Preparation method of erythromycin thiocyanate

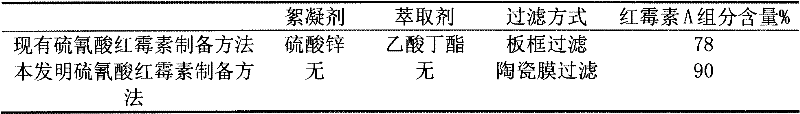

A technology of erythromycin thiocyanate and erythromycin, which is applied in the field of medicine and biology, can solve the problems of unfavorable environmental protection and operation safety, large demand for organic solvents, large solvent consumption, etc., and achieve environmental protection and production safety , Reduce the generation of waste residue and reduce the use of organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: the preparation of erythromycin fermented liquid

[0048] (1) Concentration of fermented liquid: After removing slag from erythromycin fermented liquid, adjust the pH to 8.0-8.4 with a 10% sodium hydroxide solution, filter through a ceramic membrane with a pore size of 50nm-100nm, and filter the filtrate with 200 molecular weight nano Concentrate through the filter membrane to obtain a concentrated solution of erythromycin.

[0049] (2) Recrystallization: place the erythromycin concentrate in a crystallization tank, add 10% sodium thiocyanate solution (add 0.18kg of 10% sodium thiocyanate solution per billion units of erythromycin), use 50% The glacial acetic acid solution adjusts the pH to be 6.0~6.5, crystallizes out erythromycin thiocyanate, and the solid-liquid mixture is centrifuged to obtain the crude product of erythromycin thiocyanate, and the crude product of erythromycin thiocyanate is added into acetone according to the ratio of 1:4, Use a 10% ...

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of erythromycin thiocyanate

[0056] (1) Concentration of fermented liquid: After removing slag from erythromycin fermented liquid, adjust the pH to 7.8-8.2 with a 15% sodium hydroxide solution, filter through a ceramic membrane with a pore size of 50nm-100nm, and filter the filtrate with a 200-molecular-weight nanometer Concentrate through the filter membrane to obtain a concentrated solution of erythromycin.

[0057] (2) Recrystallization: place the erythromycin concentrate in a crystallization tank, add 15% sodium thiocyanate solution (add 0.15kg of 15% sodium thiocyanate solution per billion units of erythromycin), use 40% The glacial acetic acid solution adjusts the pH to be 6.0~6.5, crystallizes out erythromycin thiocyanate, and the solid-liquid mixture is centrifuged to obtain the crude product of erythromycin thiocyanate, and the crude product of erythromycin thiocyanate is added into acetone according to the ratio of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com