Straightening annealing method for titanium and titanium alloy plates

A technology for titanium alloys and plates, applied in the field of preparation of titanium and titanium alloy plates, can solve the problems of difficult removal, long annealing time, and inability to meet the requirements of high flatness of plates, and achieves the effect of reducing the force-bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

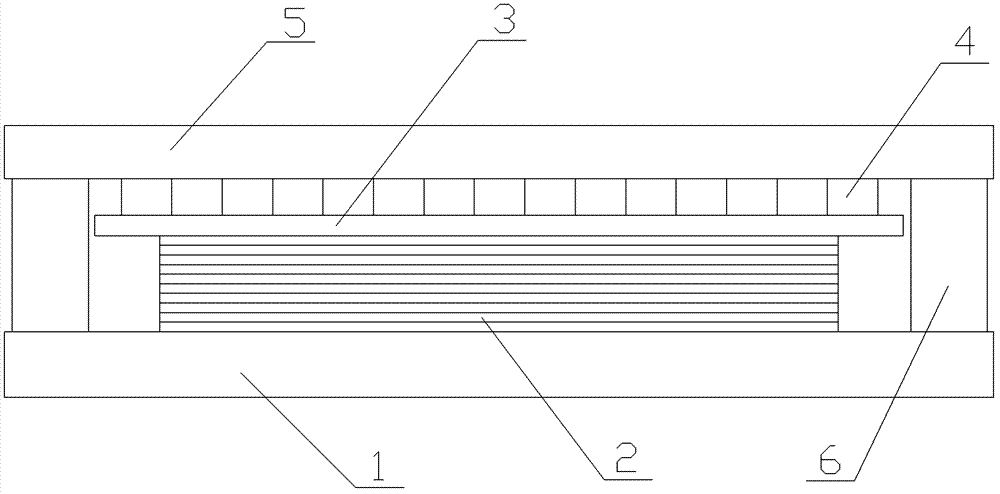

[0030] Step 1, such as figure 1 As shown, a pure titanium backing plate 1 with a thickness of 12mm and an unevenness not greater than 3mm / m is placed on the tray of a 3m vacuum annealing furnace, and then 50 TA2 plates 2 to be processed are neatly stacked in the center of the backing plate 1 ; The size specification of the plate 2 is 0.6mm×600mm×1000mm;

[0031] Step 2. Place a pure titanium isolation pad 3 with an unevenness not greater than 3mm / m and a size of 1.0mm×700mm×1100mm on the uppermost plate, and then spread 240 ordinary carbon steel briquettes 4 on the isolation pad On the plate 3 and make the tiled area of the pressing block 4 completely cover the plate 2 to be processed, the size of the pressing block 4 is 10mm×50mm×50mm, the height tolerance of the pressing block 4 is not more than 1mm, and the edges of the pressing block 4 are smooth ;

[0032] Step 3: Place the counterweight pressing plate 5 with a weight of 2102 kg on the pressing block 4 described in st...

Embodiment 2

[0039] Step 1, such as figure 1 As shown, place a pure titanium backing plate 1 with a thickness of 70mm and an unevenness not greater than 3mm / m on the tray of a 3m vacuum annealing furnace, and then neatly stack 20 TC4 plates 2 to be processed on the center of the backing plate 1 ; The size specification of the plate 2 is 1.0mm×1336mm×2418mm;

[0040] Step 2. Place a pure titanium isolation backing plate 3 with an unevenness not greater than 3mm / m and a size of 1.0mm×1400mm×2500mm on the uppermost plate, and then place 334 ordinary carbon steel briquetting blocks weighing 5kg in 4 levels Lay on the isolation pad 3 and make the tiled area of the pressing block 4 completely cover the plate 2 to be processed. The size of the pressing block 4 is 60mm×100mm×100mm, and the height tolerance of the pressing block 4 is not greater than 1mm. 4 smooth edges;

[0041] Step 3: Place the counterweight pressing plate 5 with a weight of 3230kg on the pressing block 4 mentioned in step 2...

Embodiment 3

[0048] Step 1, such as figure 1 As shown, a pure titanium backing plate 1 with a thickness of 70 mm and an unevenness not greater than 3 mm / m is placed on the tray of a 3 m vacuum annealing furnace, and then 30 TA1 plates 2 to be processed are neatly stacked in the center of the backing plate 1 ; The size specification of the plate 2 is 1.0mm×800mm×2000mm;

[0049] Step 2. Place a pure titanium isolation pad 3 with an unevenness not greater than 3mm / m and a size of 1.0mm×850mm×2100mm on the uppermost plate, and then spread 250 ordinary carbon steel briquettes 4 on the isolation pad On the plate 3 and make the flat area of the pressing block 4 completely cover the plate 2 to be processed, the size of the pressing block 4 is 100mm×80mm×80mm, the height tolerance of the pressing block 4 is not more than 1mm, and the edges of the pressing block 4 are smooth ;

[0050] Step 3: Place the counterweight pressing plate 5 with a weight of 2821 kg on the pressing block 4 described in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com