LED (light-emitting diode) luminous module and manufacturing method thereof

A light-emitting module and manufacturing method technology, applied in electrical components, electrical solid-state devices, circuits, etc., can solve the problems of dispersion, uneven refraction at the edge of the light spot, easy aging and deterioration of phosphors and packaging materials, and achieve uniform and good light color. Bukkake uniformity, simple connection circuit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

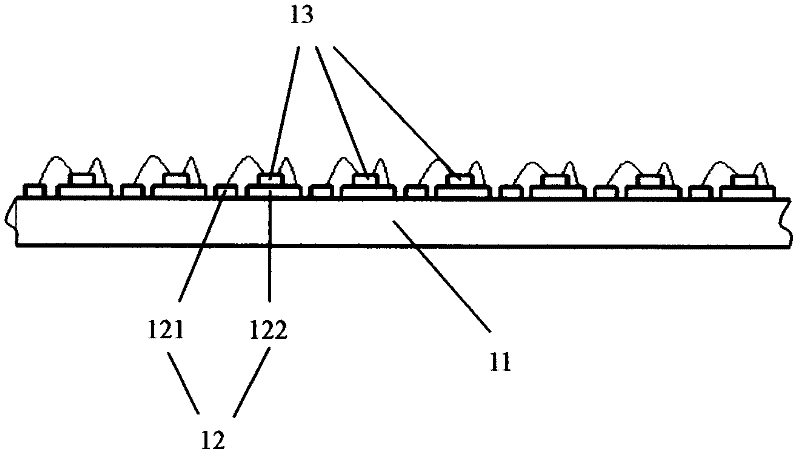

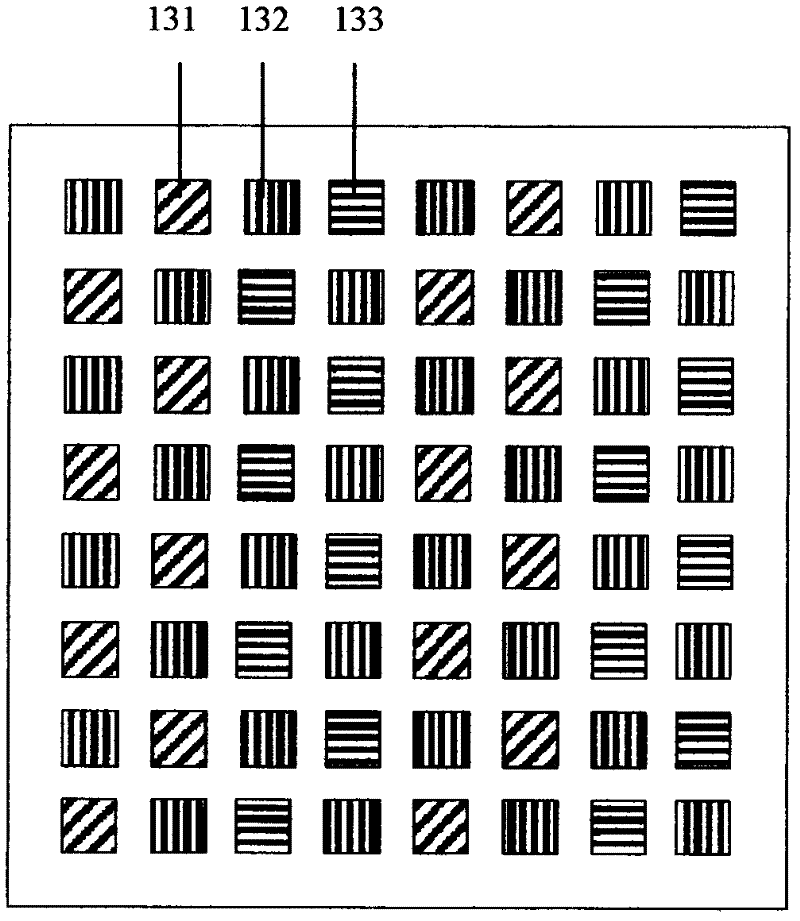

[0025] A kind of LED lighting module, its cross-sectional schematic diagram refers to figure 1 , which is characterized in that it includes an aluminum nitride ceramic substrate 11, an electrode 12 is arranged on the aluminum nitride ceramic substrate, and the electrode 12 is divided into a positive electrode 121 and a negative electrode 122, and may also be a positive electrode 122 and a negative electrode 121. The electrode 12 is provided with a three-primary-color LED chip array 13 , the three-primary-color LED chip array includes a red LED chip 131 , a green LED chip 132 , and a blue LED chip 133 , and the three-primary-color LED chip array is arranged in a Bayer manner.

[0026] In this embodiment, the Bayer arrangement is as follows figure 2 Schematic, it can be described as: the three-primary-color LED chips are arranged in the order of "...red, green, blue, green, red, green, blue-green..." in the odd-numbered rows, and the three-primary-color LED chips in the even-nu...

Embodiment 2

[0033] The present invention also provides a method for manufacturing an LED lighting module, comprising the following steps:

[0034] An aluminum nitride ceramic substrate is provided, and an electrode array is fabricated on the aluminum nitride ceramic substrate;

[0035] Provide a three-primary-color LED chip array, and arrange the three-primary-color LED chip array on the aluminum nitride ceramic substrate with electrodes fabricated in a Bayer manner;

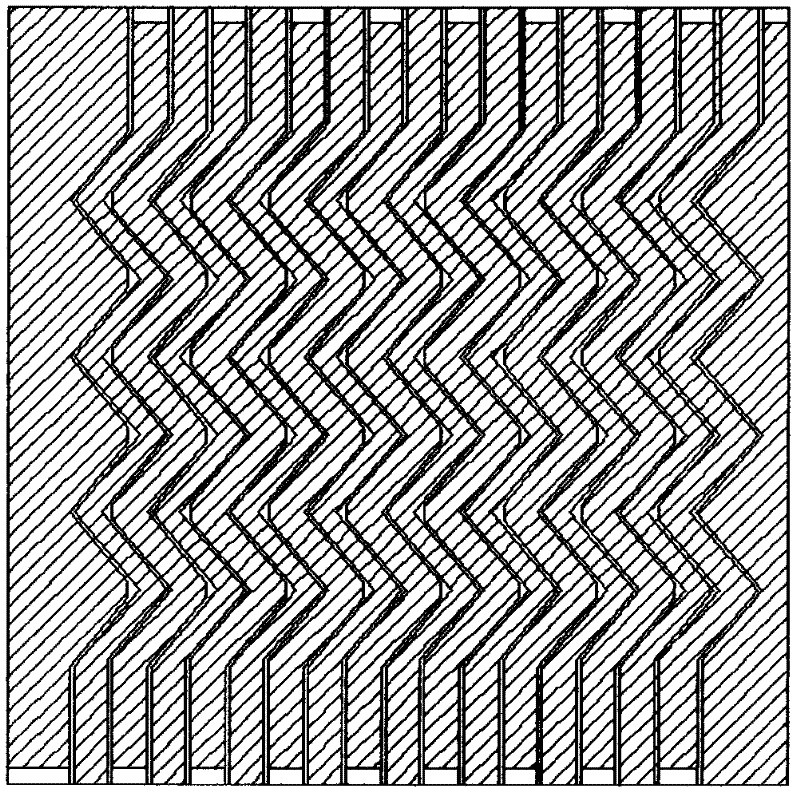

[0036] Using the electrode array to connect chips of the same color in the three-primary-color LED chip array in series and / or in parallel.

[0037] In this embodiment, the Bayer arrangement can be described as: LED chips of three primary colors are arranged in the order of "...red, green, blue, green, red, green, blue, green..." in odd rows, and in even rows The three-primary-color LED chips are arranged in the order of "...green, blue, green, red, green, blue, green, red..."; of course, the order of the odd-numbered rows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com