Medium frequency electric furnace mouth

A technology of intermediate frequency electric furnace and furnace nozzle, which is applied in the direction of furnace, furnace components, electric charge control, etc. It can solve the problems of small demand for molten metal, affect pouring quality, and lower temperature, so as to reduce the splash of molten metal, improve the efficiency of casting pipe, The effect of reducing temperature drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

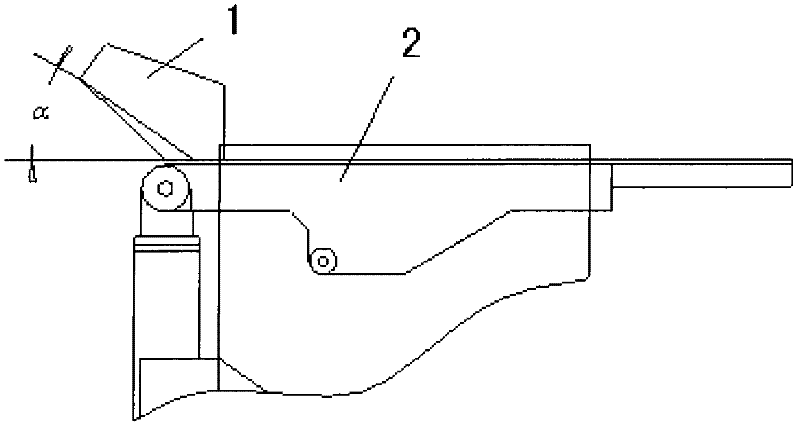

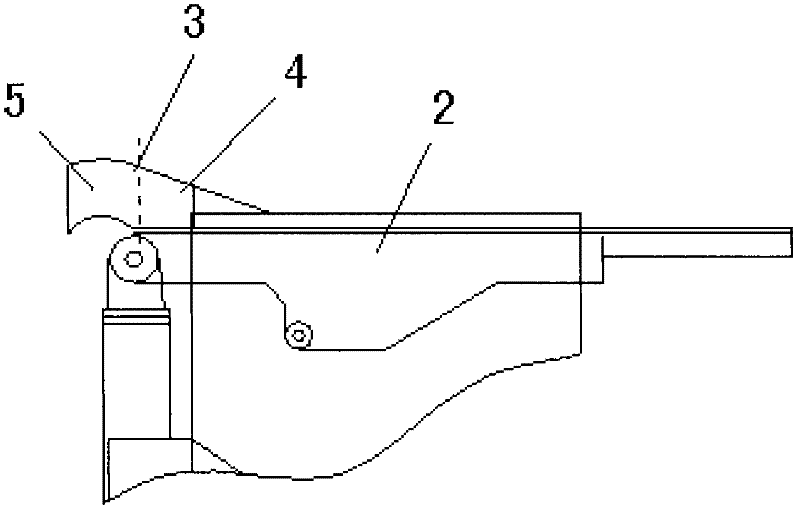

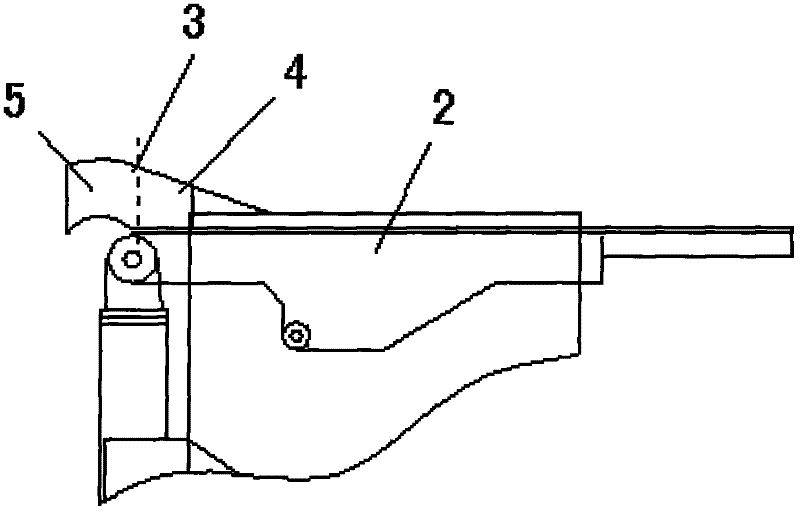

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0011] Such as figure 2 As shown, the present invention includes an electric furnace body 2 and an electric furnace nozzle 3 connected to the electric furnace body 2. The electric furnace nozzle 3 adopts an arc-shaped structure, and it is composed of a furnace nozzle connection end 4 and an outlet integrally formed with the furnace nozzle connection end 4. Liquid port 5 constitutes. The connecting end 4 of the furnace nozzle and the electric furnace body 2 are connected in an inclined manner, so that the area of the connecting end 4 of the furnace nozzle is increased, and the molten metal in the electric furnace body 2 can be poured out in a larger amount.

[0012] In the above-mentioned embodiment, the liquid outlet 5 of the circuit furnace nozzle 3 adopts a circular arc surface, so that when the electric furnace body 2 dumps the molten metal, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com