Shaft system for use in a chuck of a winding head

A winding head and chuck technology, which is used in the field of hollow shafts or hollow shafts, can solve the problems of short grease life of roller bearings, expensive drive shafts or driven shafts, etc., and achieve improved bearing structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] figure 1 A so-called nested shaft system 100 is shown in a schematic view with a central output shaft 1 , which is fixed in rotation at one end of the output shaft with an output element 2 , for example a bushing. connect. Furthermore, the shaft system 100 has a stationary spindle 3 of the bearing bush type, which is arranged coaxially with the driven shaft 1 and accommodates the driven shaft 1 at least partially coaxially in the axial direction.

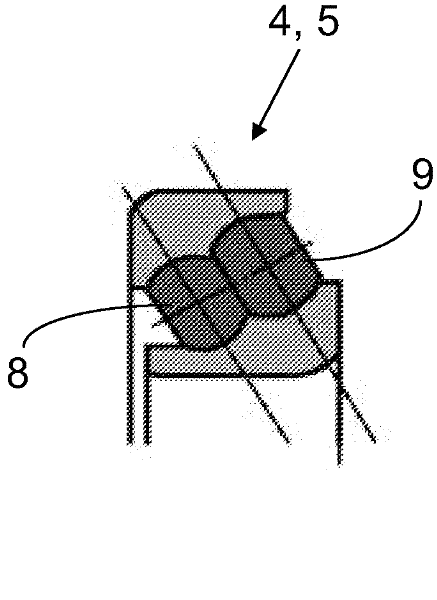

[0027] For supporting the driven shaft 1, the shaft system 100 has at least two rolling bearings 4, 5, which are arranged at a distance from each other in the axial direction, are supported with their outer circumference on the spindle or carrier bushing 3 and with their The inner circumference carries the driven shaft 1. The carrier bushing 3 is supported radially outward via an elastic damping element 6 on a further torsionally fixed spindle 7 arranged coaxially with the output shaft 1 . The torsionally fixed mandrel 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com