Optimized control method for milling process in cement plant

A process optimization and control method technology, applied in the direction of adaptive control, general control system, control/regulation system, etc., to achieve the effect of reasonable structure, convenient operation and stable fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

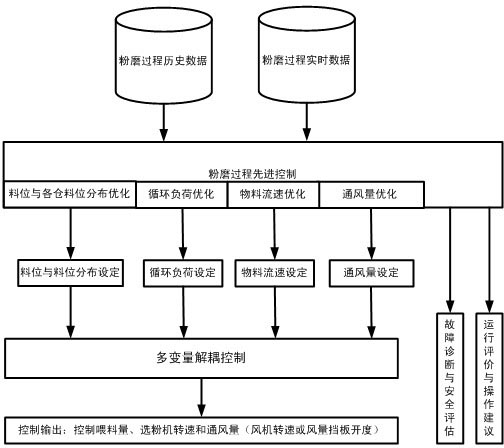

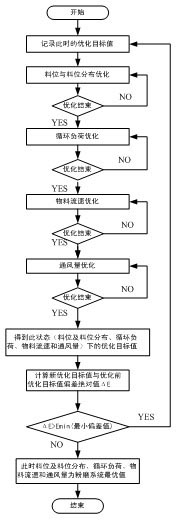

Method used

Image

Examples

Embodiment

[0060] The type of cement mill in a cement factory is a closed-circuit mill. The mill size is: 3.2m×13m, with two warehouses. The design output is 60t / h, the maximum ball loading capacity is 133 tons, and the grinding head is equipped with a roller crushing system. . The process flow of the grinding production process is as follows: the materials with a good ratio are transported to the 40t small silo at the front end of the roller press through the elevator, the materials are squeezed by the roller press and lifted to the breaker, and the broken materials There are two flow directions. The coarser materials are sent to the 40t small silo by the transmission equipment, and the suitable materials enter the grinding head silo, and are sent to the mill for grinding through the rotor quantitative feeding scale; the finished cement is coarsely powdered by the powder classifier. In the process of separation and dust removal, the finished products with qualified fineness are sent to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com