Method for manufacturing one-piece-formed glass magnesium flue air pipe

A glass-magnesium flue and production method technology, applied in ceramic molding machines, manufacturing tools and other directions, can solve the problems of excessive material waste, corrosion of nails or steel nails, high labor intensity of workers, etc., to simplify the production process and improve the production. Efficiency, the effect of saving investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

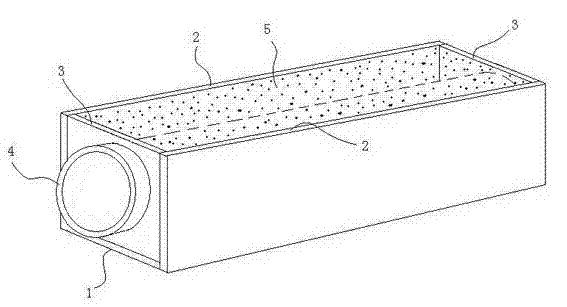

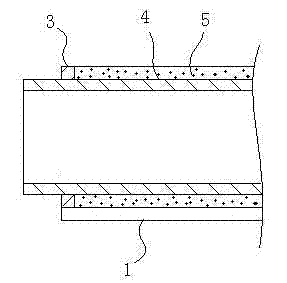

[0027] The manufacturing method of the one-time forming glass magnesium flue duct, such as figure 1 — Figure 6 shown, including the following steps:

[0028] 1. Use three strip-shaped plates to assemble a groove-shaped outer mold with two side plates 2 and a bottom plate 1;

[0029] 2. Brush the mold remover on the inner surface of the outer mold, and then lay medium-alkali or alkali-free mesh cloth;

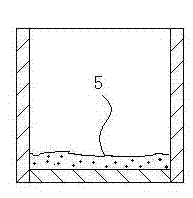

[0030] 3. Lay a layer of glass magnesium production material 5 equivalent to the thinnest thickness of the glass magnesium flue duct wall at the bottom of the outer mold (see image 3 ); Glass magnesium production materials can use the existing technology to produce raw materials for glass magnesium fireproof boards and other products;

[0031] Better glass magnesium production materials can use activated magnesia with a mass percentage of more than 60% as the main material; Add 0.5 kg of active magnesium oxide to 1 kg of intermediate material to prepare an adhesive; then u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com