Test device for time varying mechanical properties of column under load-environment coupling effect

A test device and mechanical technology, which is applied in the field of civil engineering, can solve the problems of recording, unable to simulate the use load of structural components, and not considering the influence of environmental effects on the mechanical properties of components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

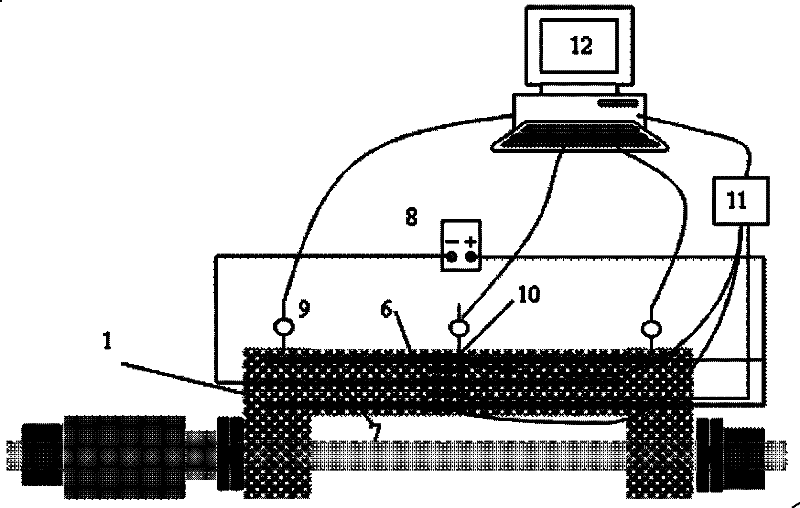

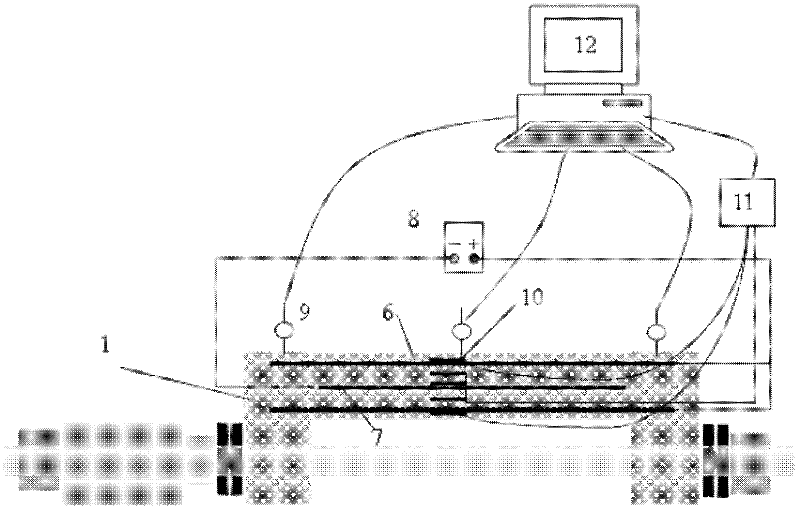

Embodiment 1

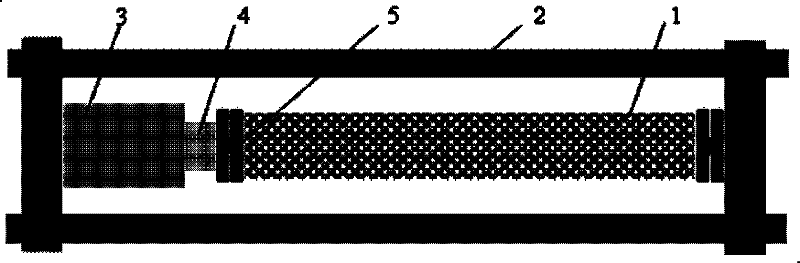

[0034] (a) Fabrication of reinforced concrete columns. The section size of the column is 120×120mm, the height is 750mm, the main reinforcement of the column is 4φ10, the stirrup is φ650-100, the protective layer is 15mm, and a plastic sheath with a length of 600mm and a diameter of 1.5mm is connected to the end of each main reinforcement Copper wire, the wire is first wound twice on the main reinforcement and tightened, then soldered with solder, and finally wrapped with epoxy resin, and the main reinforcement strain gauge is pasted in the longitudinal middle of the main reinforcement. Plastic sheathed copper wire. Bind the main reinforcement cage with steel binding wires, and then pour concrete to form it. When pouring, a φ6 stainless steel electrode 7 with a length of 450mm is embedded inside the column. The electrode 7 is connected to the outside of the concrete by wires. After 2 days of molding, the mold is removed and cured in a standard curing room for 28 days.

[003...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com