External lubricant for polyvinyl chloride (PVC) resin forming and processing and production method thereof

A PVC resin, molding and processing technology, applied in the field of external lubricants for PVC resin molding and processing and its preparation, can solve the problems of reducing production efficiency, easy precipitation, increasing production cost, etc., and achieves the improvement of product performance and production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Prepare the external lubricant for PVC resin molding processing of the present invention according to the following steps

[0063] ①. Mixed monomer preparation

[0064] a. Nuclear layer mixed monomer

[0065] According to the predetermined formula, accurately weigh 140 parts by weight of styrene and 10 parts by weight of isooctyl glycolate, mix them evenly, and set aside;

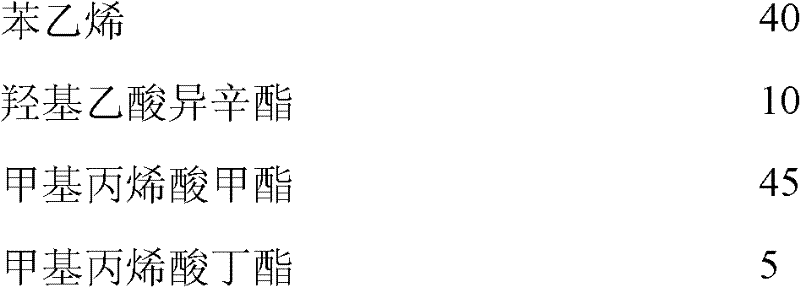

[0066] b. Shell mixed monomer

[0067] According to the predetermined formula, accurately weigh 45 parts by weight of methyl methacrylate and 5 parts by weight of butyl methacrylate, mix them evenly, and set aside;

[0068] ②. Core layer emulsion polymerization

[0069] Put 100 parts by weight of deionized water and 1.5 parts by weight of sodium dodecylbenzene sulfonate into the reaction kettle. Under stirring, put into the nuclear layer mixed monomer prepared in step a, heat up to 75°C, and add 0.3 weight of potassium persulfate It will be polymerized for 2 hours at a temperature of 80~85℃, and the temperature...

Embodiment 2~ Embodiment 6

[0076] According to the method and steps of Example 1, according to the formula in Table 1, the external lubricant for PVC resin molding processing of the present invention was prepared

[0077] Table 1

[0078] Raw materials

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com