir the balanced starch milk vigorously to stir up the sunken starch and distribute it more evenly in the system. Take 60μl of starch milk with the dropper, quickly add two to three drops to the center of the glass sheet that has been coated with a circle of sealant on the edge, and use the tip of the dropper to make the starch milk evenly distributed, and then cover with another sheet Glass sheet, press to seal. The film prod...

Embodiment 2

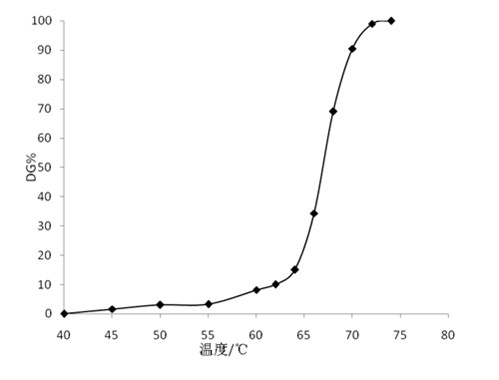

[0080] Embodiment 2: for measuring the gelatinization temperature and crystal characteristic gelatinization curve of pea starch.

[0081] The pea starch emulsion system with a mass concentration (dry basis) of 10% was simulated to detect the change of starch gelatinization degree during the continuous heating process.

[0082] It is used to determine the gelatinization process of pea starch in an emulsion with a water content of about 90%.

[0083] 1. Taking digital photos.

[0084] Including the following steps and process conditions:

[0085] (1) Prepare a pea starch emulsion with a mass concentration (dry basis) of 10%, equilibrate it at room temperature for 1 hour, and vigorously stir the balanced starch milk to stir up the sunken starch and distribute it more evenly in the system. Take 80μl of starch milk with the dropper, quickly drop two to three drops to the center of the glass sheet that has been coated with a circle of sealant on the edge, and use the tip of the dr...

Embodiment 3

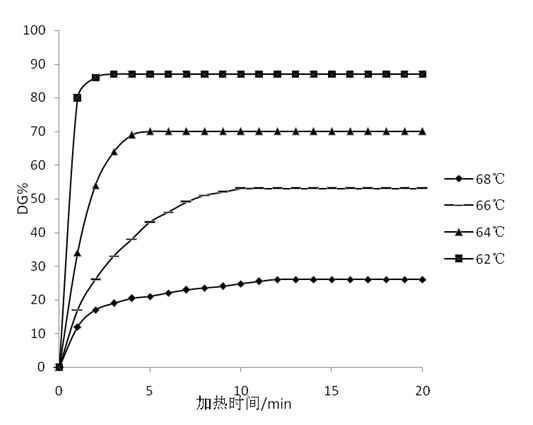

[0103] It is used to control the heating temperature and heating time in the preparation process of partially gelatinized potato starch milk, and to prepare potato starch products with different degrees of gelatinization.

[0104] The potato starch emulsion system with a mass concentration (dry basis) of 20% was simulated to detect the change of starch gelatinization degree during the heat preservation process.

[0105] 1. Taking digital photos.

[0106] Including the following steps and process conditions:

[0107] (1) Configure a potato starch emulsion with a mass concentration (dry basis) of 20%, and equilibrate it at room temperature for 1.5 hours. Stir the balanced starch emulsion vigorously to stir up the sunken starch and distribute it more evenly in the system. Take 50μl of starch milk with the tip dropper, quickly drop two to three drops to the center of the glass sheet that has been coated with a circle of sealant on the edge, and stroke with the tip of the glue tip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com