A method for extracting 3-nitro-4-hydroxyphenylarsineic acid from waste water

A technology for hydroxyphenylarsinic acid and waste water, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as excessive solid precipitation and cost increase, and achieve low energy consumption , low raw material input, less loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

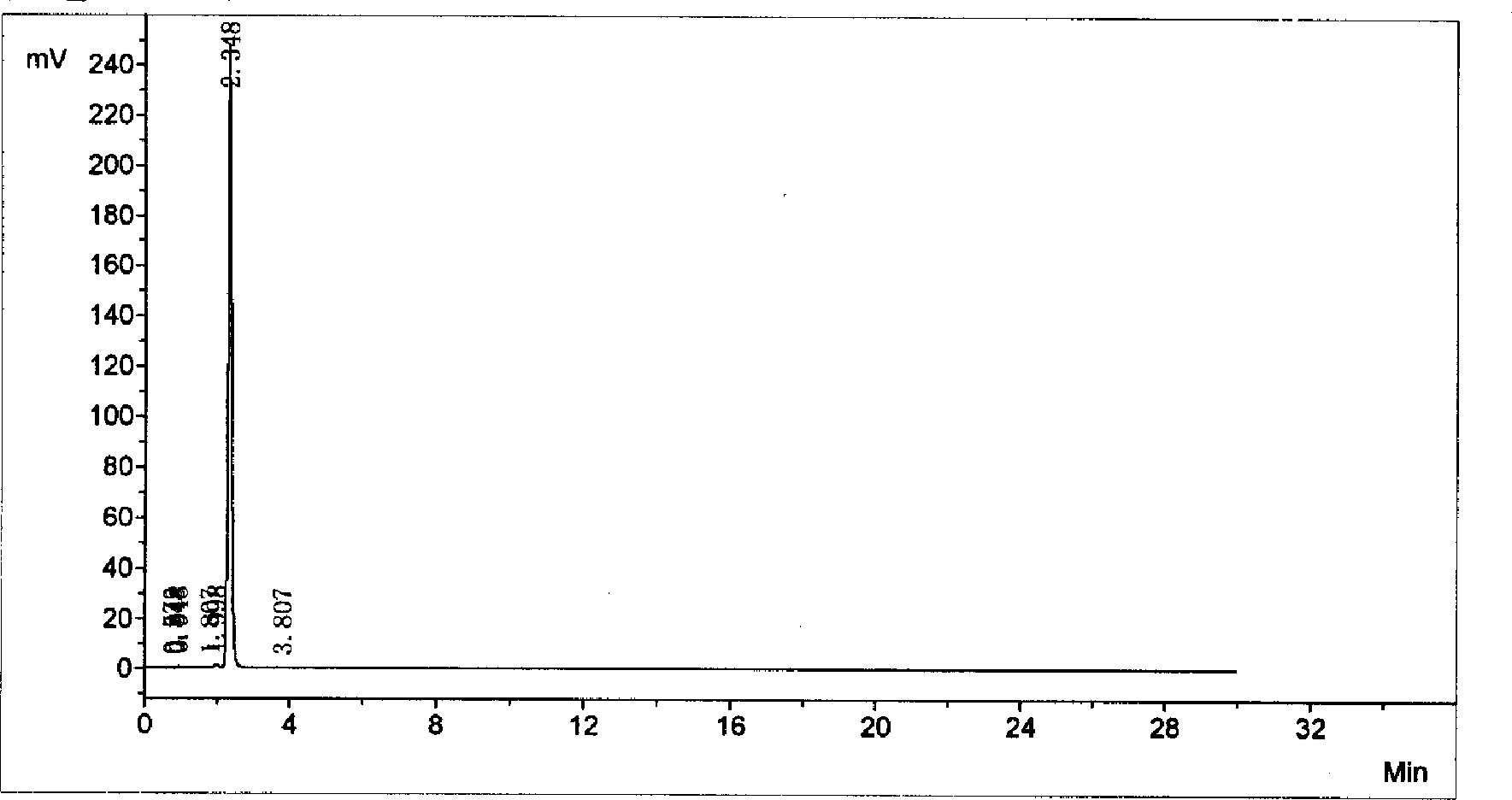

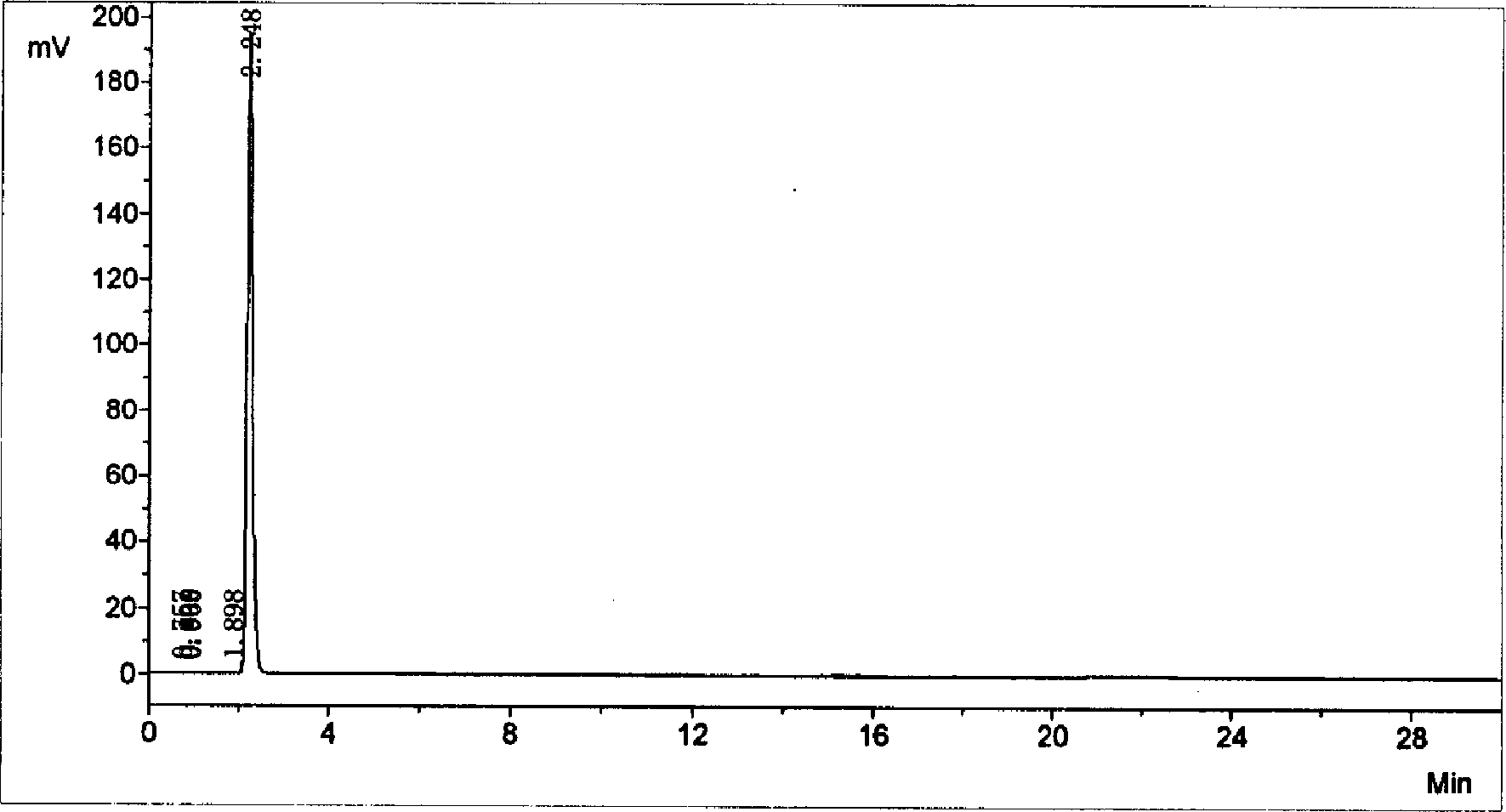

[0043] (1) Add 100mL of waste water containing roxarsone (ROX%=1.18%, pH=2.5), 50mL of butyl acetate, and 100mL of tert-butylamine into a 250mL Erlenmeyer flask in sequence, stir for 5min, and transfer to 250mL liquid separation at a temperature of 25°C Let stand in the funnel for 15min to obtain a water layer (lower layer), an organic solvent layer (butyl acetate layer, upper layer) and an extractant layer (tert-butylamine layer, middle layer), and analyze the water layer by HPLC, and the result ROX%=0.20 %, the removal rate is 83.0%; the primary water layer discharges up to the standard.

Embodiment 2

[0045] (1) Add 100mL of waste water containing roxarsone (ROX%=1.18%, pH=2.5), n-octanol 10mL, and trioctylamine 2.5mL into a 250mL Erlenmeyer flask successively, stir for 5min, and turn the temperature to 30°C. Put into a 250mL separatory funnel and let stand for 15min to obtain a water layer (lower layer), an organic solvent layer (n-octanol layer, upper layer) and an extractant layer (trioctylamine layer, middle layer), and analyze the water layer by HPLC , result: ROX%=0.072%, removal rate 93.9%.

[0046] (2) Add 4mL industrial saturated concentrated hydrochloric acid to 97mL primary water layer to adjust pH=0.5, the total volume is 101mL, pour it into a 250mL Erlenmeyer flask, add 50.5mL n-octanol, add 101mL trioctylamine, stir for 5min, temperature 30 ℃, transfer to a 250mL separatory funnel and let stand for 15min to obtain a secondary water layer (lower layer), a secondary organic solvent layer (n-octanol layer, upper layer) and a secondary extractant layer (trioctylam...

Embodiment 3

[0048] (1) Add 400mL of waste water containing roxarsone (ROX%=0.6%, pH=2.5), 40mL of n-hexane, and 20mL of cyclohexylamine into a 500mL Erlenmeyer flask in turn, stir for 5min, and transfer to a 500mL portion at a temperature of 25°C. Let stand in the liquid funnel for 15min to obtain a water layer (lower layer), an organic solvent layer (n-hexane layer, upper layer) and an extractant layer (cyclohexylamine layer, middle layer), and analyze the water layer by HPLC, the result: ROX %=0.055%, removal rate 90.8%.

[0049] (2) Add 4 mL of industrial saturated concentrated hydrochloric acid to the 390 mL primary water layer to adjust the pH to 0.5. The total volume is 394 mL, pour it into a 500 mL conical flask, add 40 mL of n-hexane, add 20 mL of cyclohexylamine, stir for 5 min, and the temperature is 25 ° C. Transfer to a 500mL separatory funnel and let stand for 15min to obtain a secondary water layer (lower layer), a secondary organic solvent layer (n-hexane layer, upper layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com