Automatic tray library

A pallet library and automatic technology, applied in the field of sub-packaging and conveying equipment and automatic pallet storage, can solve the problems of lack of automation, inconvenience, and lack of pallets, and achieve the effect of automatic storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below with reference to the accompanying drawings.

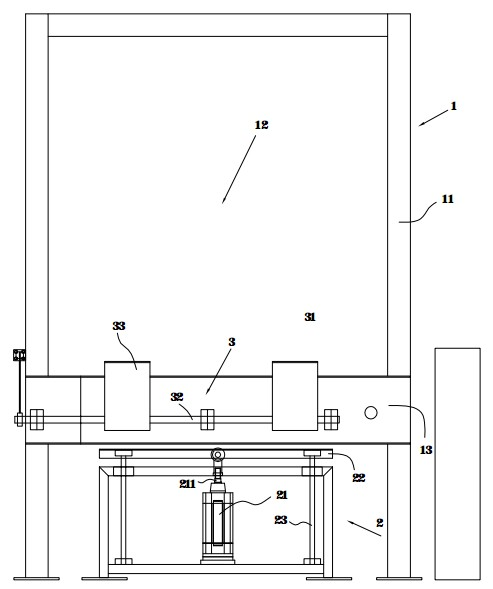

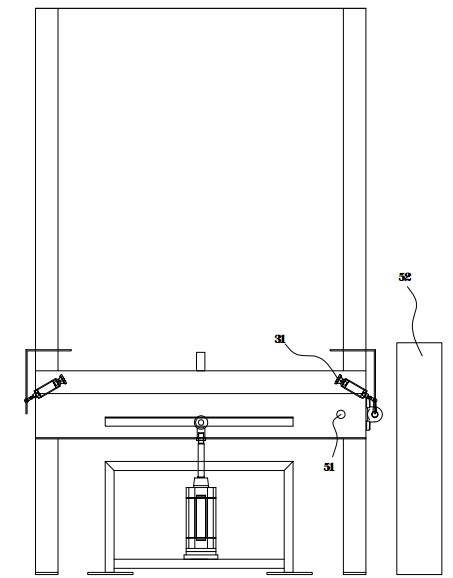

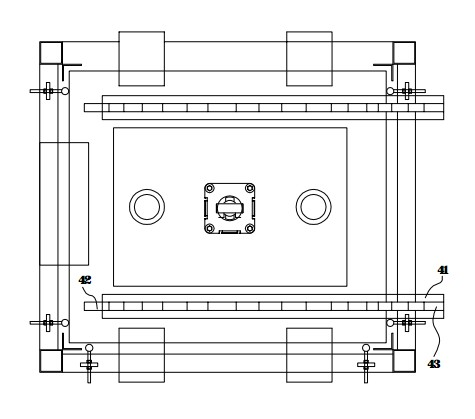

[0019] Such as Figures 1 to 3 As shown, an automatic pallet warehouse includes a frame 1, and the frame 1 includes four uprights 11, the uprights 11 enclose a pallet warehouse 12, and crosspieces 13 are also arranged between the uprights 11. A lifting mechanism 2 is provided in the frame 1, and the lifting mechanism 2 includes a lifting cylinder 21. The lifting cylinder 21 is provided with a liftable push rod 211, and the push rod 211 is connected to the supporting plate 22, and the supporting plate 22 is also connected with four pillars 23. Tray is placed on the pallet 22 . Both sides of frame 1 are provided with separating device 3, and separating device 3 comprises separating cylinder 31, and separating cylinder 31 is installed on the crosspiece 13, and cylinder 31 is connected to push shaft 32, and the two ends of push shaft 32 are provided with bearings, and beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com