Moisture-resistant breathable wood floor and manufacturing process thereof

A production process, wood flooring technology, applied in the field of wood flooring, can solve the problems of paint peeling, expansion cracking, economic and spiritual losses of enterprises and consumers, etc., and achieve the effect of good moisture resistance and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

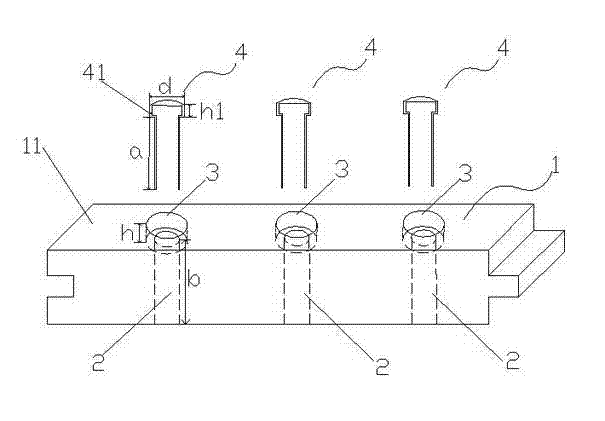

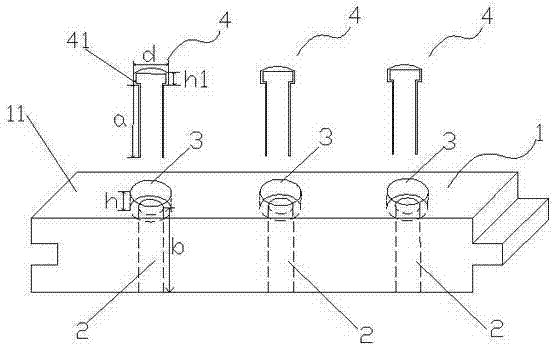

[0020] like figure 1 As shown, the moisture-resistant and air-permeable solid wood floor of the present invention includes the wood floor 1 after grooves on four sides. Several through holes 2 are arranged on the upper surface 11 of the wooden floor, and the central axis of each through hole 2 is perpendicular to the upper surface of the wooden floor. And the distance between the above-mentioned through holes 2 is 200-300 mm. A blind hole 3 having the same central axis as the through hole 2 is also provided on the upper surface of the wood floor where any one of the through holes 2 is located. The aperture of the blind hole 3 is 20-25mm, and the aperture of the through hole is 10-15mm. The depth h of the blind hole is 3 mm (the depth of the blind hole can also be adjusted appropriately during actual production); a matching rivet 4 is arranged in any of the above-mentioned through holes 2, and the rivet 4 is hollow, and the round cap of the rivet 4 is surrounded by Several sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com