Pesticide composition of flubendiamide and neonicotinoid insecticide

A technology for nicotinic insecticides and pesticide compositions, which is applied in the field of pesticide formulations, can solve the problems of no systemic effect, no ovicidal effect, limited application, etc., and achieves the expansion of the insecticidal spectrum, the improvement of drug efficacy, and the sustained effect. long term effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] 1. Firstly, the preparation of the insecticidal and antiviral composition is described.

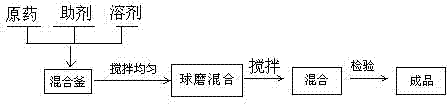

[0026] This product is composed of active ingredients, additives, and solvents. The original drug, wetting agent, dispersant, anticoagulant, and solvent are mixed in a mixing kettle, and then the mixture is pumped into a sand mill for sanding. Grinding, after the active ingredient is sand-milled to a particle size of about 5 μm, it is pumped into the mixer again for mixing. The wetting agent, dispersant, defoamer, anticoagulant, etc. added in this patent can keep the stability of the preparation at high temperature and low temperature, help storage and transportation, and ensure the efficacy of the drug.

[0027] The invention is illustrated by the following examples without limiting the invention.

Embodiment 1

[0028] Example 1 31% flubendiamide imidacloprid suspension concentrate (30:1)

[0029] 545 grams of deionized water are pumped into the stirring tank, 40 grams of sodium lignosulfonate, 20 grams of sodium lauryl sulfate and 5 grams of formaldehyde, 50 grams of ethylene glycol are drawn into the stirring tank, and then 300 grams of 1 g of flubendiamide, 10 g of imidacloprid, and 30 g of white carbon black were put into the shear tank in sequence, and the materials were mixed evenly by shearing for 30 minutes. Turn on the circulating water, ball mill the material at a certain flow rate, control the temperature below 40 degrees, and pass the fineness through a 325 mesh sieve to obtain 31% flubendiamide imidacloprid suspension concentrate.

Embodiment 2

[0030] Example 2 21% flubendiamide·clothianidin suspension concentrate (20:1)

[0031] 660 grams of deionized water are pumped into the stirring tank, 50 grams of dispersant NNO, 40 grams of diffusion agent MF, 20 grams of sodium lauryl sulfate and 5 grams of formaldehyde, 20 grams of ethylene glycol are drawn into the stirring tank, and then While stirring, put 200 grams of flubendiamide, 10 grams of clothianidin, and 5 grams of kaolin into the shear tank in sequence, and shear for 30 minutes to mix the materials evenly. Turn on the circulating water, ball mill the material at a certain flow rate, control the temperature below 40 degrees, and pass the fineness through a 325 mesh sieve to obtain 21% flubendiamide clothianidin suspension concentrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com