Car radial tire tread

A radial tire and tread technology, applied in the direction of tire tread/tread pattern, tire parts, vehicle parts, etc., can solve the problems of high fuel consumption and easy to fall off of lateral pattern, reduce rolling resistance and achieve good braking force , the effect of increasing the drainage space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

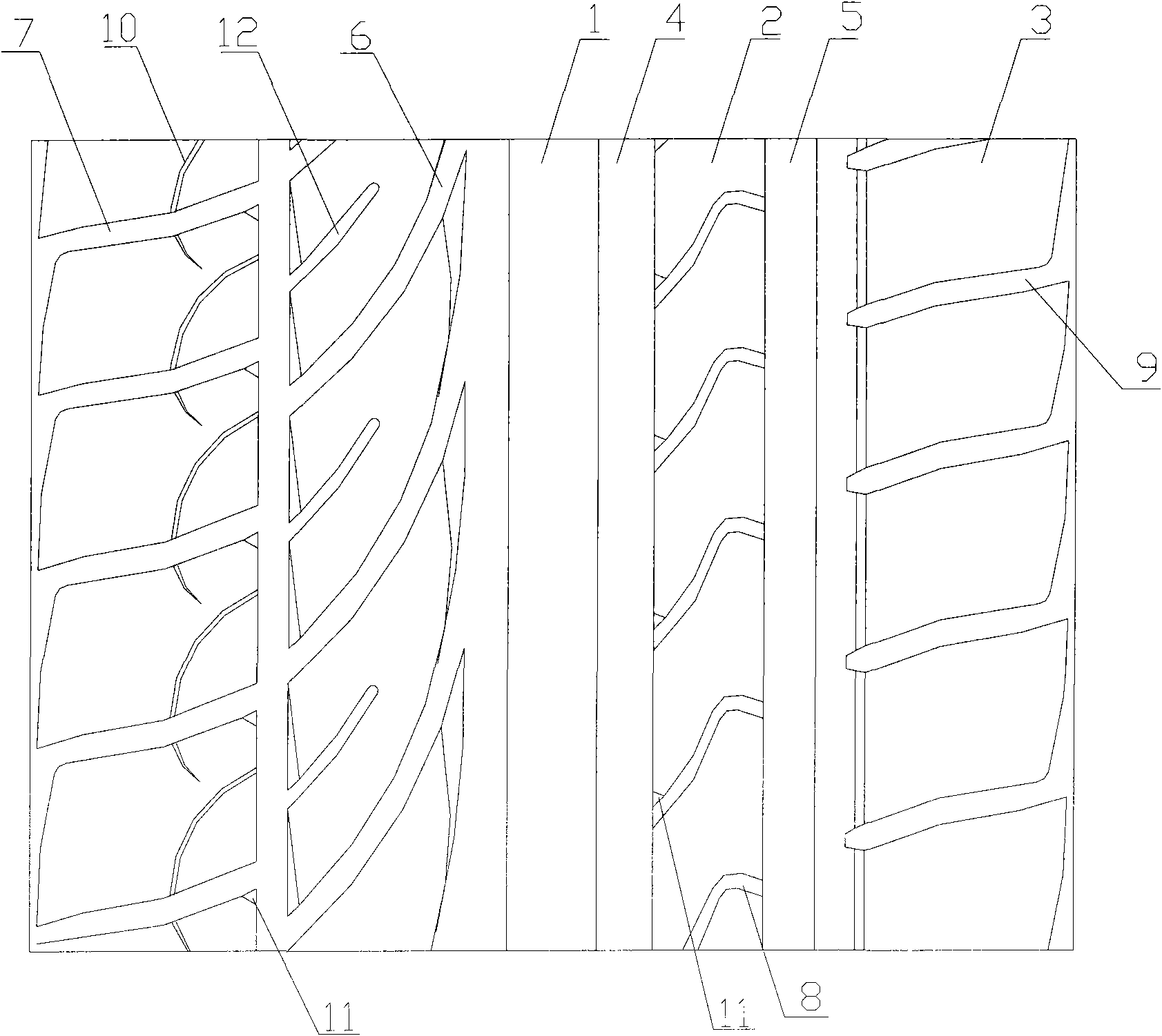

[0017] The tire tread of the present invention includes a central block 1, a side block 2, and a shoulder block 3. The central block 1 is located in the center of the tread. The left and right sides of the tire tread are arranged in order from the inside to the outside. , Shoulder block 3, central block 1 is a longitudinal integrated block, central block 1 and side blocks 2 are separated by main longitudinal circumferential grooves 4, side block 2 and shoulder block 3 Are separated by auxiliary longitudinal circumferential grooves 5; the adjacent blocks 2 on the left side of the central block 1 are separated by arcuate side grooves 6, and both ends of the arcuate side grooves 6 are connected to the main longitudinal direction. The circumferential groove 4 and the auxiliary longitudinal circumferential groove 5 are connected; the two adjacent shoulder blocks 3 on the left side of the central block 1 are separated by an arcuate shoulder groove 7, which is connected to the auxiliar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com