Method and system for measuring parameters of bent pipe

A measurement method and pipe bending technology, applied in the field of measurement, can solve the problems of wrong matching of center lines, occlusion, and inability to realize pipe bending measurement, and achieve the effect of flexible and rapid measurement and simplified calculation work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

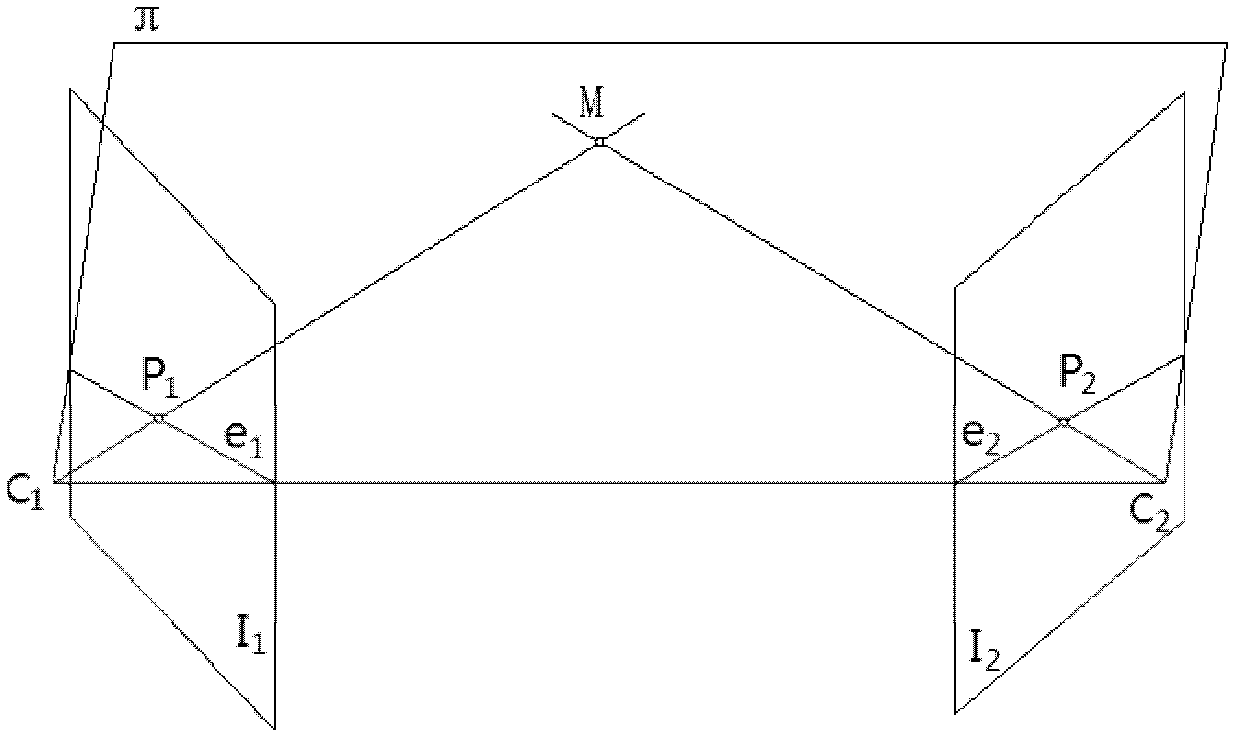

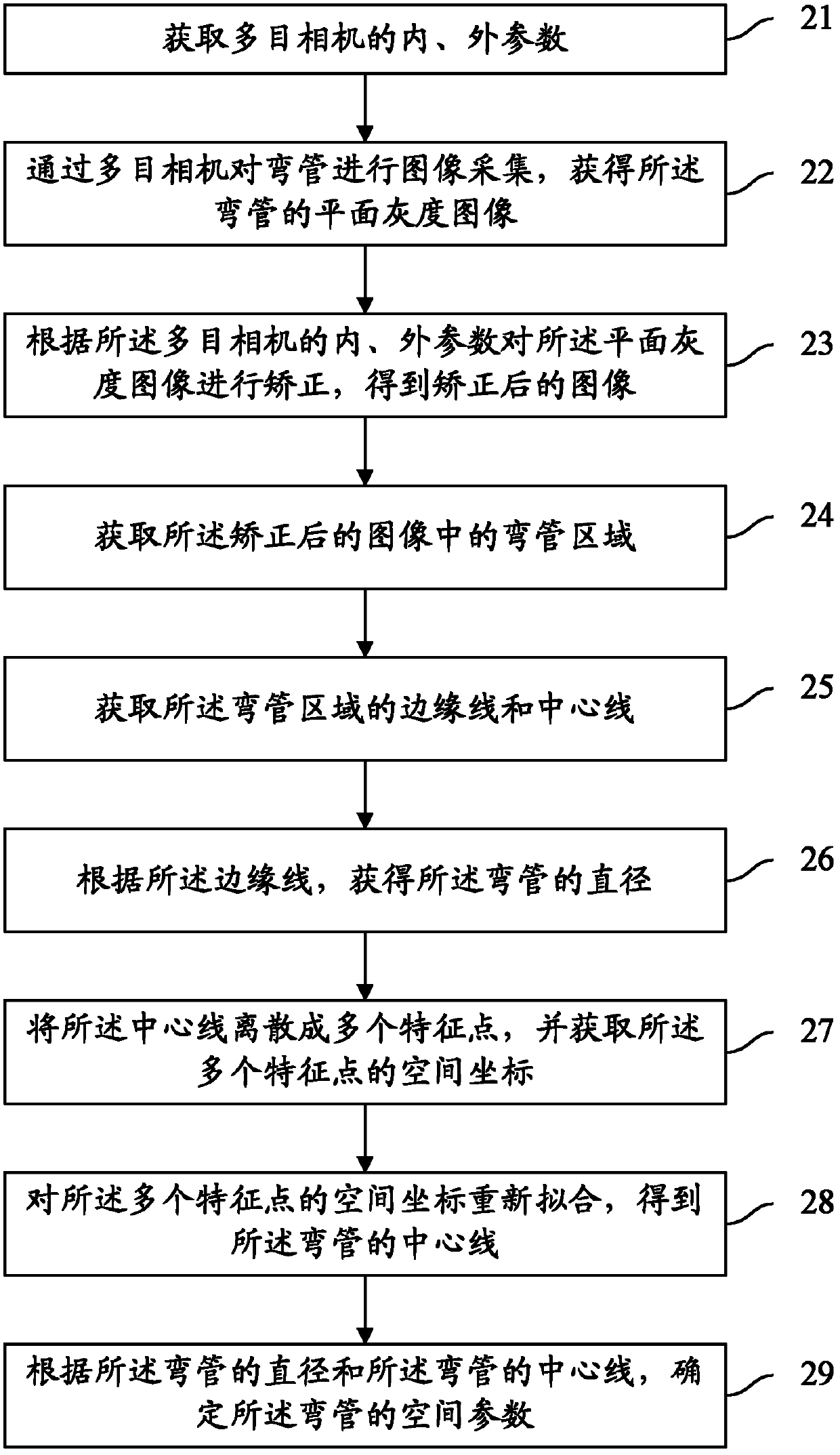

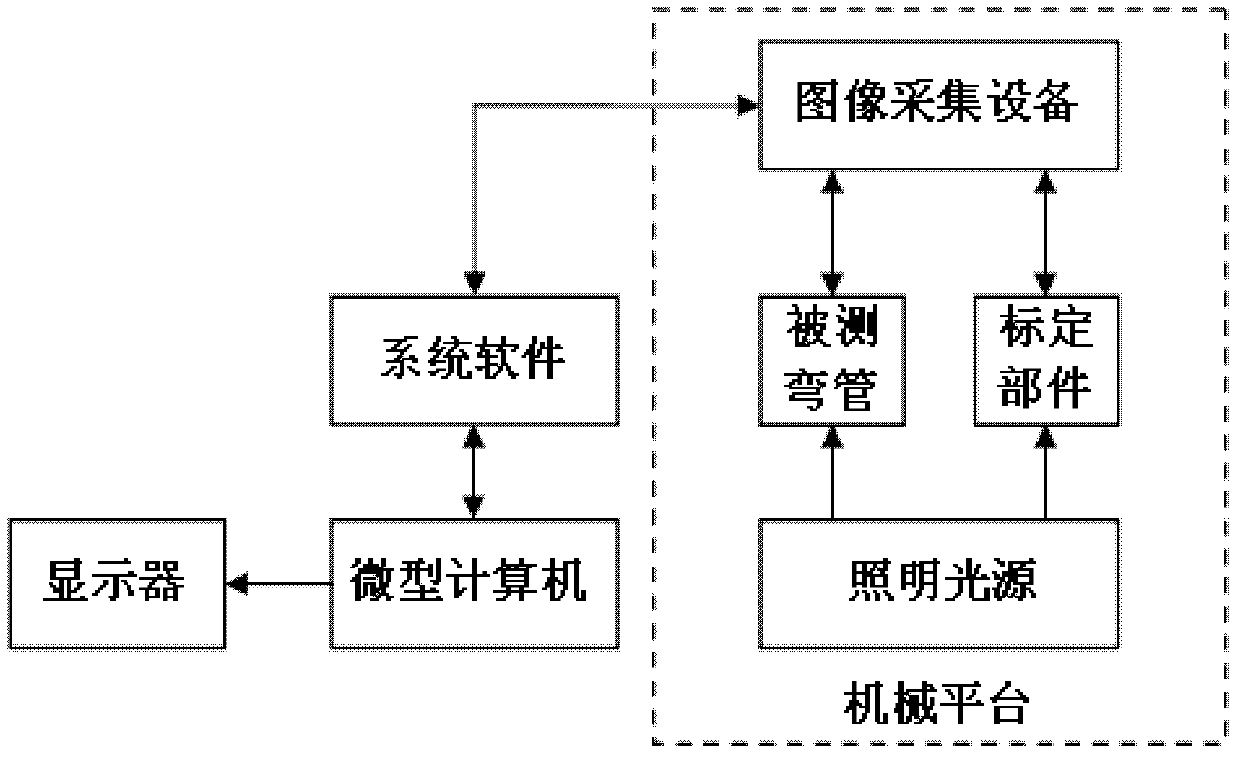

[0061] The present invention aims at the disadvantages of the existing contact bend pipe measurement method based on mechanical devices and the non-contact bend pipe measurement method based on laser CCD technology, which are cumbersome and complicated in process, low in efficiency and high in cost, and the simple binocular vision scheme for measuring bends In order to solve the problem of incomplete space pose information of pipes, a method and system for measuring bend pipe parameters based on multi-eye vision is provided, so that the complete space pose of bend pipes can be quickly measured by using multi-eye vision technology. The space pose measurement of the bend includes the pose of the bend and the diameter of the bend. The pose of the bend refer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com