Gravity geotextile pipe mud grouting device

A geotechnical pipe and mud filling technology, applied in river regulation, coastline protection and other directions, can solve the problems of high production cost, accelerated sediment settlement, weak embankment protection force, etc., to achieve high mud filling efficiency and prevent displacement. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

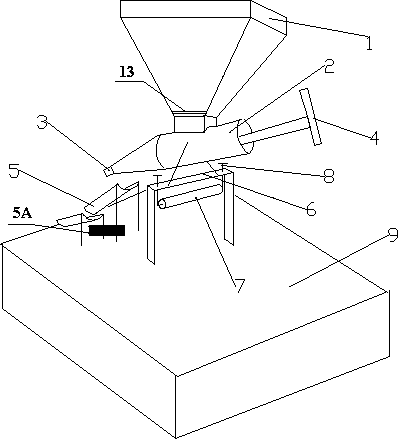

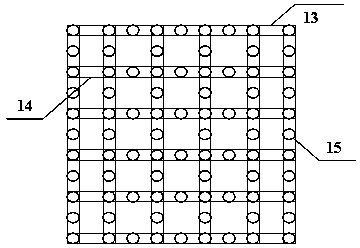

[0042] This embodiment combines the attached Figures 1 to 3 Describe the structure and structural relationship of the gravity geotechnical pipe grouting device of the present invention.

[0043] The gravity geotube grouting device of the present invention is mainly composed of a mud bucket 1, a mud filling box 2, a mud outlet 3, a geotube guide groove 5 and a geotube holder; the mud bucket 1 is arranged in the mud filling box 2, and communicate with the mud filling box 2 up and down, and one side opening of the mud filling box 2 is connected to the mud outlet 3; the mud filling box 2 is a piston-type pressurizable box; There is a geotechnical pipe guide groove 5; the geotechnical pipe holder is arranged at the intersection of the lower part of the mud filling box 2 and the uppermost end of the geotechnical pipe guide groove 5.

[0044] Wherein, the gravity geotube grouting device of the present invention also includes a floating platform 9, which is arranged at the bottom of...

Embodiment 2

[0053] This embodiment illustrates a method for grouting a geotechnical pipe using the gravity geotechnical pipe grouting device of the present invention, including the following steps:

[0054] 1) Geobag preparation

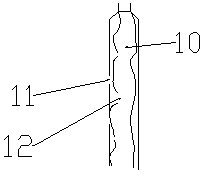

[0055] Double-layer geotechnical bags are set, the inner and outer geotechnical bags are flexible pipes, and the diameter of the inner layer geotechnical bag 10 is greater than or equal to the outer layer geotechnical bag 11, the outer layer geotechnical bag 11 and the inner layer geotechnical bag 10 are provided with mud inlet holes 12, and the inner layer geotechnical bag The openings of the bag 10 and the outer geotechnical bag 11 are arranged alternately.

[0056] Wherein, the hole distance on the inner layer geotechnical bag 10 or the outer layer geotechnical bag 11 is 0.4 to 2 meters.

[0057] 2) laying geotechnical pipes

[0058] After passing the geotechnical bag to be filled with mud through the geotechnical pipe holder, spread the end to be grouted c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com