Production method of glucose

A production method and glucose technology, applied in fermentation and other directions, can solve problems such as high steam consumption, large equipment jitter, poor operation stability of liquefier, etc., and achieve the effect of saving energy and reducing production and operation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

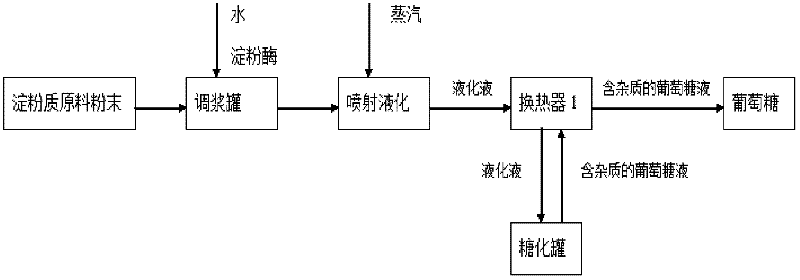

[0059] use figure 1 The process flow shown. Such as figure 1 As shown, 100 parts by weight of corn was crushed to obtain a crushed product with an average particle diameter of 400 microns, and the crushed product was mixed with 200 parts by weight of water at 50° C. to obtain a starch slurry. The starch slurry is fixed in the slurry tank, and an appropriate amount of calcium hydroxide is added to adjust the pH to 5.8-6.2.

[0060] At 50°C, uniformly mix the starch slurry with α-amylase in an amount of 18 enzyme activity units / g corn flour for 30 minutes to obtain a mixture, pump the mixture into the liquefaction injector, and spray it with steam at 145°C Spray contact (the weight ratio of steam to mixture is 0.06:1) was carried out in the container, and the contact time was 2 seconds, so that the temperature of the mixture after contacting with steam was 96° C., and kept for 130 minutes to obtain liquefied liquid.

[0061] Through a plate heat exchanger, the high-temperatur...

Embodiment 2

[0066] 100 parts by weight of corn were pulverized to obtain a pulverized product with an average particle diameter of 400 μm, and the pulverized product was mixed with 300 parts by weight of water at 55° C. to obtain a starch slurry. The starch slurry is constant in the slurry tank, and an appropriate amount of calcium hydroxide is added to adjust the pH to 5.8-6.0.

[0067] At 55°C, the starch slurry was uniformly mixed with α-amylase in an amount of 15 enzyme activity units / g corn flour for 30 minutes to obtain a mixture,

[0068] Add a set of heat exchange area of about 200m 2 The tube-and-tube heat exchanger, the liquefied liquid (after the liquefied liquid heats up the impurity-containing glucose solution, its own temperature is still maintained at about 85°C) goes through the tube side, and the mixture goes through the shell side, and the two are heated through the tube-and-tube heat exchanger. exchange.

[0069] Use a pump to pump the heat-exchanged mixture into th...

Embodiment 3

[0075] use figure 2 The process flow shown. Such as figure 2As shown, 100 parts by weight of corn was pulverized to obtain a pulverized product with an average particle diameter of 400 μm, and the pulverized product was mixed with 250 parts by weight of water at 53° C. to obtain a starch slurry. The starch slurry is fixed in the mixing tank, and an appropriate amount of calcium hydroxide is added to adjust the pH value.

[0076] The first part of amylase with 5 enzyme activity units / g corn flour was added before the starch slurry was heat-exchanged, and uniformly mixed at 53°C for 30 minutes to obtain a mixture; the second part of amylase with 5 enzyme activity units / g corn flour Add online after the mixture is sprayed, liquefied, flashed, and cooled. Before the above starch slurry is mixed with the first part of amylase, the pH of the starch slurry is adjusted to 5.8-6.0.

[0077] Add a set of heat exchange area of about 200m 2 The tube-and-tube heat exchanger, the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com