Drawer self-locking mechanism of tool box cabinet

A technology of drawers and cabinets, which is applied in building locks, building structures, buildings, etc., can solve problems such as insecurity, and achieve reliable self-locking and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

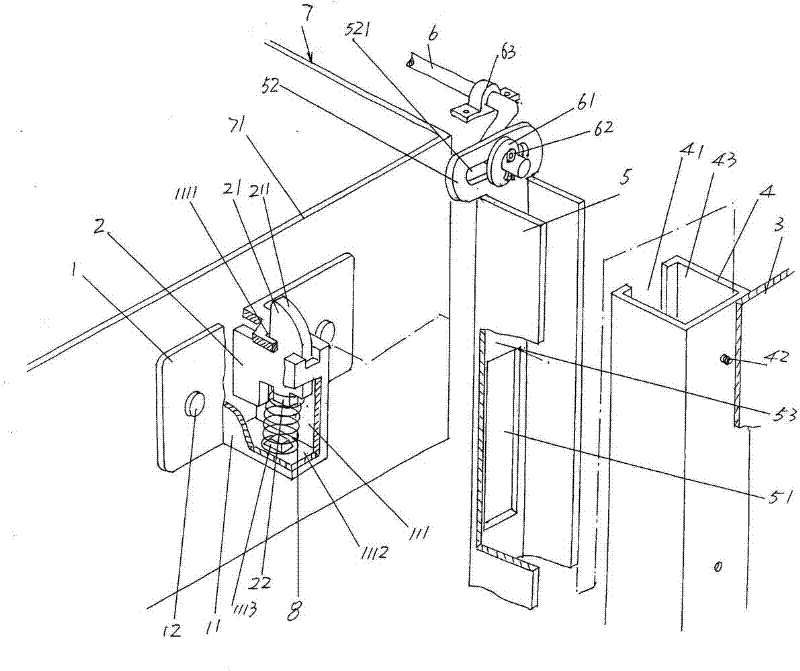

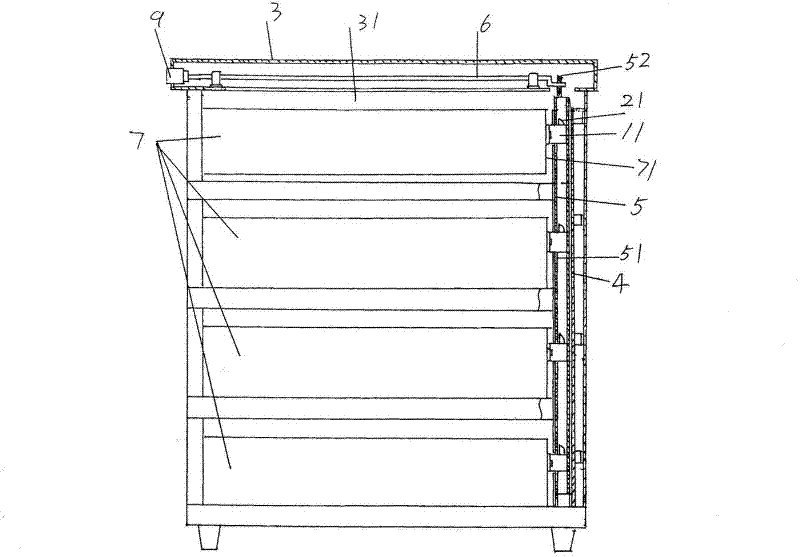

[0020] please see figure 1 , shows the box body 3 of toolbox cabinet, on this box body 3 and towards the side of the drawer 7 that also mentions below is fixed with a guide rail tube 4 with fixing screw 42, and the height direction of guide rail tube 4 has guide rail tube cavity 43, and on the side of the guide rail tube 4 towards the drawer 7, a groove chamber 41 communicating with the guide rail tube cavity 43 is provided.

[0021] A lock bar 5 with a door-shaped cross section is slidably accommodated in the guide rail lumen 43 of the guide rail tube 4 , and a lock plate hook hole 51 is opened on the lock bar 5 and also faces the side of the drawer 7 . According to common knowledge, on a box body 3, can be configured from top to bottom or bottom to top, for example by a plurality of figure 2 The schematically illustrated four drawers 7 therefore have locking plate hook holes 51 corresponding to the respective drawers 7 on the locking bar 5 . A chute plate 52 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com