Hydraulic control system and engineering machine

A technology of hydraulic control system and braking system, which is applied in the fields of construction machinery and hydraulic control system, can solve the problems of scattered structure and layout of the whole machine, increased components, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

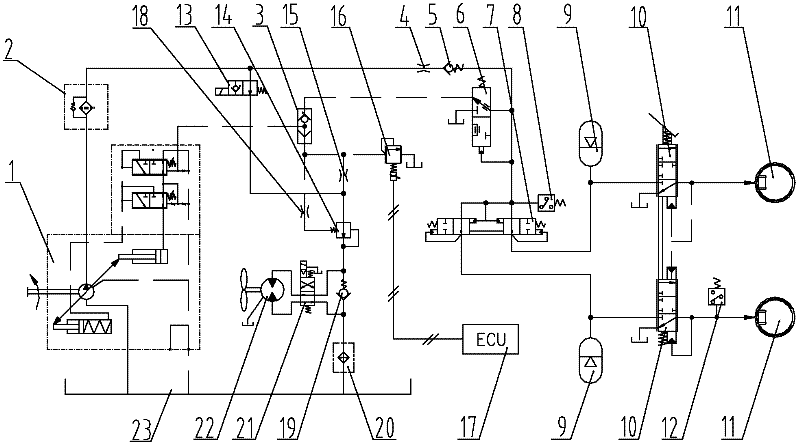

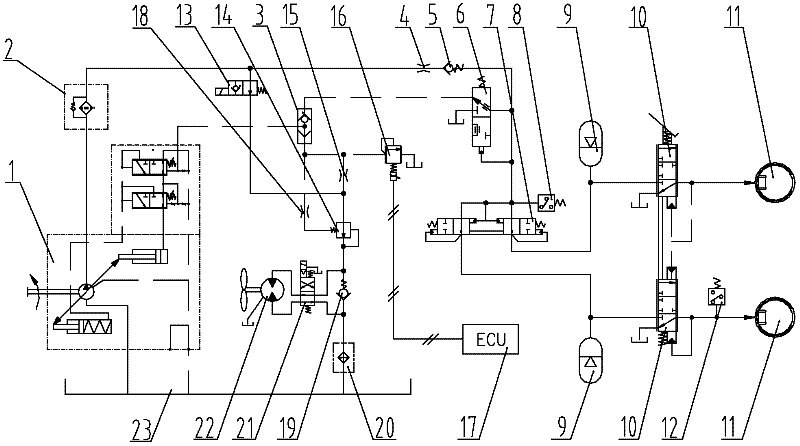

[0015] Below will combine the preferred embodiment of the present invention figure 1 , clearly and completely describe the technical solutions in the embodiments of the present invention.

[0016] The invention provides a hydraulic control system, which is applied to engineering machinery such as graders, off-road cranes, loaders and the like. The hydraulic control system includes a load-sensing variable pump 1, a filter 2 connected to the load-sensing variable pump 1, a shuttle valve 3, a braking system and a cooling system integrated with the braking system.

[0017] The load sensitive variable pump 1 is used for adaptively controlling the power of the fan motor 22 and the brake 11 . The load sensitive variable pump 1 has pressure and flow adaptive characteristics, and it can output pressure oil suitable for the working pressure of the fan motor 22 , thereby realizing the rotation of the fan motor 22 . The load sensitive variable pump 1 can also output pressure oil suitabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com