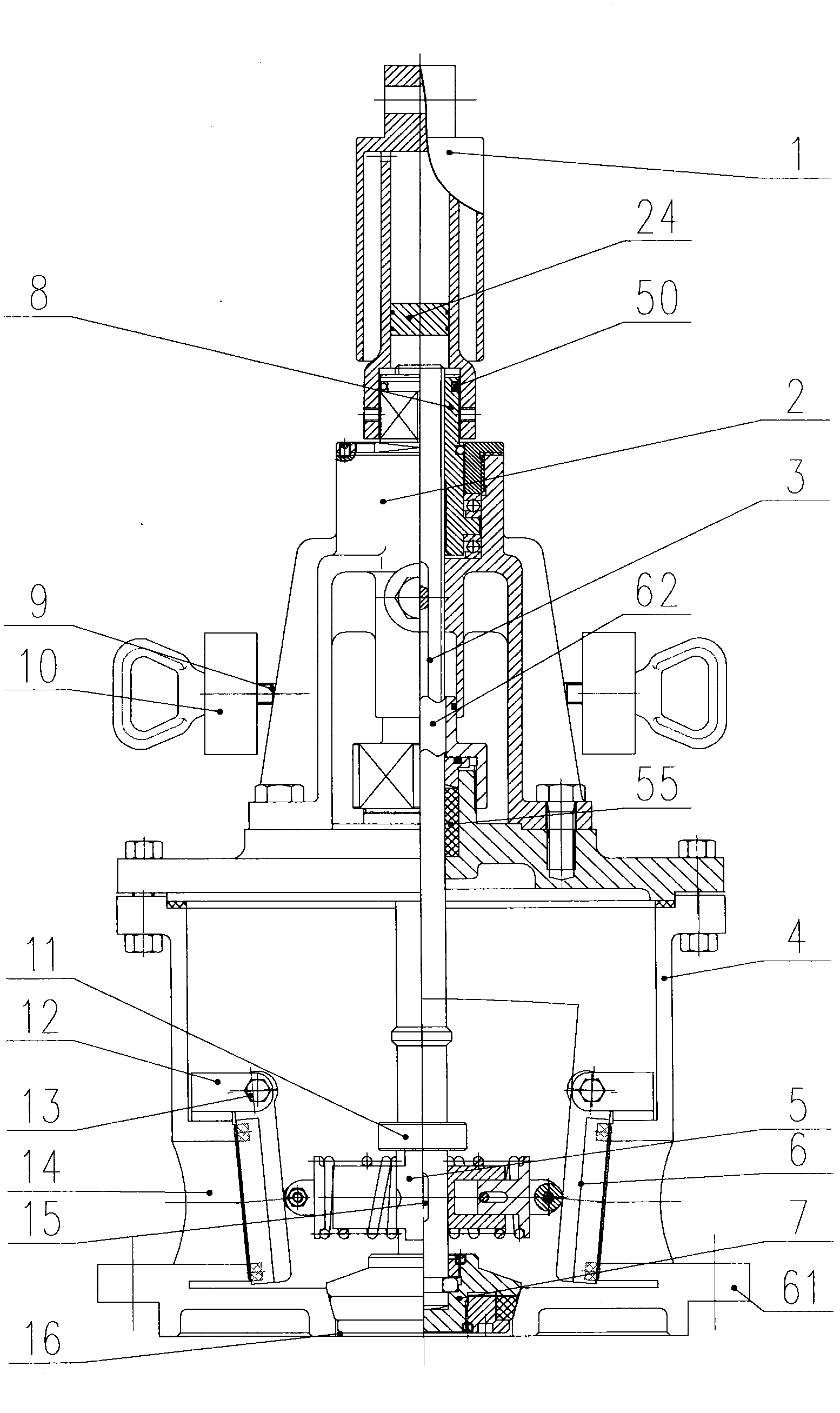

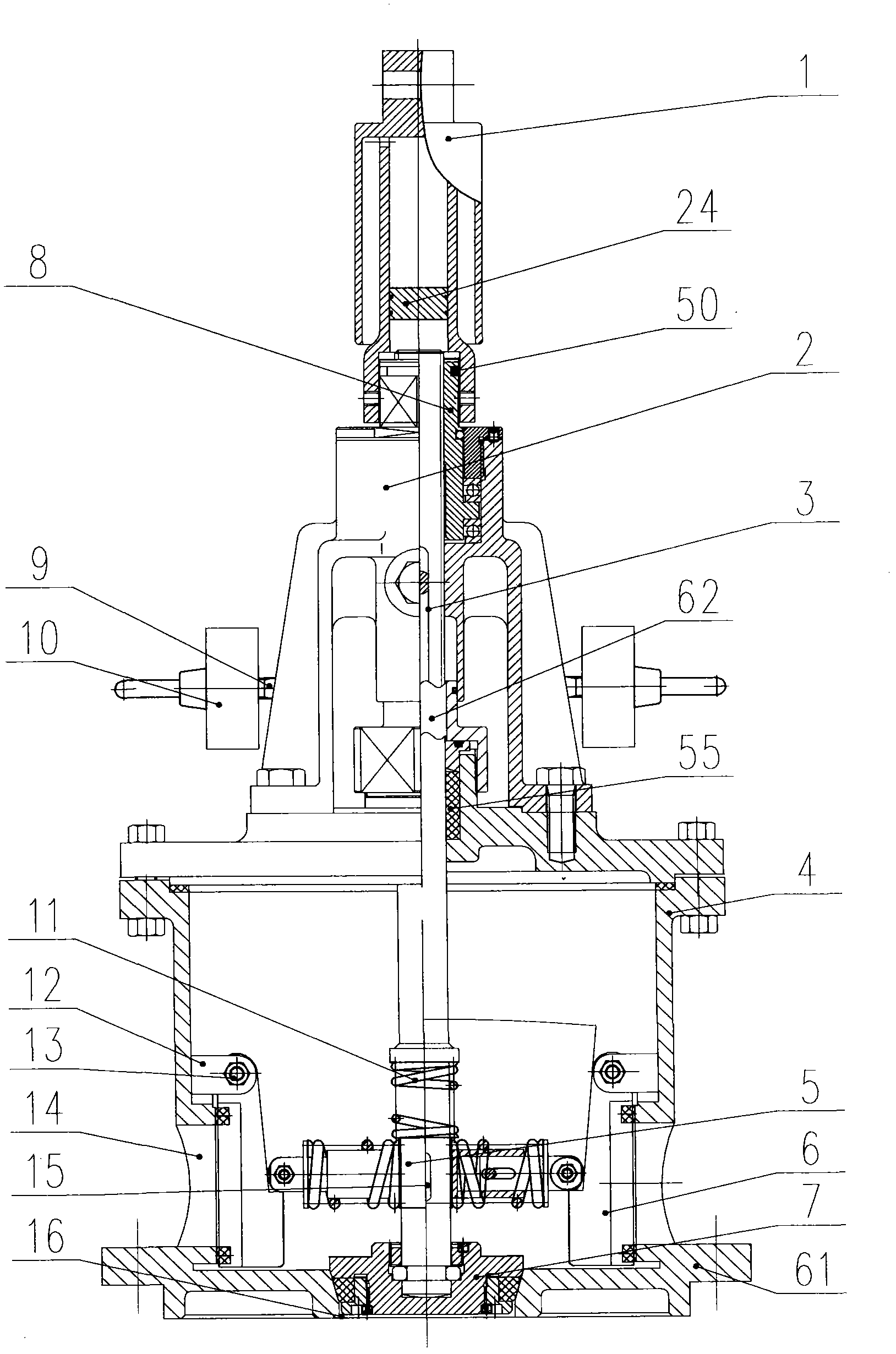

Safety discharge valve

A technology of safe discharge and valve stem, applied in the direction of safety valve, lift valve, multi-way valve, etc., can solve the problem that the valve cannot be closed, the sealing failure of the side valve plate and the side water inlet, the bottom valve disc cannot be closed with the valve bottom port, etc. problem, to achieve the effect of reliable security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

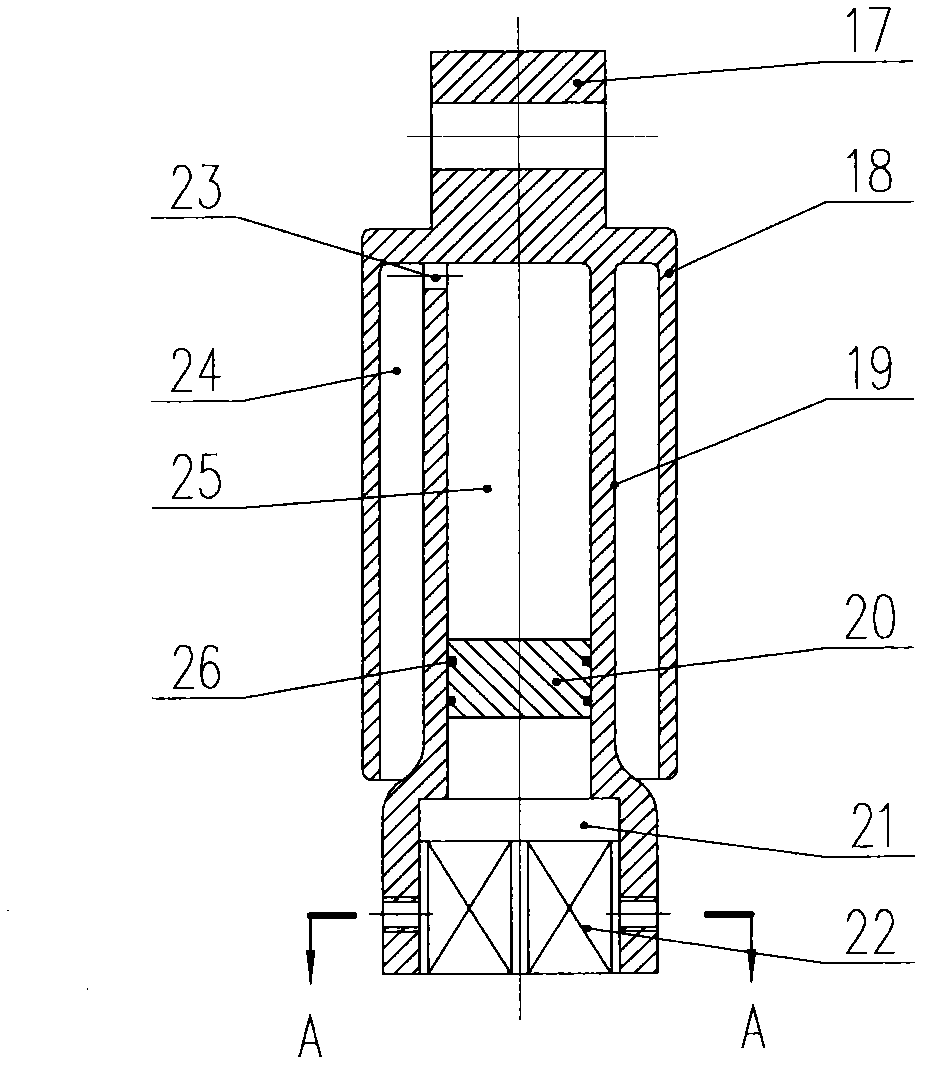

Embodiment 2

[0051] Embodiment 2, its working principle is the same as that of Embodiment 1, the difference is that the front sealing surface of the side rotary sealing plate in Embodiment 1 is parallel to the back smooth contact surface, and the 5° included angle between the back smooth contact surface and the central axis of the valve stem is determined by The sealing surface of the side water inlet is inclined to form an included angle of 5° with the central axis of the valve stem. The fixed pressure part at the upper end of the elastically expandable side capping pressure assembly is the protruding pillar of the valve stem body. The sealing surface of the side water inlet in Example 2 Parallel to the central axis of the valve stem, the 5° included angle between the back smooth contact surface of the side rotary sealing plate and the central axis of the valve stem is realized by the 5° included angle between the back smooth contact surface of the side rotary sealing plate and the front se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com