Method for coating films on focusing mirrors

A mirror and magnetron sputtering technology, applied in sputtering coating, ion implantation coating, vacuum evaporation coating, etc., to achieve the effect of eliminating uneven film thickness, easy control of deposition process, and high coating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

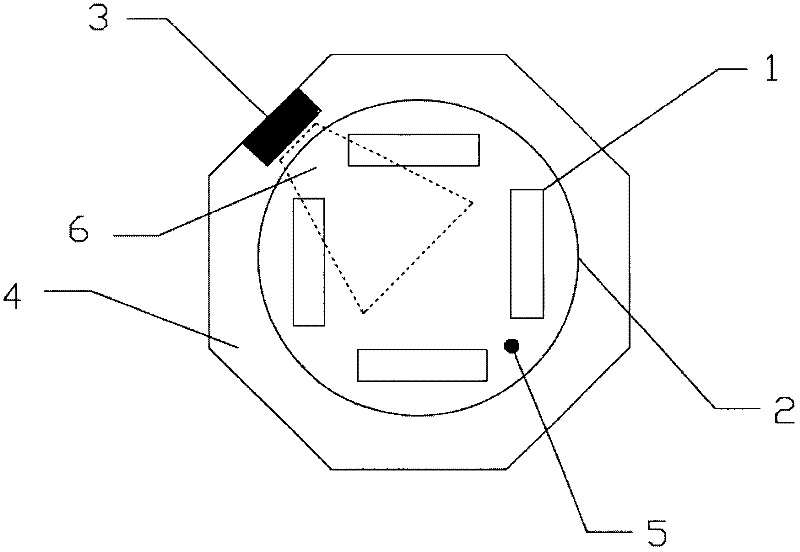

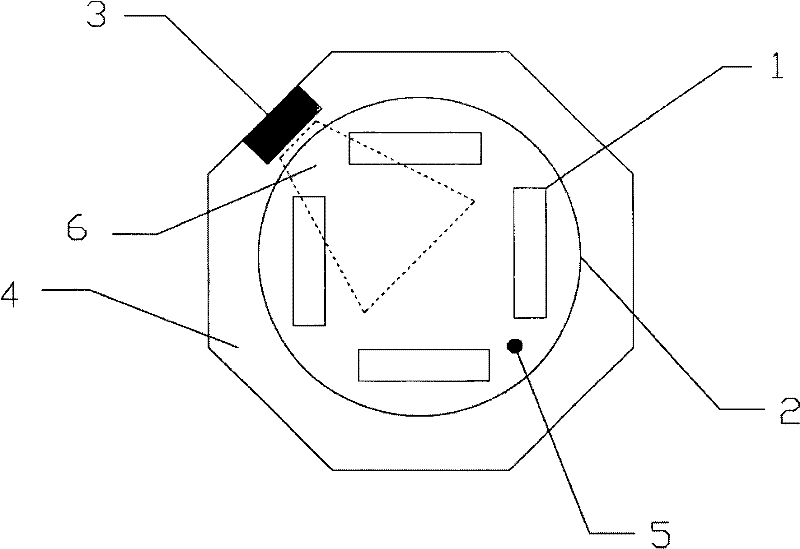

[0021] A kind of coating method of focusing reflector of the present embodiment, such as figure 2 shown, including the following steps:

[0022] Step 1: Place four focusing mirrors 1 to be coated evenly on a horizontal turntable 2, the turntable 2 is located in a vacuum chamber 4 with a magnetron sputtering target 3 on an inner wall, and the focusing mirror 1 is surrounded by The center of the formed regular polygon coincides with the center of circle of the turntable 2 to ensure that the coating surface of each focusing mirror 1 is parallel to the target surface of the magnetron sputtering target 3 and the distance is equal; select Ti or TiO 2 The coating material is used as the target;

[0023] Step 2: mark a position indicator mark 5 on the turntable 2 of step 1, and make the position indicator mark 5 be in an initial position before the coating starts;

[0024] Step 3: Seal the vacuum chamber 4, start the vacuum acquisition system, and the vacuum degree in the vacuum ch...

Embodiment 2

[0031] The method of this embodiment is similar to that of Embodiment 1, except that the target material of the magnetron sputtering target is Si or SiO 2 , so no more details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com