Acoustic monitoring and location method for furnace tube leakage and device thereof

A positioning device and acoustic technology, applied in the direction of detecting the appearance of fluid at the leak point, indicating the working condition of the boiler, using liquid/vacuum for liquid tightness measurement, etc. Pipe leakage acoustic monitoring and other issues to achieve the effect of maintaining accuracy and improving positioning accuracy

Inactive Publication Date: 2012-04-11

NORTH CHINA ELECTRIC POWER UNIV (BAODING)

View PDF7 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the shortcomings of the existing leakage measurement method mentioned in the above background technology, such as low precision and inability to monitor online, the present invention proposes a furnace tube leakage acoustic monitoring and positioning method and device

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example 1

[0079] Example 1: When the delay error is 0 milliseconds, the positioning result is (3.0000, 2.0000, 3.0000)

example 2

[0080] Example 2: When the delay error is 1 millisecond, the positioning result is (2.7741, 2.1160, 2.8072)

example 3

[0081] Example 3: When the delay error is 0.1 milliseconds, the positioning result is (2.9752, 1.9964, 3.0372)

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

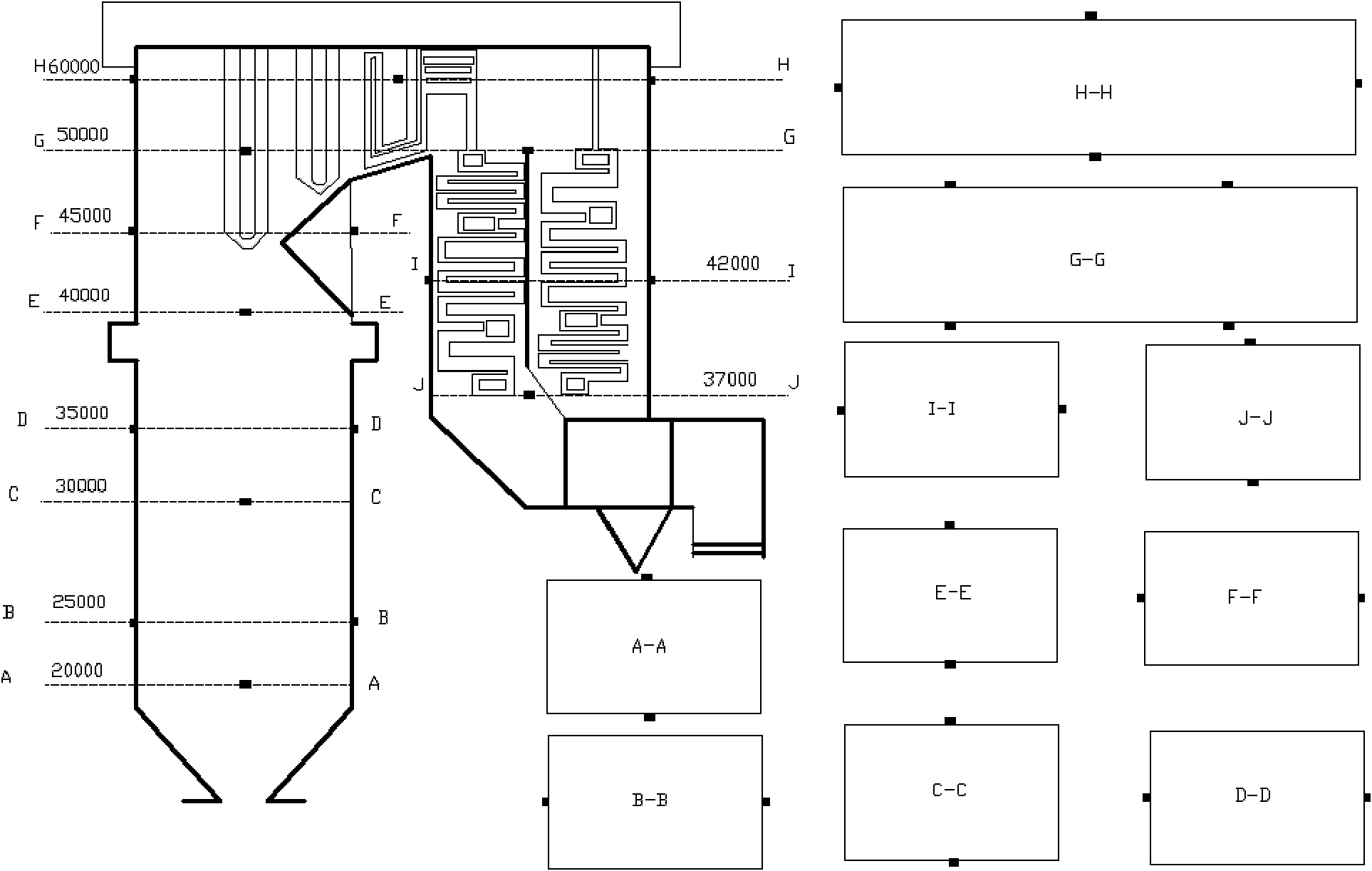

The invention discloses an acoustic monitoring and location method for furnace tube leakage and a device thereof in the technical field of leakage location method in the boiler furnace. The invention can obtain hyperboloid equations of the leakage signal by measuring with a sensor; then the sensor having largest measured sound pressure level is selected as the reference sensor, so as to obtain the coordinate values of other sensors; then the leakage signal is filtered, and the time delay estimated values of other sensors and the reference sensor are obtained; finally, according to the coordinate value of each sensor, the CHAN algorithm is used for optimizing the hyperboloid equations, so as to further obtain the coordinate of the leakage point. The invention can select the reference sensor by the method of measuring sound pressure level, so as to avoid the problem that the negative time delay value of the theoretical values cannot be realized in actual measurement; three-dimensional location technology is adopted, the location accuracy is improved and the online monitoring and location are realized.

Description

technical field [0001] The invention belongs to the technical field of leakage positioning in a boiler furnace, and in particular relates to a furnace tube leakage acoustic monitoring and positioning method and device. Background technique [0002] Furnace pipe leakage of thermal power plant boilers seriously endangers the safe and economical operation of the power station. Existing technologies have been able to detect the leakage online when the furnace bursts, but most of them cannot be accurately located. The monitoring technology in patents US496079 and CN2253829 adopts the method of arranging a large number of measuring points on the wall of the furnace, which can only provide a rough positioning with the measuring points as the center and a radius of 10 meters. The patent CN101799533A has poor positioning accuracy and poor anti-disturbance ability. The algorithm in the patent CN101813545A requires a long iterative running time, and there are still accuracy problems, a...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F22B37/38G01M3/24

Inventor 安连锁沈国清冯强张世平王鹏

Owner NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com