Grinder

A grinding machine and grinding mechanism technology, applied in the direction of grinding machine tools, grinding devices, grinding tools, etc., can solve the problems of difficult observation of the working condition of the transmission mechanism, inconvenient disassembly and loading of the transmission mechanism, poor rigidity of self-lubricating bearings, etc., to achieve increased thickness , long service life and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

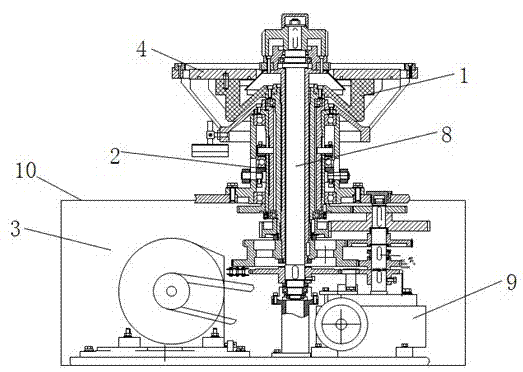

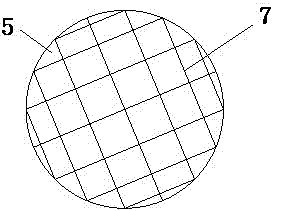

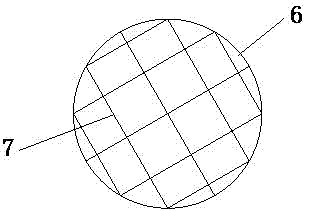

[0022] As shown in the figure, a grinding machine includes a grinding mechanism 1, a transmission mechanism 2 connected to the grinding mechanism 1, a driving mechanism 3 is connected below the transmission mechanism 2, and the grinding mechanism 1 includes an upper polishing sheet and a lower polishing plate. Polishing sheet 4, described upper polishing sheet is covered with upper grinding disc 5 below, and described lower polishing sheet 4 is covered with lower grinding disc 6, and all engrave imprint 7 on described upper grinding disc 5 and lower grinding disc 6, upper The imprint of the grinding disc 5 is 5-10mm deep, and the imprint of the lower grinding disc 6 is 4-10mm deep. The imprints on the upper grinding disc 5 and the lower grinding disc 6 all form a grid. The grid size is 10×10mm-20×20mm, the grid size on the lower grinding disc 6 is 15×15mm-30×30mm, and the transmission mechanism 2 includes a support rod 8 supporting the lower polishing sheet 4 and The operating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com