Steam pressure relief method and device for sludge hydrothermal drying steam pyrolysis reaction kettle

A technology of pyrolysis reactor and sludge water, which is applied in the direction of pyrolysis treatment of sludge and vaporization of by-products, etc., and can solve problems such as affecting the use of equipment and blocking the discharge device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

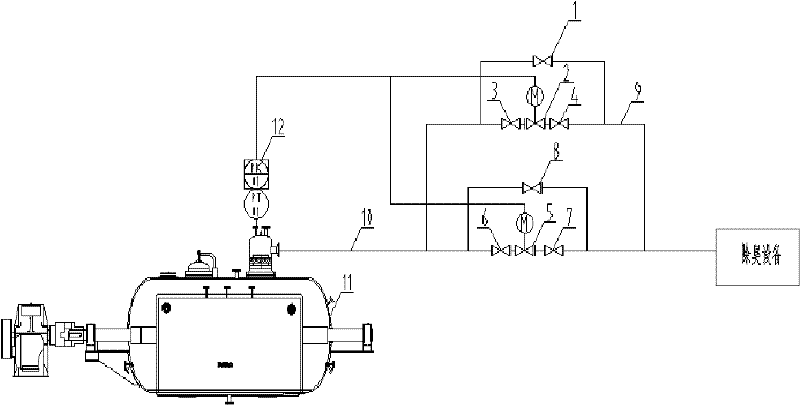

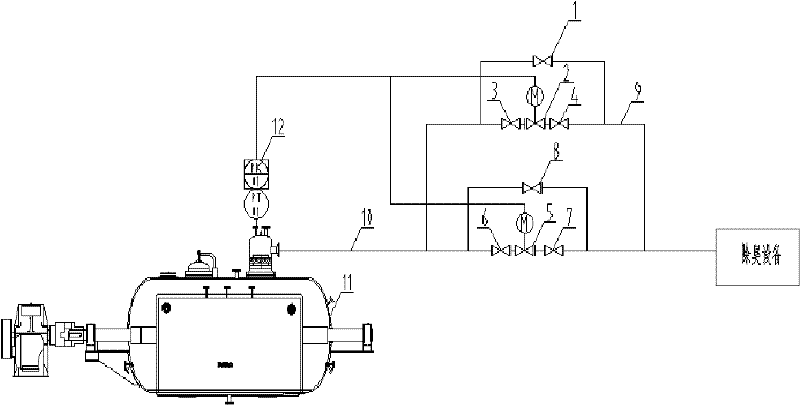

[0020] A steam pressure relief device for a sludge hydrothermal drying steam pyrolysis reactor, comprising: a main steam pressure relief pipeline, a bypass pressure relief pipeline, and electric shut-off valve groups on each pipeline;

[0021] First manual stop valve 1, first electric stop valve 2, second manual stop valve 3, third manual stop valve 4, second electric stop valve 5, fourth manual stop valve 6, fifth manual stop valve 7, The sixth manual shut-off valve 8, the main steam pressure relief pipeline 10, the bypass pressure relief pipeline 9, the steam pyrolysis reactor 11, and the steam pyrolysis reactor pressure gauge 12.

[0022] The first electric shut-off valve 2, the second manual shut-off valve 3, and the third manual shut-off valve 4 are connected in series. The first manual shut-off valve 1 and the first electric shut-off valve 2, the second manual shut-off valve 3, and the third The manual shut-off valve 4 is connected in parallel, the other end of the first manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com