Device for measuring temperature of grinding area during plane grinding

A technology of temperature measurement and surface grinding, which is applied in the direction of measuring devices, grinding machine parts, thermometers, etc., can solve problems such as difficulty in achieving the best results, optimize surface grinding process parameters, and improve workpiece grinding surface quality and the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

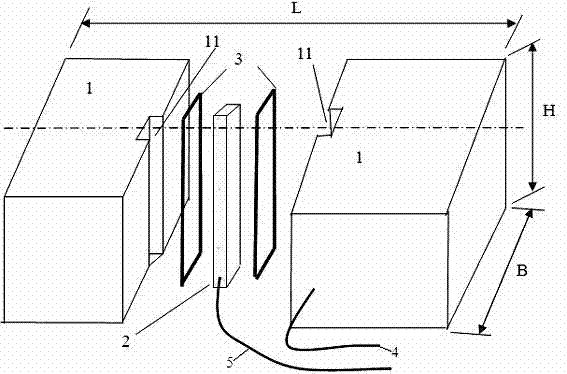

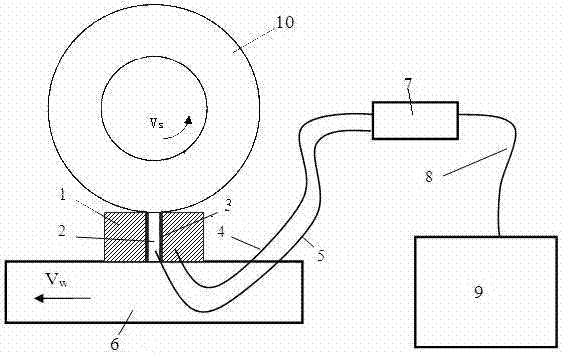

[0013] Such as figure 1 , figure 2 Shown, the grinding zone temperature measuring device of surface grinding of the present invention comprises constantan sheet 2, mica sheet 3, wire 4. Wire 5. Acquisition card 7, computer 9, etc.

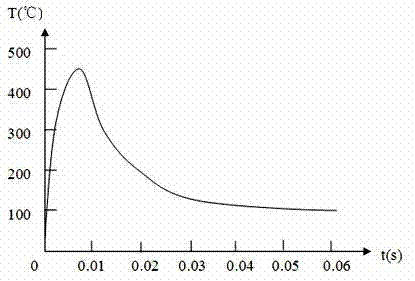

[0014] Such as figure 1 As shown, the measurement sensor part is made of wire 4 and wire 5 Connect the two ends of the conductor grinding workpiece 1 of different materials and the thermocouple material constantan sheet 2, and insulate the grinding workpiece (1) and the constantan sheet) with a mica sheet 3 . In the experimental grinding process, the wire was first 4 and wire 5. Insert the acquisition card 7 and the computer 9 with the cold junction compensation (CJC) function, and then set the speed of the grinding wheel 10 to be V s and table 6 speed is V w Carry out grinding experiment processing. Once th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com