Latitudinal lap-seam rubber dam bag and production technology method thereof

A rubber dam bag and production process technology, which is applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of uneven thickness of rubber dam bags, many lap seams of rubber dam bags, and poor integrity of resistance to upstream water thrust, etc. Achieve the effects of reducing the length of seams, shortening the production cycle, and reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

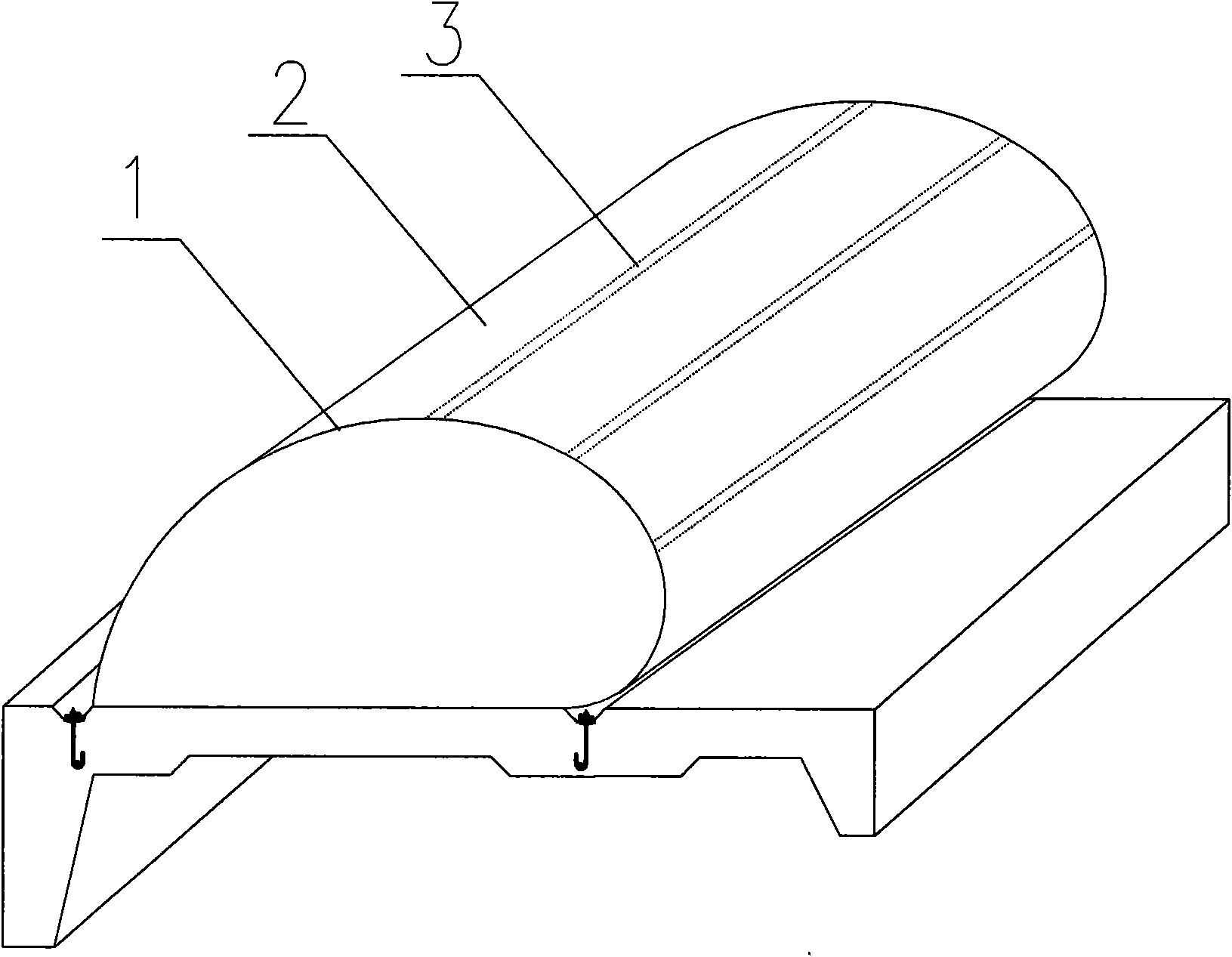

[0015] The adhesive tape 2 made by coating the inner covering rubber layer, the outer covering rubber layer and the intermediate adhesive layer on the stressed skeleton material of 2~3 layers of nylon is cut according to the latitudinal length of the rubber dam 1 to be produced, and the length of the adhesive tape 2 is The width is not limited, generally according to the original width of the skeleton material; the tape 2 is lapped along the width direction, and the seam 3 is in the latitudinal direction of the rubber dam, until the width of the perimeter dimension of the rubber dam section is obtained, and the rubber dam can be obtained Bag finished.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com