Water-repellency cold application filling paste used in optical cable and preparation method thereof

A technology of filling paste and water type, applied in the direction of fiber mechanical structure, etc., can solve the problems of unfavorable factors of optical cable quality, achieve high thixotropic index value and improve quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

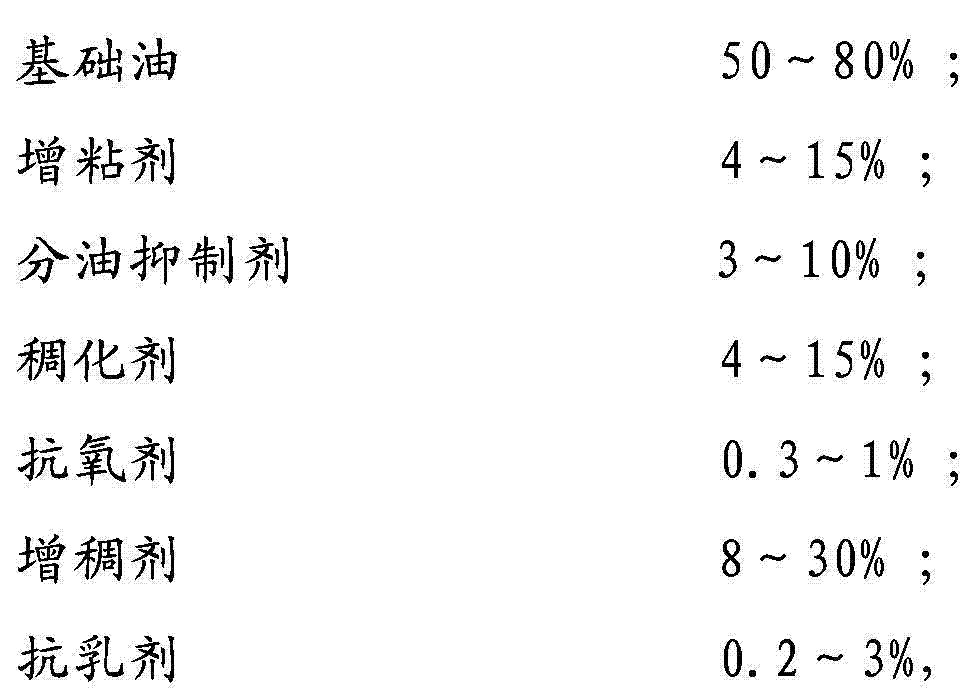

Method used

Image

Examples

Embodiment 1

[0026] Add 100 grams of tackifier to 571 grams of hydrogenated white oil, heat and stir for 0.5 to 1 hour, add 40 grams of oil separation inhibitor, continue to heat and stir for 2 to 5 hours, and when the temperature rises to 150 ℃, Add 80 grams of thickening agent, continue to heat and stir, keep stirring when the temperature reaches 170 ° C, until the thickening agent is completely melted into the base material, then add 4 grams of antioxidant, fully stir for 0.5 to 1 hour, then mix the base material. The material is cooled down to 20 ℃ ~ 60 ℃, then 200 grams of thickener are added, and after fully stirring for 1 to 3 hours, 5 grams of anti-emulsion agent is added, and after fully stirring for 0.5 to 1 hour, a semi-fluid light yellow compound is obtained. After homogeneous grinding and vacuum degassing, the final product is obtained.

[0027] In the above-mentioned raw materials, the tackifier is selected from Shanghai Daopu Chemical International Trade Co., Ltd., the polyi...

Embodiment 2

[0030] Add 90 grams of tackifier to 575 grams of naphthenic rubber oil, heat and stir for 0.5 to 1 hour, add 45 grams of oil separation inhibitor, continue to heat and stir for 2 to 5 hours, when the temperature rises to 150 ° C , add 85 grams of thickening agent, continue to heat and stir, keep stirring when the temperature reaches 170 ° C, until the thickening agent is completely melted in the base material, then add 5 grams of antioxidant, and fully stir for 0.5 to 1 hour. Cool the base material to 20℃~60℃, then add 195 grams of thickener, fully return the material and stir for 1 to 3 hours, add 5 grams of anti-emulsion, and then fully stir for 0.5 to 1 hour to obtain a semi-fluid light yellow The composites were homogenized and degassed in vacuo to obtain the final product.

[0031] Among the above-mentioned raw materials, thickener, oil separation inhibitor, thickener, antioxidant, thickener and anti-emulsion are the same as those in Example 1, and other raw materials are...

Embodiment 3

[0034] Add 85 grams of tackifier to 580 grams of hydrogenated white oil, heat and stir for 0.5 to 1 hour, add 50 grams of oil separation inhibitor, continue to heat and stir for 2 to 5 hours, when the temperature rises to 150 ℃, Add 75 grams of thickening agent, continue to heat and stir, keep stirring when the temperature reaches 170 ° C, until the thickening agent is completely melted into the base material, then add 6 grams of antioxidant, fully stir for 0.5 to 1 hour, then mix the base material. The material is cooled down to 20℃~60℃, then 190 grams of thickener are added, and after fully returning the material and stirring for 1 to 3 hours, 14 grams of anti-emulsion agent is added, and after fully stirring for 0.5 to 1 hour, a semi-fluid light yellow compound is obtained. After homogeneous grinding and vacuum degassing, the final product is obtained.

[0035] Among the above-mentioned raw materials, thickener, oil separation inhibitor, thickener, antioxidant, thickener an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com